OK, thank you.

…

…

There is a pdf assembly guide with all the part list in the folder

Great, thank you very much

Samisin,

I don’t have a way of accurately measuring it to the level you would require. My calipers don’t quite reach deep enough. The drawing I have from the Flipsky website is not fully dimension-ed. It is missing the large diameter of the cone that sticks out. The bolts seem to all fit as they should so it is unlikely a issue with my printer. I will dig a little deeper.

Here is the problem.

The small diameter on the cone of my motor actually measures at least 27 mm. The drawing shows the cone to be 24 mm.

In the photo I am pointing at the rub mark from where the small diameter of the cone hits. Yesterday I was looking around and I saw a photo that one of the guys posted of the same problem. He took a router to his print and fixed it. I am going to do the same.

This was the photo I saw. But it was Flightjunkie modifying a Reacher motor duct. Not the same issue.

That dock is for different motor. Let me check seems the drawing does not mach the their own motor

1101001010101

Hahaha. That was me. Yep. Still using it that way. Works good. Took all of 10 minutes to “fix”.

@MAC

This is weird! you have a drawing with 24mm dia con, your motor dia is 28mm, the drawing in their website shows 28mm and my motor is 24mm dia

Could the diameter depend on seal type used? 24 mm for lip seal and 28 mm for ceramic seal

I asked my buddy to modify it for 27mm. will let you know

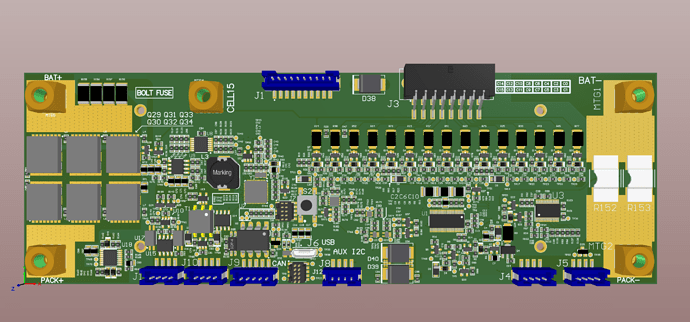

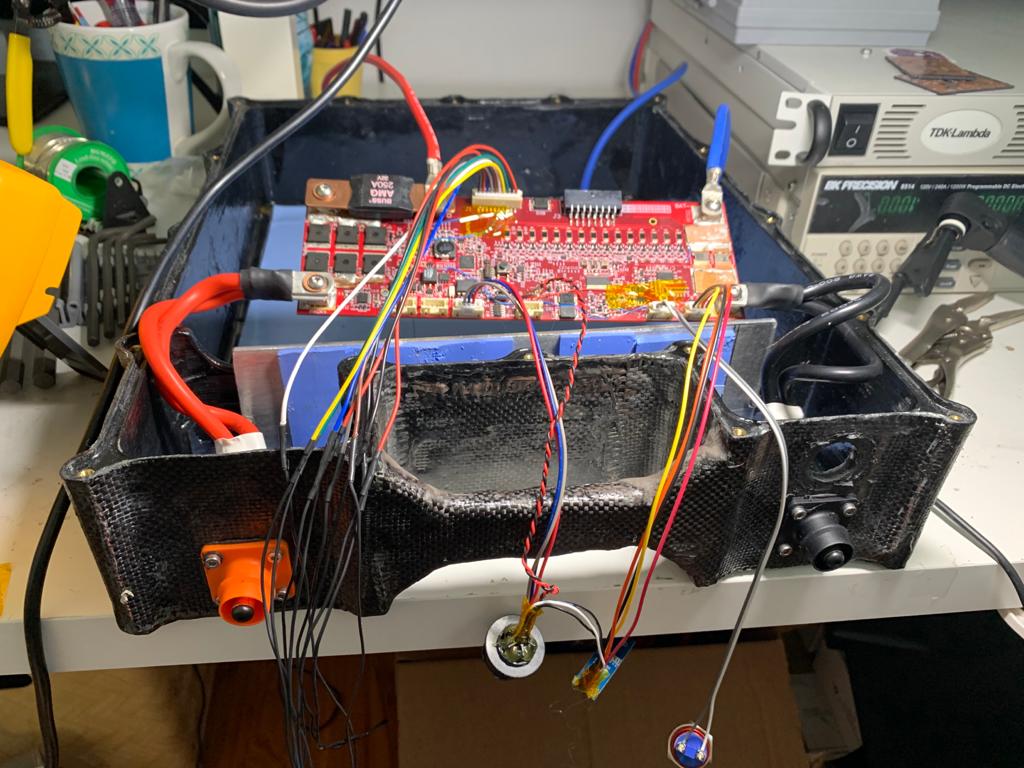

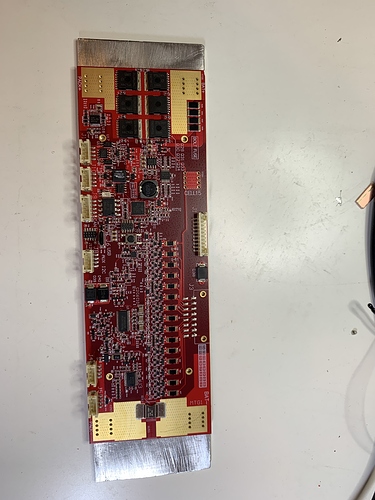

Finally the custom smart BMS is coming along. some of the features:

- Supports Li-Ion and LiFePO4 cells

- Supports up to 320Ah pack

- Up to 320 amps burst discharge ( timing depends on heatsink)

- Up to 320 amps continuous discharge (with proper Heatsink)

- 10 to 15 cells in series

- Up to 100 amps charge current

- Supports Standard CANopen fast smart chargers (delta-q ICL1200 and ICL1500)

- Supports non smart passive chargers

- Support Charge regulation based on the SOC (state of charge %) and Pack temperature for fast charge and pack longevity

- Accurate coulomb count Gas gauge with SOP, SOC,SOP, SOH,Cycle Counts and history of the pack.

- USB port for PC host application and firmware update and later host software

- Isolated CAN port with dedicated Wakeup signals

- ON/OFF Button

- Small OLED Display for main pack info

- Auxiliary isolated 5V 500ma output

- 2 Isolated emergency shutdown inputs (can be dedicated for kill switch, water leak sensor…)

- Auxiliary uart communication dedicated for Bluetooth or IoT gateway ,IoT gateway module is under development

Hardware Protections: - Fast configurable shortcut protection

- Fast configurable overload protection

- x2 configurable Battery pack temperature protections

- x1 configurable high current switches temperature protections

- Cells configurable under voltage protections

- Cells configurable Over Voltage Protections

- Inline last resort fuse protections

Firmware Protections:

- Pack discharge Over current protections

- Pack Charge Over current Protection

- Extra x2 High current fets temperature protections

- Extra x2 Battery pack temperature protections

Below is the short video in action while charging with icl15000 charger. I was only be able testing it up to 55 amps continuous in water thank. Hopefully next is to put my pack in and test in water

https://drive.google.com/file/d/1DqsEY6j_TyS62RU7q2K-frIm5cIt8gYl/view?usp=sharing

Wow, you are clearly enjoying the electrical side of an efoil build!  Keep up the good work! I hope all this effort is not only for a one-off build?

Keep up the good work! I hope all this effort is not only for a one-off build?

Nice. When will it be available?

Do you have a price ?

I am still testing it. For low quantity around 100 units cost per unit is around $300 which doesn’t seem to be feasible for DIYers unless you want to have a high end bms for this price. I am also working to reduce the costs while working on the software and firmware features

You’ll break that mast so easily, i have the same gong mast and it’s not robust even before cutting.

It will be ugly when it breaks, please take my word and reinforce it before use!

Either a couple of layers of glass fibre or some bracing plates would do it, you’ll anyway cover it with your motor mount - it won’t be dragging or visible.

Even simpler would be to glue a solid metal brace into the unused mast channel.

Nike!

I am looking at it now and I should say you are right. What if I enforce the motor holder clamp that covers the same section? I can do couple of layers of carbon fiber glassing on the 3d printed clamp that holds that section

thinking about it, and being lazy, i’d glue a piece of steel bar or alu as thick as possible in the unused channel (if you don’t need that for water cooling tube).

I find the gong mast on the thin/flexible side so you’d win some overall stiffness with that.

Holder clamp carbon overlay would work too but harder to know if it’s good since there’s a 3d print in there where the mast needs support