Is anyone experimenting with a 3d Printed Toroidal Propellor? People are experimenting with them for quadcopter propellors, and their are some on the market for boats that make claims of increased efficiency.

Just some links for example:

Is anyone experimenting with a 3d Printed Toroidal Propellor? People are experimenting with them for quadcopter propellors, and their are some on the market for boats that make claims of increased efficiency.

Just some links for example:

The Sharrow propellers appeared in 2019 on this forum.

@Mab tested a prototype

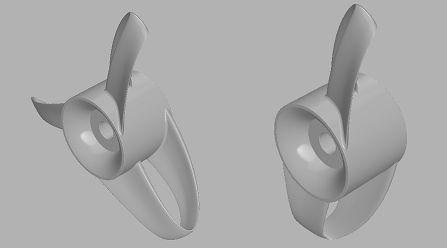

What is sure is that when this type of propeller is perfected, there will be less need for a duct and possibly no need for a folding prop ![]()

I was only looking at these the other day as they kept popping up on my youtube.

Found this type on thingiverse, I was going to download and dissect it in CAD to resize and alter the hub.

I hope it will be conclusive but the FR example with CAESES has shown that the blades need to be thin to be efficient and here it is not the case. The Sharrow patent posted on the forum show different airfoil sections with their respective angle of attack and loop paths that should be reproducible using a “Sweep” function or a spline on a 3D modeleling SW.

Maybe a bit ridiculous but I’m curious to know if you could expand on the toroidal design to balance a more organic model

Hi, looks good. Could you send stl data to me. I need it for 70131 motor. My experience with CAD is 10 years ago. I also want to try. Thank you.

All my friends have these motors burned out. You better take care of its waterproofing.

Can you share a step version of it? Would be fun to play with it and do some scaled versions!

Ok thank you, any way to waterproof it.

I think the weakness of the motor 70131 are only the screws. And therefore the screwholes were water can come inside after corossion. They are not stainless steel normaly. I let them changed by freerchobby directly. Because the motor itself seems to be a beast. Now I will, after the experience from your friends, seal them extra. Thank you for sharing this. My watertest will come in the next days.

Last August (2022), something started:

based on 66B2 2017 Toroidal propeller MIT patent

Until yesterday, I was sceptical about the Sharrow prop (water only) or toroidal prop or toprop (air only). Before yesterday, I kept wondering if this was a hype, if it at least held its promises namely Q1-noise reduction Q2- ability to generate lift to fly ?

Efoils already owe a lot to planes and it’s hapening again with drones.

Since early Feb. this year (2022), there’s an excitment going on, in the drone DiY community. This excitment is visible on different media like YouTube that show the designers or testers and Thingiverse that publish the STL files to be replicated throughout the planet. There’s a community design.

Here is a guy called Striking FPV (his Thingiverse page is updated every other day). In a first video tittled DIY MIT Toroidal Propellers for Cinewhoop FPV Drones???, he explains the rough design methodology about how to twist a blade like a mobius strip (see below), not a detailed guide but the overall process.

In a second video, tittled [MORE Toroidal Propeller Designs and Improvements for Drones]

(https://www.youtube.com/watch?v=hby6U47oV_k), he analyses his propeller misbehaviour and proposes corrections.

Answers to the above questions, and Feb. 2022 are only the first serious tests after the 3D models being released. As far as 2 or 3 blade flat drone to-props are concerned:

A1: yes, multiple videos show the average noise reduction is 3dBA, going in the right direction since my maths tell me that -3dB in log is a decrease by a linear 2 factor,

A2: drone with to-props do fly, there are side effects though. A.2.1 there seems to be too much lift which make the drone increase in altidude when wanting to go forward A2.2 motors are hotter with a to-prop.

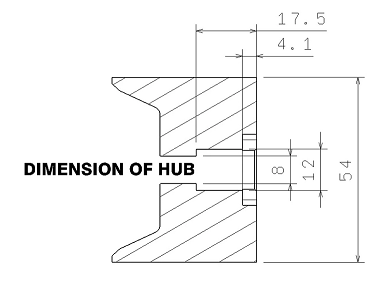

Then, what’s the link between drones and efoils ? The Sharrow prop uses sections following a path like toprops do ! @Larsb, rather than playing with a step file that could never come, let’s try to create our own based on a FR hub for Flipsky 65161 motor:

A propeller hub is designed like a skateboard wheel Tuto : Revolve tool - skateboard wheel - Fusion 360

When the hub is drawn, we can apply two boss/extrusions with a section in between that follows a path (sweep function). How to sweep a solid body, there’s also Mobius strip tutorial

The profile doesn’t twist on a sharrow prop.

@SUP-MIKE would you chime in and (re) explain your method ?

Sweeping and modelling is not an issue, got some years CAD experience. Time is the issue, haven’t got enough to do 50 iterations to get something worth it.

Hello, looks could so far. But if you look at the original blades they are upside down.

The blade leading edge of a Sharrow prop is not twisted like a mobius strip.

I’ll check the model, then upload as step and stl. Probably quite difficult to print well on your home printer due to the angles.

Yes I would print it over printing service for good quality.

@SoEFoil I do not mean twist the string itself. I mean twist from end of the shaft to beginning of the shaft. I bit hard to explain. The startpoint of the string is at the beginning of the shaft (nearer to the motor) to the end of the shaft(farer from the motor) Please compare the Model from Larsb with my picture there you can see that there is a difference. This is for right turning Model. I hope you know what I mean.

If the drawing from Larsb would be a left turning propeller, the string have to be loosen at the beginning of the shaft, then flip over that the bending is in the other direction. and then attached it again to the beginning of the shaft. So not a twist of the string. more the wrong bending direction of the strip that forms the propeller blade I mean. Hope this can help because sharrow propeller got the 3.Generation, and I think this is important for the good results. The picture with the original sharrow propeller shows an right turning propeller.

@Larsb I can print it on an MJF printer, shouldn’t have any issue with the overhang. Are you going to post the STEP file ,after you check it, here or somewhere else?