For the last two years, I was designing and making a fully carbon e-foil.

The product came out so great, I have to share it and try to make a business out of it.

First, I have designed the e-foil. My next step was to CNC carve the polystyrene core, and then the real work began.

Since I was in the middle of building a house, I took a shortcut and bought the FR motor assembly from Slovenia. This is where I come from too, the land of e-foil pioneers  . Flying Rodeo rules.

. Flying Rodeo rules.

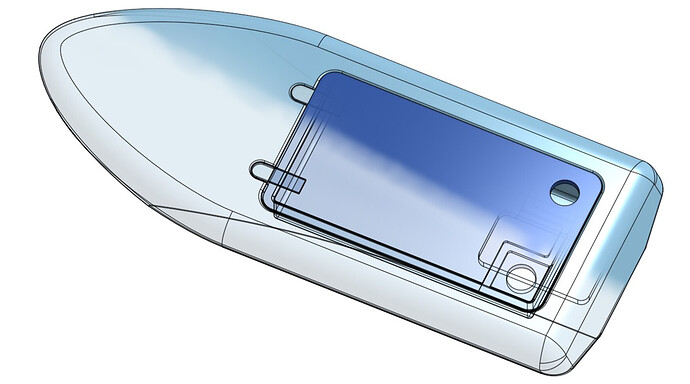

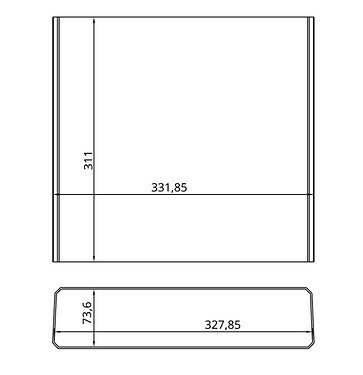

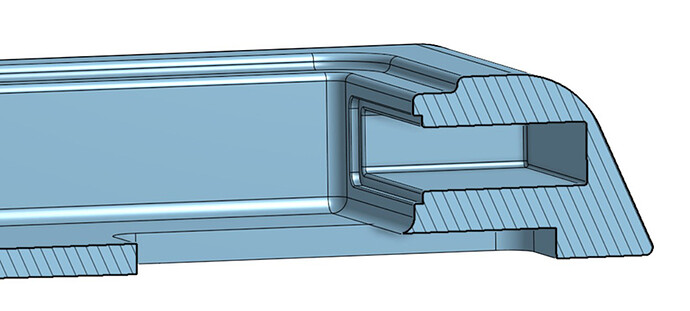

After curving the board, it was time to design the battery case. The idea behind the design was that even if I designed the case for a Li-Ion LG INR18650-HG2, 14S, 14P battery, anybody could adjust/cut the width of the carbon sleeve on his battery specification. I have also included another idea design-wise, and that is that all screws are hidden.

Disclaimer: Because of carbon being conductive, I have made the interior of the carbon sleeve of Kevlar, which is heat treated. Thus, is can bear high temperatures.

Time flies, so a year passed since I was working on other things, too, e-foil being my free time activity. I was lucky enough to meet Peter, who joined the project. Besides being an adrenaline sports junkie, he comes from financial sector and he has really good organizing skills.

After that, the project skyrocketed.

We finally had schedules, timeline and project management with regular meetings. I’m so grateful to Peter, because with his work we can achieve better and faster results.

Peter was also the testing pilot for the e-foil. We have made a few e-foils by now and now we are ready to hit the market.

We specialize in carbon and all kind of composite materials since I am an industrial and graphic designer. Everything is made inhouse except the electronics and the motor assembly.

We decided to start selling our first two products, which are the carbon fiber board for the e-foil and carbon/Kevlar fiber battery case.