I found out that you don’t need a professional vacuum machine to vacuum bagging. I was able to laminate a board and a hydrofoil wing using a diaphragm vacuum pump that cost about $10.

To use such a pump, the most important thing is to have a whole vacuum bag, without holes.

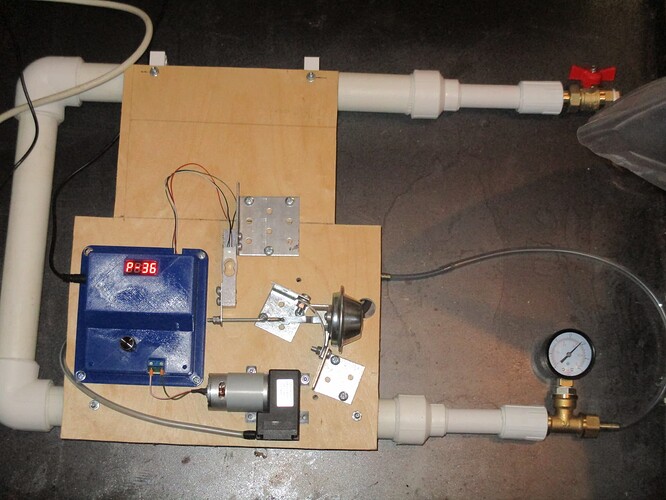

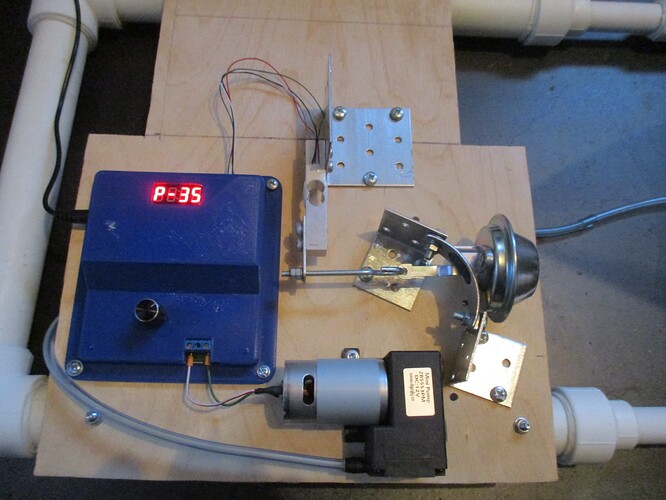

I assembled a vacuum unit on this pump. It includes the pump itself, a power adapter, a electronic pressure gauge, which I assembled from a vacuum membrane from a car and a strain gauge, a controller, a vacuum pressure gauge, and hoses and plumbing fittings. I assembled the controller based on an Atmega microcontroller, a digital LED indicator, and an encoder. A MOSFET is used to turn on the pump. I printed the controller case on a 3D printer. The entire setup is assembled on a piece of plywood. As a reservoir, I used several pieces of polypropylene pipes soldered together. This receiver was quite enough for me. As vacuum bags, I used clothes bags to vacuum the wings, and a mattress bag to laminate the board.

The photo shows me gluing the carpet to the deck using a vacuum. Previously, using the same setup and bag, I covered both sides of the board with fiberglass.

I do not recommend assembling a pressure gauge like mine. I just couldn’t find a pressure sensor at a reasonable price at first. Then I found suitable vacuum sensors on Aliexpress, but the setup was already assembled, so I left it like that. It works fine for me anyway.