These blades would be a bitch to mold if you want to keep fiber continuity up to the key sliding inside the extrusion…

A four-part mold: the bottom one in two parts opening along the female key and looking like the aluminium extrusion…

The blade hub (holder):

1- molded in 3D printed molds OR,

2 - custom extruded therefore costly because of small quantities.

The blade lock looks very clever, an aluminium blade would be easy to make.

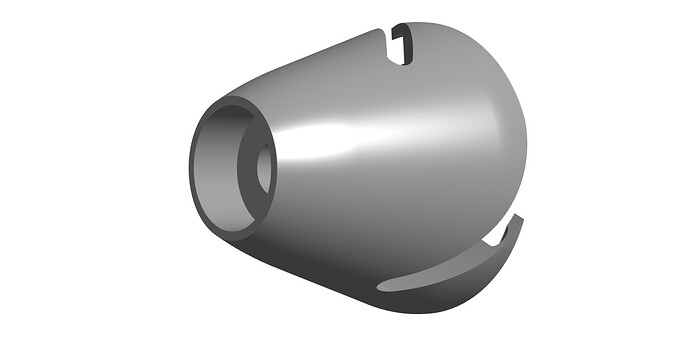

I’ve been looking at a similar issue recently too - quick and easy replacement of a damaged blade, easy to make a carbon blade. Here’s a sample hub

The shape and size of the hub matches the Flite propeller, but the blades (which I can’t show yet) should easily outperform not only the Flite propeller blades in terms of hydrodynamics, but hopefully the FR propeller blades as well. I am now considering several issues, including whether to patent the blade locking system.

Well, this is a DIYS Forum and benefits from sharing experience and designs–sorry but I don’t see the point of announcing patents here. Post and contribute, OR patent it and keep it secret.

As I said, I can’t show the blades yet …because I am considering patenting the blade locking system. It logically follows that if the blades are or are not patented, only then (perhaps in two or three months) can I show the blades.

However, it is also true that the ability to replace a damaged blade is ideal for any e-foil owner, and many different blade attachment systems can be used. However, only one of them can be the best, so it is worth considering patenting it. I think my system is very simple, very robust and very cheap.

It is a Modell flyer hub

I don’t really see the problem it solves, maybe good in a trials phase but people don’t regularly want/need to switch props. Or?

That is also what I thought. Maybe when you need to switch regularly between a safer family/beginner use with shroud to a foldable prop without shroud.

Yes, that’s a possible scenario

Apart from that i’d rather see a folding mast to avoid having to assemble before riding

In case one would need to buy a second hand LIFT efoil, it seems that the warranty is not transferable to the new buyer. Check twice and confirm with a written proof.

I don’t think that competitors like Fliteboard do that…

I can confirm that the warranty does not transfer. I must say though, that Lift customer service went way above my expectations in helping me get my no warranty having secondhand Lift 3 up and running. Buying used is always a roll of the dice, but the level of support I received turned a crappy roll into a good one.

I don’t think that’s satisfactory. I can imagine a customer having to sell their LIFT efoil after five months (motor seized with rust or battery no longer responding) and reselling it for half the price. You contact LIFT support and they ask for your name, and just whereas you could have pretended to be the buyer, when they hear you’re not, they happily tell you “We’re sorry, you’re going to have to pay for the parts that we’ve badly designed. As soon as you send us 2500USD, we’ll provide an outstanding level of support because you don’t have the right surname”.

A good reason to prefer another brand…

That wasn’t my experience at all. I had an issue with motor cogging the first time I put it in the water. The “seller” who was three hours away from me used the fact that it was under warranty and that the original dealer was close(ish) to where I live as a selling point saying that he’d serve as the go between during the remaining supposed warranty period. After completely ghosting me when his board didn’t work, I made the trek to the dealer to throw myself at their (and Lift’s) mercy, only to find out that the board was out of warranty by almost a year even if I had been the original owner. Not only that, but the original owner was notorious and had tried to scam the dealer by initiating a chargeback after he bought the board. He basically remained a thorn in their side for two years as they tried to keep him happy. Now all stories have two sides, but given the was the seller treated me and the way the dealer treated me, I’m inclined to 100% believe the dealer’s side of the lengthy story I got from them. Anyway, the dealer spoke with Lift and sent them the pictures and video I’d taken detailing the problem I was having, and Lift agreed with what the majority of the Lift owners the two Facebook groups were saying, that it was probably an e-box failure. Lift replaced to e-box at no charge to me and sent it directly to my house so that I wouldn’t have to make the drive back down to the dealer. The new box didn’t correct the issue and I made a trip back to the dealer where they took the time to further diagnose my board by trying a new data cable, new remote, new battery and then a new propulsion system. We were able to lock it down to a bad motor on my board.Since by this time I’d learned that the warranty period was up, I took the board home and contacted Lift to see if they’d sell me a new motor, which they did and at a deeply discounted rate. It arrived at my door two days after I paid for it. As far as I’m concerned, Lift treated me very fairly and much better than should be expected given that I was a second owner of a board well past the warranty period. Also, in my hours of haunting the various efoil Facebook groups (which are very much more active than foil.zone, if encountered far more stories of positive interactions with customer service than negative. It’s not even close in fact. This played a big role in my decision to buy a used Lift over a new budget brand like Waydoo or even Foil.

As far as the problem motor goes, I disassembled it and found a spiral clip had failed causing the rotor to shift forward and chew through one of the phase wires just below the stator. I’ve since repaired the wiring, replaced the faulty spiral clip with a spacer sleeve, installed new bearings (even though the originals were fine) replaced the housing o-ring, and will keep it as a spare. When the riding season is over, I’ll tear into the new motor and implement my spiral clip elimination sleeve in it too. I’ll admit that this simple fix is more robust and would 100% eliminate similar failures, but there are hundreds and hundreds of Lift motors operating as built and the spiral clip failure doesn’t seem to be a chronic one. It seems like I’ve heard of maybe one motor other than mine with a clip failure, and IIRC it didn’t result in destruction of the wiring. Water ingress is more common, but I’ve only heard of a few of these failures and most of those were handled under warranty. For the record, the dealer I spoke of is Houston Kiteboarding and they sell between 150 and 200 Lift efoils per year. We had a long talk about their failure rate and it’s seemingly well below what I’ve come to expect as a retired service technician with almost 40 years of tradesman experience.

This is a very interesting testimony. I note that LIFT support went to great lengths for an item whose warranty expired a year before.

I do believe that LIFT efoils are of a very high quality, but why ruin their excellent image and by saying that there is no guarantee for a new purchaser under guarantee while offering a top quality support when the warranty has ended a year ago ? I don’t get the point. The only explanation I see is, they are not required to anything and can stop overnight without notice.

How did you repair the motor wires? I have a motor like this but to get down to the wires is a mission.

It was difficult. The rotor had contacted only one of the three phase wires, and had only partially worn through that one. I’d say that half of the enameled wires on that phase were parted. Since individual strands of magnet wire have an enamel coating, I searched for something that would chemically remove the enamel but nothing I tried would touch it. I then followed some instructions for removing it with molten solder and that seemed to work pretty well. The process involves building up a ball of solder on the top of an iron and then spreading it over the wires that you’re trying to clean repeatedly, allowing the contaminated solder to stick to the tip of the iron, and then repeatedly cleaning the tip. I did this (and brushed flux on) until solder finally seemed to want to stick to the wiring, and since there was some intact strands of the twisted conductor remaining, I bridged the broken strands along them with a buildup of solder. I pushed this repaired section down into the motor just a little to improve clearance to the rotor and to see how solid the solder repair actually was. Once I felt comfortable with the repair, I cleaned it up with acetone and then painted on multiple coats of “liquid electrical tape” over the wire and solder. I also bridged the repaired wire to the adjacent wire with an abundance of the paint on tape to provide support. All of this was done working through the top of the motor with the soldering iron, a long thin paintbrush, and some long wood handled cotton swabs.

Since the soldered area was built up significantly with the solder and tape material and was then pushed down and inward some, I made a test shaft on my lathe to put down into the front bearing (front considering the direction of travel) so that I could make sure there would be ample clearance between the wire and spinning shaft with the sleeve/spacer on it. The sleeve was made of 12mm ID 304 stainless seamless tubing cut down on the lathe.

I will say that I haven’t tested the motor under power yet. I was tempted to swap the new motor for this one, but to be honest I just want to ride the board at this point. Here in southeast Texas I still have a couple of months of warm weather to take advantage of and I’ve got a lot to learn.

Cleaning wire insulation can be done with molten NaOH salt bath as a final solution, it’s a bit dangerous since fumes are highly caustic, needs filter mask and protective clothing and outside ventilation, but it works on everything and leaves the wires sqeaky clean.

Straight from the source of information: Lift Foils | eFoil Electric Surfboard | Warranty

How Long Does My Warranty Coverage Period Last?

The coverage period begins the date of retail purchase of the Product and ends:

*Two years for components comprising the board, as are further be described

in the Product’s manual(s);

*Two years for all components comprising the foil and wing, as may further

be described in the Product’s manual(s);

*The earlier of two years or 600 battery cycles for the Product’s battery.

If I Sell My eFoil, is the Warranty Transferrable to the New Owner?

*No, Lift Foils warranties are non-transferrable and are only applicable

to the original purchaser.