I want to open a discussion about my not straightforward journey, maybe someone in a similar situation can find this useful also i didn’t find a discussion like that in the forum, Enjoy!

My build is a work in progress, if I’m doing something wrong or if you want to know more about something let me know, i’m more than happy to provide more details (or help), I would also advise new builders like me that even if you have some knowledge, some things may not go as planned (will see later why ahahaha).

After some time i finally decided to build my efoil board. Since I am a student my main goal is to keep it as low-cost as possible. I would start by saying that I have some EE background so for me some choices were simpler and more cost-effective than others.

COMPONENTS LIST:

- Board: Used Tribord surf ~30€

- Foil: Aztron Rocket 1450 ~250€

- Motor: Aliexpress sensorless 6384 ~65€

- Inverter: Cheap FOCer 2 ~50€ (1 board)

- Battery: (not yet sure) 12S5P INR21700-M50LT (~1kW/h) ~200€ (only cells)

- Controller/Remote: Custom PCB that manages throttle input + some extra features

- Misc: Wiring, Connector, Sealant, Resin… ~200€

Now, let’s discuss more about my gained knowledge, thoughts, and future modifications to my build.

Foil/Board: Since I’m pretty lightweight (~60kg) almost any foil and board combination will work (I guess?). I read around that too much surface area is not very good for lightweight riders like me however until now I have zero experience in the water.

Inverter: Pretty simple, it is a Vesc 6 based inverter until now in my test I had no problem, judging by the power components choice I think that with minimal heatsink will drive the 4kw peak motor without problems.

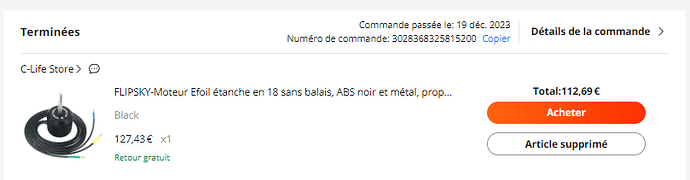

Motor: Ahh that went bad… Let’s start by saying that in the beginning, I was undecided whether to choose the 6384 or the “waterproof” 7070 by Flipsky. The 7070 motors should be in theory already waterproof however even without a prop it costs more than double the 6384 (~150€), by searching on the forum I found a guy’s post showing signs of rust in his motor, also props choice seems not existent. The 6384 on the other end was cheap, pretty well tested, good prop selection, the only downside was the waterproofing part.

If the waterproof part was still a problem in the 7070 motor why spend more than double for a motor that still needs waterproofing? So, I bought this 6384 sensorless motor from Aliexpress, around 65€ shipped, works pretty well when arrived, the problem began in the waterproofing part. Not as simple as I imagined… After I fully disassembled I saw PowerGlider post however, since I had neither a vacuum pump nor a fridge compressor I decided to use a simple paintbrush to coat the stator. I masked the critical part, mixed the epoxy, and covered the stator and the outer rotor with a thick layer. After the epoxy is cured the problem starts, when free to move the phase wire moves in a way so the backplate can be fully inserted, when fixed in place by the epoxy however they become rigid making insertion impossible. At this point, I tried to gently break the epoxy that held in place the phase cable without success. The stator is now immersed in a solvent to dissolve the epoxy (polyurethane resin), this can damage the lacquer in the phase wire. At this point, the main solutions are: to buy a new 6384 motor and find another way to epoxy it without special equipment or rewind the stator that i currently have with the same winding configuration. Until now I think that I will try to rewind it, maybe in a star configuration (should archive less speed but higher torque) however if I find a way to epoxy it in a cleaner way that does not involve complex machinery (vacuum pump, lathe, cnc ecc) or fully disassembly of the motor I prefer to start with a new ones.

Battery: Sizing an accumulator, especially in larger projects, is always the critical part of the project. Incorrect sizing could cause powertrain malfunctions and in the worst case could put people’s safety at risk. Personally, it is not the first time that I have designed an accumulator so I am already aware of the basic rules. On the internet (even in the forum), I find a lot of designs made of high discharge rate cells. Some of them are made up of 10 or 12 parallel cells capable of delivering 35 amps, which causes the battery to weigh like 7kg and cost around 700 to 1000€ which is a lot for a 1.5kW/h accumulator, also, does a 4oooW peak motor really need 240A continuously? I think not ahahaha.

I was keeping an eye out for these INR21700-M50LT cells. I read in some forums that this exact model caused some fire around the world, however, i think that was mainly caused by bad design. In the future, I will maybe order some of these cells to perform further analysis to see if they are safe for this application or not. In the meantime, i will not suggest anyone build this design.