concerning the temperature, I don’t exceed 53° on my 13 to 19 km outings (12s12p battery). As for watts/h, the métro.pro works 1 time out of 2, so I’ve stopped consulting the data.

I also have a question:

What are your cutoff start and off parameters on your VESCs? because I stay on my so on every street…

Thank you and good riding

That’s sounds pretty good.

I’m pulling max 100amp, but even at 60 amps continuously it will reach thermal throttle of 80°C in less than a minute. As soon as I slow down the temp will drop rapidly, but never below 60°C.

What cut offs are you meaning?

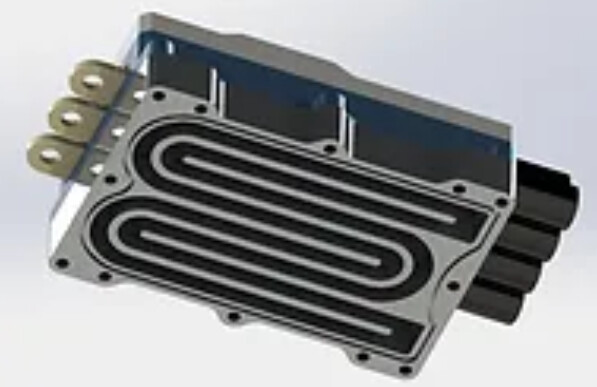

Can you give some information or picture of the PCB design with improved thermal transfer?

Thanks

My Raiden7 died on my last session.

I filled my entire enclosure with 500ml mineral oil to help with cooling and it worked good for one session reaching about 70°C then quickly dropping down to about 40°C. Had over an hour without any thermal throttling.

On the next session I was seeing similar temps as the first for 30 mins of use, then it would go for 30 seconds, and cut out (not thermally throttle). After 30 seconds I could go again, but only for 30 seconds or so. Current seemed to be limited to about 3/4 of what it was initially as well, so I’m assuming something blew or failed.

Waiting 20 mins for everything to cool to try get home on foil gave the same result.

@zesc what is you refund policy?

Even with a suitable water cooling, if the R7-Pro was undersized for efoil use, let’s hope the brand has the courage to say so on each R7 product page.

Hmmm clicked on your link and the picture is NOT on your homepage.

You also don’t have the “PRO” listed as an option to buy or have any info on it at all that I could find.

Posting messages that have have errors in them isn’t a good way to promote your product imho.

I stand corrected.

However the “coming soon” marketing ploy that’s so common these days irks me.

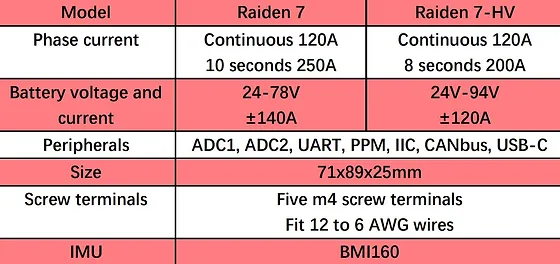

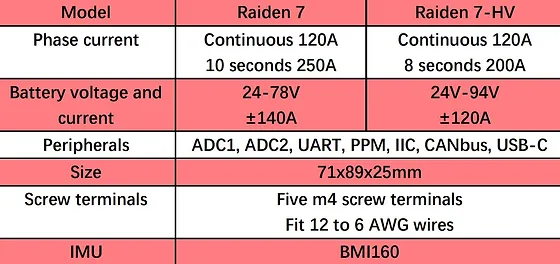

@zesc, this is the spec from your webpage - 120amp continuous, but now you say only it’s only good for 30-80 continuous?

This rating is the reason why I bought the controller.

Again, what is your refund policy?

Hi Mark, let me PM you.

Maybe. waiting on a refund, but had to send the unit back to them in China.

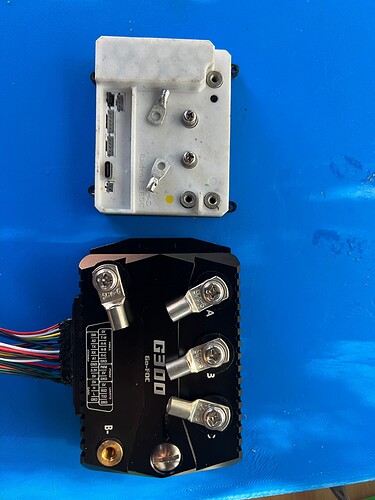

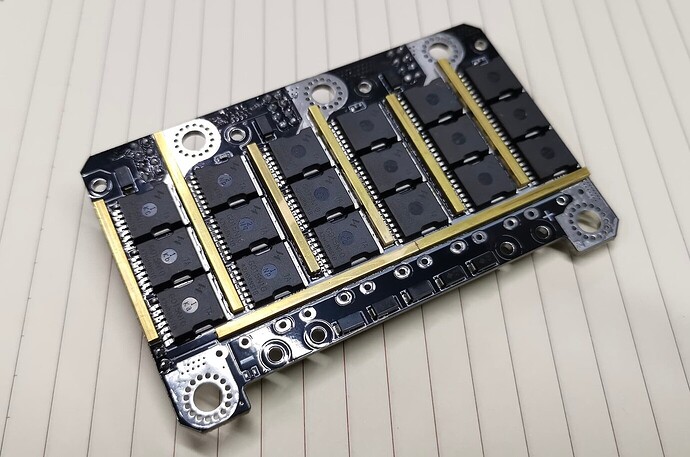

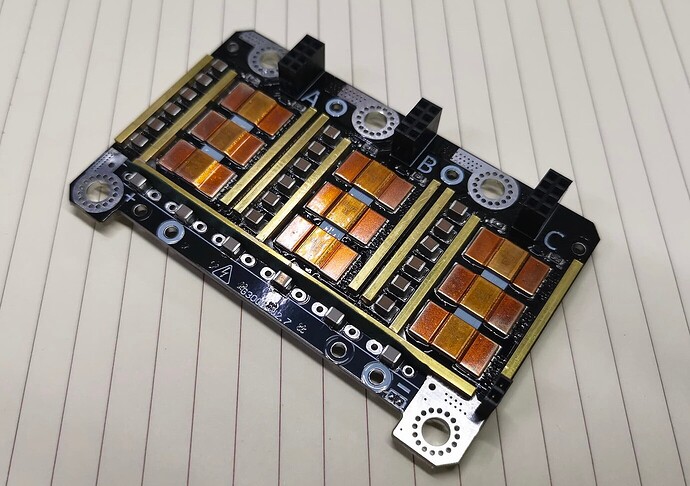

I since ordered and are using a makerX G-300. Completely different beast. Here are some comparisons.

I sent the controller back to ZESC when I was in China a couple of weeks ago. They have received it, and now are arguing about giving a refund, saying they need to continue evaluating the unit, they have had it over a week.

Their last email was complaining how I did not send back the Bluetooth module (I forgot, it’s still in the wrapping)

If I don’t get a resolution in the next 24hours I’ll process a refund via PayPal.

Avoid this company and their products.

It’s apparently so hard to realise for manufacturers that they build both parts and their name. Can’t have one without the other and be succesful for any longer amount of time.

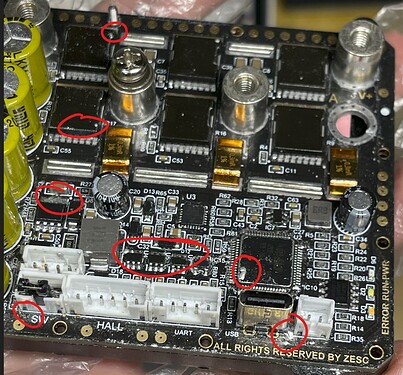

Hi, our engineer inspects the board. The terminal is either destroyed by external force or a loose screw which has huge contact resistance.

Here are the reasons.

- ESC will cutoff output at 100c, but solder starts to melt at 180c.

- There is no burn sign on Mosfet and PCBA.

- As circled in the picture, there are many thermal past which looks like liquid metal. This is very suspicious. Might cause short circuit or other issue.

Normally we can’t give any refund on such condition.

Anyways, it’s not easy for you to bring it back to us. We offer you either partial refund or replacement, but you insist on full refund.

BR,

ZESC.

I would guess that the liquid metal is molted solder from overheating. This could imply that the thermal measurement on this design is not at the hottest part. I’ve seen this on other designs when i borrowed a FLIR camera and checked my esc, at full throttle there was a huge delta between the temp measurement and the hotspot in the esc.

If so, then this is likely a design flaw, not a user fault as there is a temp protection on the esc, (or the setting in the VESC was too high.) This is not difficult to verify if you/we want to.

Those liquid metal on the board is still soft, definitely not solder.

Can I ask you a question.

Do you know where is the thermistor on PCBA??

No, but i hope you do?

I am not bashing your product, just stating the obvious: it’s not really likely that “strongarm” opened the ESC and poured liquid metal in it to destroy it - any problematic item or material that is there was part of the original design, don’t you agree?

The spatter that is there could be explained by overheating something, causing solder to flow freely. The terminal seems to have no solder anymore so that’s one place it could come from. If it’s not solder then it’s a bit of a mystery…

I am speculating, yes, and you know the design by heart and have it in front of you. What is your theory on the metal spatter? What is it and how did it get there?

Hi @ZESC - I assume you want to have the conversation here rather than by email.

The soft metal looking stuff is most probably thermal paste that I used between the zesc and my aluminium heat sink. This is thermally conductive, but electrically insulating so not the cause of any issue.

When cooling via thermal paste and and an upgraded thermal pad didn’t help with the cooling, a put some mineral oil in the bottom of my case in attempt to make it usable and not overheat. I was on holiday and running out of ideas. This worked great for an hour of use, the highest temp I saw was around 60°C.

On my next use of the vesc, the motor became erratic and then died 1km from shore, I’m assuming this is when the phase terminal desoldered and broke. On disassembly I had to use pliers around the phase terminal (it was completely seperate from the PCB) to remove the screw, and lug) so there was no loose connection/ high resistance here.

Zesc, you just posted some info on you new pro vesc, with a cooling set up showing it running at the stated specs. Can you do the same with the Raiden? Showing it running at 120amp continuously? With the standard pad. As shown in your spec sheet. I bought the Raiden based on your spec sheet which is a lie.

My max current was set at 100, but used approx 30-50 continuous, but the full 100 on start up to get out of the water. No where close to 120amp continuous.

Refund my money, the full amount with in 24 hours, otherwise I will open a dispute via PayPal, using your posts on this forum as evidence of selling a product that is not as described.

The heat dissipation of that one still does not look too good. (3rd and 4th image)

Correct me if I get the way this is assembled wrong, but the MOSFETs on the 3rd image are designed to put all their heat into the PCB below, not be cooled through the black housing. But as I see it, on the opposite side of the FETs are the current shunts? And the cooling is likely through the top of the FETs?

About the screw post desoldering itself, likely to overheating: I have not seen M4 SMD screw posts with more than 50A rated current… see e.g.: https://www.we-online.com/components/products/datasheet/7466004.pdf

From the first image in this thread, it also looks like the terminal that has failed was not fully covered by the thermal pad, making this likely one of the hottest areas on the whole PCB.

That paired with the fact that screw posts have a higher risk to develop high resistances mid-use by e.g. wrong tightening torque of screws, screws coming loose, wrong/insufficient mating cable termination (all compared to soldered joints) in my opinion thats just not a great joice for high-current diy applications. Except if each screw post is monitored thermally, which is not really feasible for such and application either.