Hi Lars, looks like you got a more sophisticated epoxy curing station like I do. My print is fairly thin and mainly just for optical evaluation. But I think I will still make some tests with 1/3 power or so. Lets see if your epoxy layer keeps the props from bursting. Did you try CF reinforced PLA yet?

Yes, the previous prop was both CF filament and CF laminated. Laminating works really well and the props can be super thin - but fragile, hence the ice delamination.

im goimg to try this one ou in the upcomming summer and let you know

Ill maybe cut it down by a little as it wont fir in my hub or ill make the hub slightly bigger

Did you test the prop already?

general question on the flipsky 65161 motors there is no Screwed shaft version like the maytechs have right?

KR and thx

My first test with this diameter/hub will also be this summer. My PM-setup with the same blade design was V1 for past summer, this summer will be V2 with flipsky 65161 and this prop. I have the Flite board prop as well for the flipsky motor.

Threaded shaft is available at BG.

Ok thx very much!!

Lets see how it turns out

may i ask where you got the file for the end cap ?(torpedo)

KR and thx

I put it together myself in a matterhackers app called ultimaker.

My 65161 FlipSky has a small threaded hole in the end of the shaft to secure a cone termination.

Thx very much for your reply!!

Hello guys.

Im trying to make propeller for my efoil based on torqueedo desing but i need help…

Dont know how to finish it, dont know how to sharpen the edges.

Can anyone help me finish it?

here is design i made so far.

https://drive.google.com/file/d/1-EmeP48EseR3gbErXDNqYog7xNm14YyE/view?usp=sharing

Have you tried it (noise, speed, …) ?

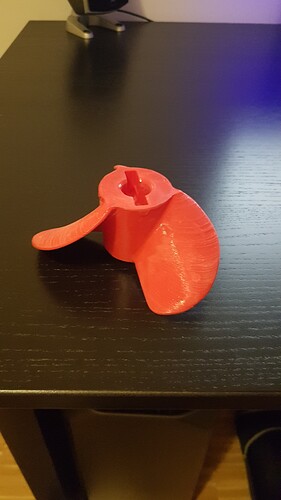

So I designed my own prop… wondering if it will work…

Made with only two perimeters with PLA+

I covered it with epoxy. I put the prop in a bag then I did the vaccum into it. The epoxy is well pressed against the prop but some sanding are needed after

Only 250w power… ![]()

The water level was not high enough

Hello guys…

Anyone wanna try this propeller just for fun?

https://drive.google.com/file/d/1gga05Th9Wl6dVLxr5q_WHd-kiIejTGJh/view?usp=sharing

https://drive.google.com/file/d/13itG0JnUzJHBFGESfXJ8dGayr7XTml3p/view?usp=sharing

Two blade and three blade version…

Diameter is around 170mm

Pitch is around 130mm

I think there is very little hope (almost zero) that such a propeller will outperform the cheapest and best commercial propeller in the EU, the Flite propeller. It is much easier to design a wing. Are you planning to do that?

Im not trying to outpreform fliteboard propeller.

I know i cant.

I need propeller for my diy efoil.

All propeller here have to big pitch for my setup, thare is almost no two blade propeller avalible, and i think two blade will preform better for my setup, so i designed one, and shared if anyone wanna try or have a need for similar prop.

If I recall correctly, you used a gearbox for the drive system. This gave you more torque (compared to a motor without a gearbox), which is very suitable for the Flite propeller.

Yes, i have geard design but my motor is 56104 790kv geard with 4.25:1, 185 kv on propeller shaft.

With this moto and gearbox i only have about 7-8 Nm of torque.

Is is fast spinning setup, so i need custom propeller that matches my setup.

Im planing to buy 500kv that others have used, but wanna se if i can get this one flying with custom propeller.

I habe tryed few versions but didnt have speed to get on foil.

I think 185 kV on a prop shaft requires a propeller with less pitch (not more pitch as you write above), but those RPMs are too high for any propeller (custom or commercial) anyway. Therefore, a 500 kV motor will undoubtedly be beneficial, but the main problem I still see is that you want to fly your own propeller at all costs.

Yes you are probaly right it is easyer to just buy and use tested stuff, but whare is fun in that.

I like designing stuff, practicing my 3d modeling skills, thinkering and experimenting.

I will order 500kv motor for shure but still i wanna have fun trying to make this work…