PPM and PWM are different, however in this context are often used interchangeably. I don’t see why that knob wouldn’t work since I believe the VESC should recognize true PPM or PWM. What remote are you using? If you have a multimeter you could also try hook that up to your remote to see if voltage is changing, would at least give you an idea if something is happening. Though I think the problem will likely end up being software/configuration and not hardware.

Thanks Scripto. I do have a multimeter. I’ll give that a try. I also bought one of the potentiometer knobs on Amazon so I’ll be able to test that too soon.

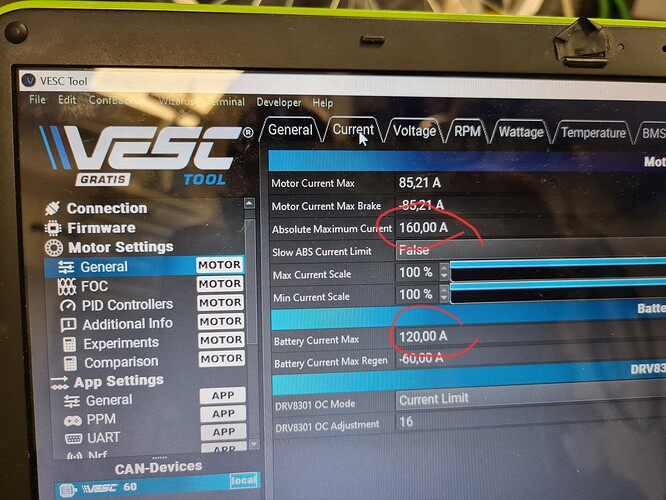

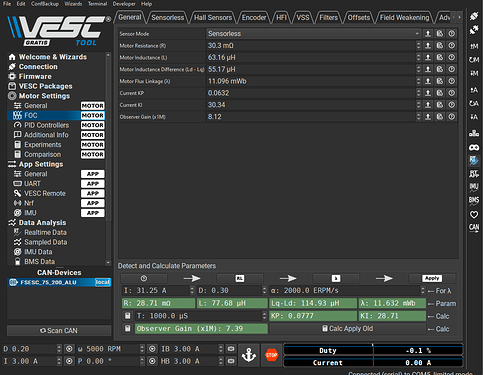

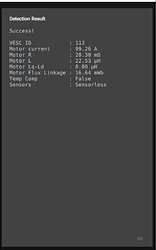

Hi, I need some advice. I can’t change these values (in the pictures) in the VESC tool FREE program. Is it because I have the FREE version?

If I download the bronze version, will it be OK? Thanks for the replies

Hi,

have a look first if you can connect correctly. That is indicated in the bottom right of the program once you hit the connect button. These values should be changeable.

ok i just fixed it. I had to upload non default firmware. Thank you

Don’t upland 5.3 to your vesc

Can you show a picture of the firmware Menü?

I think it is to late, he will have the latest firmware on his VESC

Hi, Just wondering Why Not?

I never got it running properly on my setup (yes phase filter off)

Motor detection made already strange noise

(FESC75200 Flopsky + 120kv)

so I uploaded the latest firmware and everything is OK, I’ll try it on the water tomorrow.

I updated my 75200 to the latest firmware, followed efoil Hollands Manual and it worked right away. Had one test ride and I am very happy.

I found in this forum instructions for downgrading the firmware. It also seems to work.

Best

Christof

Old thread but I found this tutorial by Ludwig (the guy who designed the open source 3d printable remote) very useful, so I thought I’d link it here if anyone is browsing this thread looking for info.

So I have been working on this for the last couple of days and boy oh boy is it frustrating. It seems like every time I start new I come to a different outcome despite using the same things and settings. I think I’ve read just about each post on here as well as all the flipsky videos and website troubleshooting.

Props to Ludwig Bre’s video, solid.

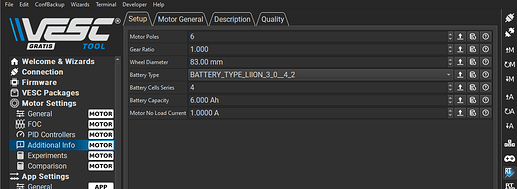

My setup is a flipsky VX3, 75200, 65161.

Where I’m currently at I am using just a lead acid battery to power up the ESC so I’m hoping that might be where my gremlins are coming from however it really shouldn’t make a difference right? It’s 12 volts with plenty of amps.

- What I’ve done so far is update the ESC to 6.0 no limits with phase filtering off.

- I’ve done the motor setup with large inrunner, direct drive.

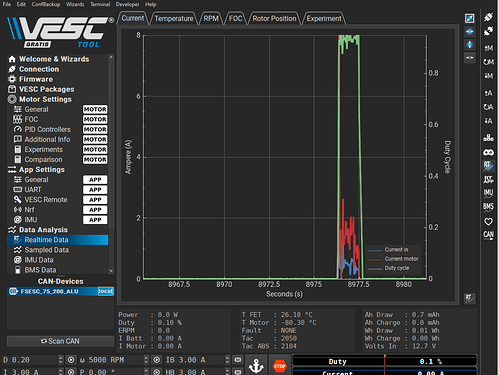

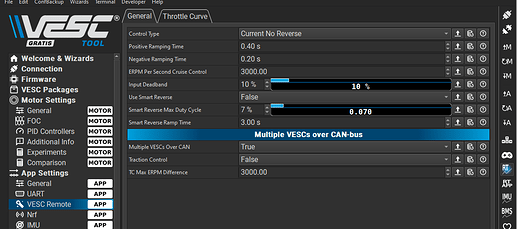

- I have tried the BLDC as well as FOC options and defici seems to be the smoother one and both of them seem to ramp up to 100% duty cycle despite being on the duty cycle option versus current control option +/- no break.

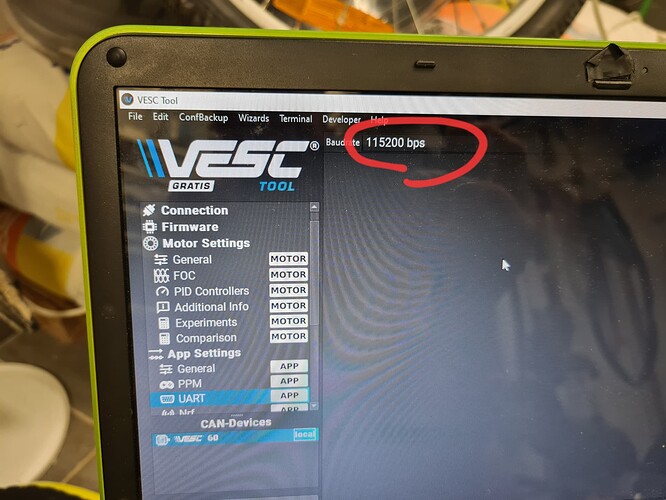

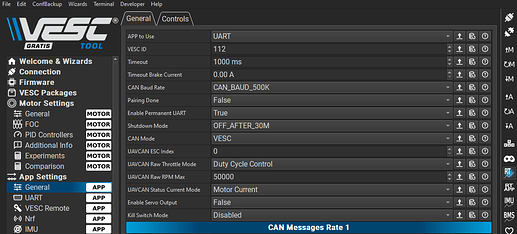

- I’m on UART as I’m not using the PPM pigtail from the transmitter / receiver.

- FESC option on VX3

- messed with throttle curves, ie 40% expo

- on BLDC I can’t get it run detection.

I have tried this in the air, in a bucket without a prop as well as in the bathtub with a prop and with real-time data I don’t pull more than 3 amps with all three of these options.

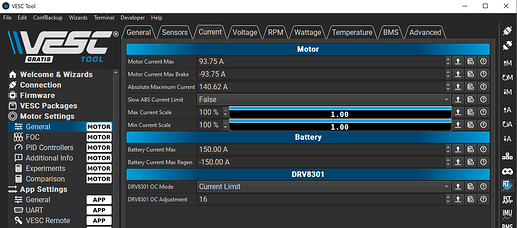

I have mirrored all the amperage options under the motor tab from other users on here.

Again, hate to chalk this up to battery but it very may well be, but with the amperage that is needed with no load seems unlikely.

So my questions are

- do my settings look fine?

- is using UART as simple as it seems and you don’t have to go through a setup like you do PPM?

- will things drastically change once I put it in the water with me on top of it compared to in a bathtub with the propeller?

- Why am I not able to feather the throttle at all and it’s spikes straight to 95% duty, even in the bath with the prop

So what exactly is your question? Without load everything may look a little awkward, but it doesn’t sound too bad. I had big troubles last year until I checked the motor cables, the connections indeed were broken. Be sure to check this. And I would use a decent power supply, something that at least simulates the real battery you will be using.

Where were the connections broken, at the coils or the bullets? For testing I’m just using crappy pigtails and not bullets yet but again for the amperage that I am suspecting at this point I can’t imagine it’s going to make too much of a difference. I could be very wrong though.

I have thought about buying a laboratory power supply for this as well as other things but typically they only put out 5 to 10 amps it seems.

I’m still waiting on the cells to build the battery so I might keep chugging along and hopefully once that’s done things just iron themselves out.

I updated the post with better questions hah

Well, with that little voltage like 12V you will likely not get many RPM on the motor (max motor RPM is KV of your motor * voltage applied)

So even with prop in bathtub you RPM is probably so low that the motor just wont pull more than 8A… Feathering the throttle also does not work with such light loads… If you imagine your throttle can control from 0 pressed to 100% presses between 0 and 90A. So if you want to control in the range of a few amps, the resolution is just not there. You can check that by setting the Motor Current Max to e.g. 10A, then try again.

Tip: Dont try with a lab supply, thats usually best way to kill a VESC  Wait for the real battery.

Wait for the real battery.

Also note you are using the 75200 out of spec! Flipsky states “Voltage: 14-84V (safe for 4-20S)”

I’ve got an old 75200 that will only run properly in BLDC mode. In FOC mode at about 3000/ 50amps it cuts out out abruptly, like it’s hit the abs_current limit ( but this is set at 300amps)

I’ve experimented with increasing current limits etc, upgraded, down grade firmware etc.

Phase filters are off.

Could this be a hardware fault on the 75200?

The VX3 display will show you how it’s connected

RP is PPM

RU is Uart

Yeah, it’s RU but just surprised it’s that easy and you don’t have to do anything specific to set it up like PPM.