I bought a bunch of this, if anyone has any interest in it. Not exactly easy, but it can yield very cool results. Shoot me a PM if interested at $50 / yard, shipping from the US.

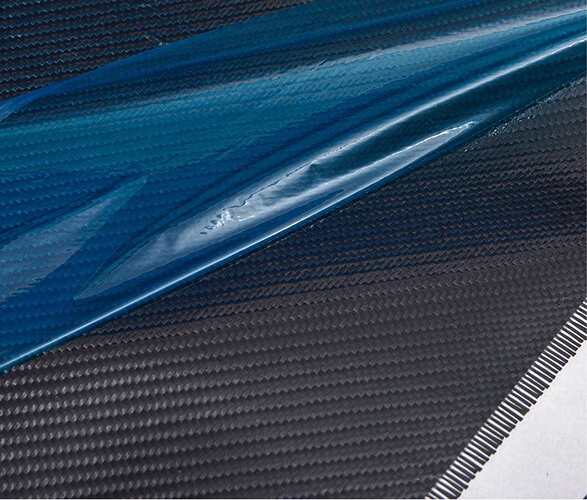

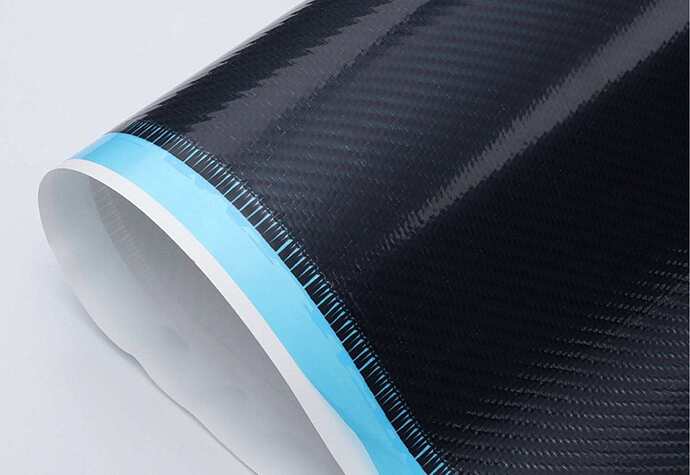

Prepreg - 3k 2x2 Twill Carbon Fiber Prepreg Fabric with Epoxy Resin

Out-of-autoclave prepreg carbon fiber fabric for making small or large parts. This is an uncured prepreg material and requires an oven or autoclave to cure it. It can be cured at 250F. A small toaster oven or conventional oven works great for small parts. A DIY oven can be made for large parts. Make your own high quality carbon fiber parts.

This material must stay frozen or it will cure and become brittle. Make sure you have a freezer big enough or plan to use it within 20 days. The colder you keep it, the longer it will last. You could cut it to smaller pieces and store in conventional freezer.

Yarn Warp: 3k

Yarn Weft: 3k

Weave: Twill

Dry weight: 200 gsm

Resin content: 40%

Total weight: 330 gsm

Thickness: .28 mm

Width: 1000mm (39.37")

Length: By the yard, cut to length (36" or roughly 1 meter)

Suitable Molds/Tooling

Molds/tools should be epoxy-based composite molds, epoxy tooling board or metal. In all cases, molds must be temperature stable to a minimum of 85°C but ideally to 120°C.

Fully Compatible:

High temp epoxy hand-layup molds

Carbon or glass fibre prepreg molds

Epoxy tooling board (high temp)

Aluminium / stainless steel molds

Toughened glass (for flat sheet/panels)

Storage and Handling

When not in use, prepregs should be kept frozen at -18°C (0°F) in sealed plastic packaging. When ready to use, the material should be removed from the freezer and allowed to thaw fully to room temperature before being removed from the packaging.

Remaining material should be re-sealed before returning to the freezer to avoid the risk of moisture uptake.

Cure cycle:

1 hour ramp to 80C

1 hour dwell at 135C

40 minutes at 140C

30 minutes at 150C

1 hour ramp down to 130C

heat off cool down