Is it yours ?

What happened ?

Do you know the brand of thee brown V-ring ?

I’d be interested to know what happened too

I think Thom is speaking about the lipseal

Just riding along on the 5th time on the water and felt a terrible vibration. There was no impact to the foil or propeller. Fliteboard support is pretty good, they troubleshooted and determined it was a broken gearhead. They will send a replacement so thats cool. It could have been a long cold swim but luckily I had jetski support.

Bad luck I guess…

Can you spot the brand of the lip seal ?

Would you measure the outer diameter of the motor pod to be compared to the FR motor please  ?

?

Analyzing the patents, they seems to use Neugart gearbox with TPP motor, so OD should be pretty close to 60mm.

Also, do they offer a brand new replacement board or just replacing the pod ? What about the old / broken one, do you need to ship them back ? Interested in their after sale management

Hi MauiMan! sorry to hear of your issue.

What is shown in the picture above is not gearbox oil, it is simply shaft seal oil draining from the reservoir because the screws and o’ring that hold in the oil have been removed. These screws should not be removed unless under very clear instruction from one of our team.

I have never heard of one of our gearboxes failing, so this is news to me. Even test units that are over two years ridden for many hours a week old are still going strong. Yes our gearbox is made by Neugart, but it is a heavily customised unit to handle the forces involved to be easily replaceable.

I’d love to hear more about your issue and how you are going with the repair? Feel free to reach our to me directly at david@fliteboard.com. I don’t spend much time on this forum as I’m pretty busy with our global team and customers. Especially in these challenging times. I was alerted to this and particularly interested in making sure our customers are happy.

To your point on direct drive versus gearbox… We chose to use a gearbox because it allows us to use a narrower and smaller motor and still provide ample torque. The key here is to use the smallest motor possible, not the most powerful. This greatly reduces wettest surface area and drag, and improves responsiveness. This is Fliteboard rides and turns better than anything else (at least thats what everyone who has told us so far that has ridden Fliteboard and a competing product).

All the best,

DT

All good David. I had jetski support. Your support team was pretty good.

Why EFOILS are so EXPENSIVE? ft David from Fliteboard, a 44min video by JetsurfingNation.

Don’t hesitate to click on the video description to see the 16 questions with timecodes.

The Fliteboard efoils are exceptional products. For the people who can’t put so much money in their toy, we are fortunate to have this forum that allows us to built an efoil around a 63100 outrunner motor from 1500usd with a 12s12p LI-Ion battery (SAMSUNG 30Q).

![]() to the forum creators.

to the forum creators.

Maybe covered somewhere else but wondering about the flite board motor cooling, filled partly with oil like Lift directdrive? Is the motor outrunner or inrunner?

German scorpion made motor i believe and neugart 1:4 planetary

Thanks! Was not able to see from the pictures, is it inrunner or outrunner, scorpion makes both i think. As the motor is in a shell interesting that it does not have heating issues in any case.

I might be wrong but looks like the Flite has less water intrusion issues compared to direct drives, maybe the gearbox is the reason, maybe easier to make waterproof?

What is the external diameter of this motor ? Custom or stock ?

On the stock side, taking into account the 4::1 ratio, we’re looking for 125 x 4 = 500kv.

Here is a 350USD candidate (backorder): 12s max, 8mm shaft, 5 / 7kw continuous/peak power. The specs and price look interesting but the torque info is unknown and the waterproofing (or oil bath) implementation looks uncertain. What do you guys think ?

'Scorpion HKIII-5035-500KV (8mm) - Scorpion Power System

https://www.scorpionsystem.com/catalog/discontinued/motor/hkiii-50_1/HKIII_5035_500/

Pretty hard to put a gearbox on a outrunner and in a tube , the phases wires are in the way , works for airplane but I think its a inrunner setup, sss or tp have plenty of power , Scorpion not sure they have the thing

For a geared setup sss56104, 56114, 56123

US $176.72 6% Off | SSS 56114 360KV/420KV/500KV/700KV Brushless 1/5 Motor 13.000W 56114mm for Boat,car and Surfboard

https://a.aliexpress.com/_mqUfhuV

Or TP 5680 or 5690: TP Power TP5690 Brushless Motor for RC Boat or 1/5 Car and Truck | eBay

56114 and 56123 are only available with 10mm shaft, you need to lathe it down to 8mm.

KV depends on the voltage, planetary gear and propeller, 100-130x gear ratio prooved to be a good value for 12-14S

And you can use a tp4070 780kv gearbox 1:6 on 8s as well

, my first setup compared to FR :it was not bad at all even with no vesc

, my first setup compared to FR :it was not bad at all even with no vesc

Good points, you are for sure right there. Have been thinking about the water proofing of direct drive and why it is seams so hard compared to outboards/sterndrives. There is huge difference in reliability and still many outboards have extremely simple gasket solutions, why? Think there is 2 reasons.

- amount of oil. There is much more oil in the outboard/ sterndrive gearcase, sometimes the oil level is actually higher then the water line. Thus the pressure difference is much mot favorable, more like oil trying to leak out than water coming in…

- type of oil and less sensitive parts. Gearcase oil is actually designed to work somewhat OK even with some water mixed, nothing will be damaged even with small amount of water, same goes for teh bewel gear parts.

This said, none of above is really applicable on a direct drive motor, thus think its still very thought to make them keeping water tight for high hours/ years of usage with solutions seen so far.

Not sure where you heard Flite would be using an outrunner. They are using a TP power inrunner motor with about 400-420kv. That was from my calculations. You can find more infos on this on top of this thread. What I can say for sure is that It was a TP power motor. I saw the typical colors / geometry on one of their videos but can’t remember when/where.

NB : you can’t use an outrunner inside a tube unless the tube is non metallic. Otherwise you have induction currents in the tube happening every time the poles are switching. This is exactly how an induction cooking plate works. Don’t try this unless you want to cook something.

Actually did not hear such thing that they used outrunner motor, mainly asking what type of motor. IMHO less information available on Flite motor than on the Lift (and other direct drive motors).

Many thanks about the information about the induction currents, had no idea, always learn something new here!

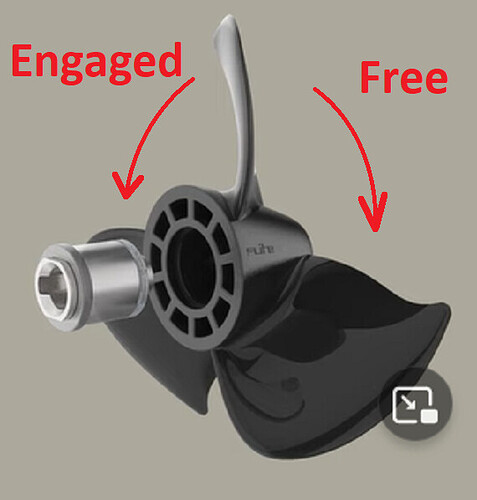

Wondering how a Flite True Glide propeller works ? In fact, a simple solution that acts like a bike “free wheel” mechanism but costs a finger: a spare True Glide prop is sold between 250usd€ and 500usd€ which is completely crazy since the prop without the bearing is sold 45usd€.

The trick is to hide a bearing in the propeller hub, a special type called “one way bearing”, “anti-reverse bearing” or “clutch bearing”. The units are compact, lightweight and operate directly on a shaft that allows the prop to turn freely anticlockwise and engaged clockwise, seen from the back when you (un) mount the prop.

Here, seen from the front, it is the opposite.

Corrosion resistant stainless steel one-way bearings do exist so that we, DiYers, can design a 3D printed prop around them …

https://www.bocabearings.com/products/bearing-and-ball-types/one-way-clutch-bearings?ProductType=0

With the appropriate tooling, it would be interesting to modify a 3 blade Flying Rodeo prop to accomodate a one-way bearing… just thinking…