Hi there! I am starting my first proyect. I recently bought a sss motor 790 kv. Now i know that there is another models with lower kv that give more torque. So i have two solutions now, i think, to buy a another one with lower kv or to assembly with a gearbox. Could anyone to post some pictures about how to rework motor shaft and assembly the motor with the super chief? I think is a good solution to introduce the motor to be waterproof inside a tube, because the diammeter of another one with lower kv is higher. And how do you do to seal the shaft? Thanks

All in built post : slow built from France

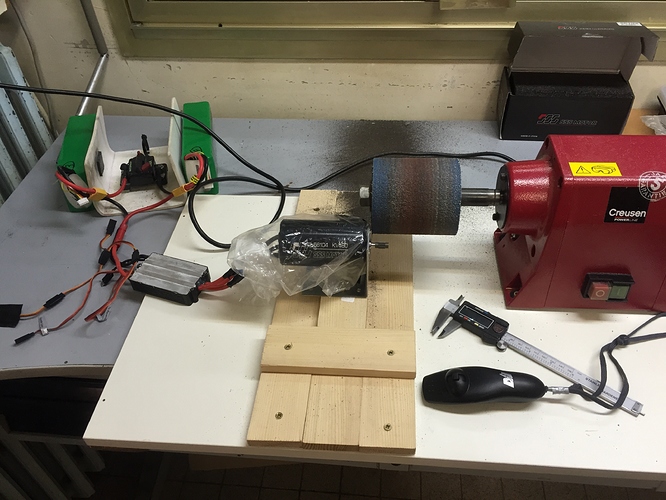

One way to do that :

Just a big mess and almost miss the 5.0mm but i did it , got the motor shaft from 10 to 5mm to fit the gearbox pinion

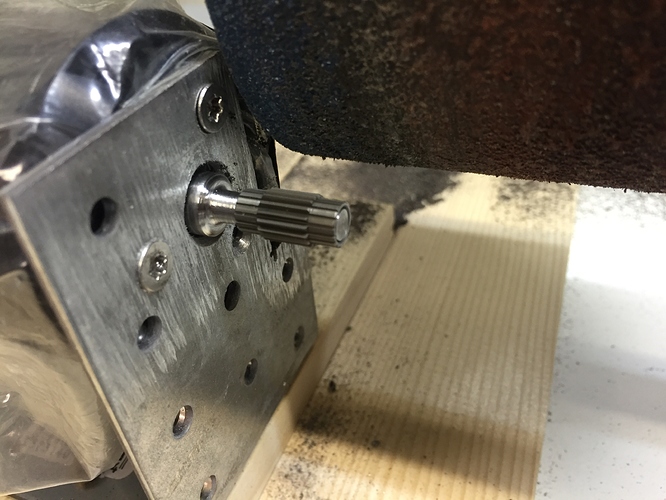

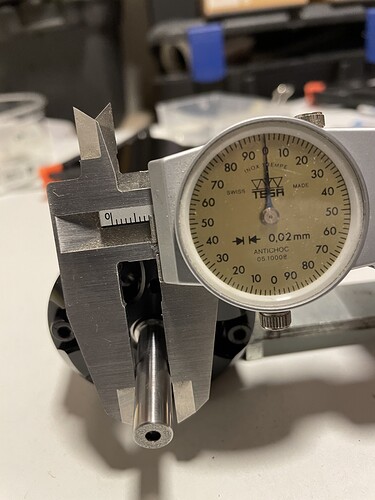

The shaft material of an SSS56114 is quite hard but not hardened. I drilled a center hole with a tungsten carbide 3mm drill bit. HSS center drill did not work, too hard material. Fixed the rotor with a id10 bearing, follow rest and a steel holder. After that I lathed it down with a rotating center. It took some time 0.2 mm each run. Used CBN inserts for hard material.

Hi @Alexandre and @sat_be Thank you for the answer! I know now how to rework the shaft! Two ideas are awsome. Do you have any pictures about the flange you used to assembly the motor with the gearbox? Could be really helpfull too! Thanks mates!

@sat_be : lol a lot better than me …

I used chef gearbox ( big one not made anymore ) , the one with a screw shaft at this end , the shaft was made by @Flying_Rodeo 2 years ago , I have a spare one if needed

For the super chief ( smaller ) I don’t know if someone made a setup on this forum …

Anyway you need I guess to get the adaptor for the airplane prop and rework it or put a coupler / shaft / bearing / seal / thrust bearing / prop …

Many way to do that , look at my built post , made 2 printed setup in sls but I never had success to get the motor housing waterproof with just o-ring , without glued everything

Inrunner can run wet but they will rust a some point , may be adding oil or corrosion x Will work for the year …

And not the least important thing , many prop a left hand so you will need to glued the gearbox and the flange to avoid it to unscrew inside the tube and twist the motor and its wires

No problem with a right hand prop

Thanks! I cant find the masures of the gearbox to check it. I am sending some emails but anybody answer. Do you know any gearbox to assembly in this motor?

The gearbox chief and super chief are screw on the same flange that is why you cannot find any measures

All you need is to check the bolts size (m4) and the diameter of the hole on the motor ( 30mm on the 56104) if I recall correctly

This flange I used is the one on the link so I will fit you 56

Pics should be in my post

After on the forum several built with neugart gearbox

I advise you if you are at the beginning of you built to get the 65161 or 65162 motor instead of building a geared setup …