I discovered the Gastronorm standard in METRO.

I don’t think anyone here has discussed this yet.

Food containers are used by many to temporarily house electrical equipment.

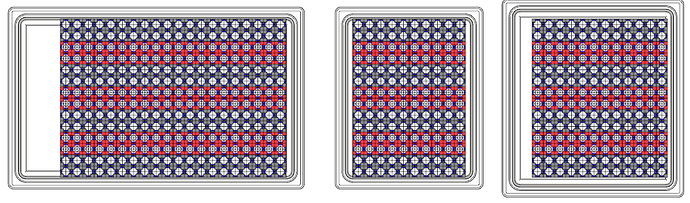

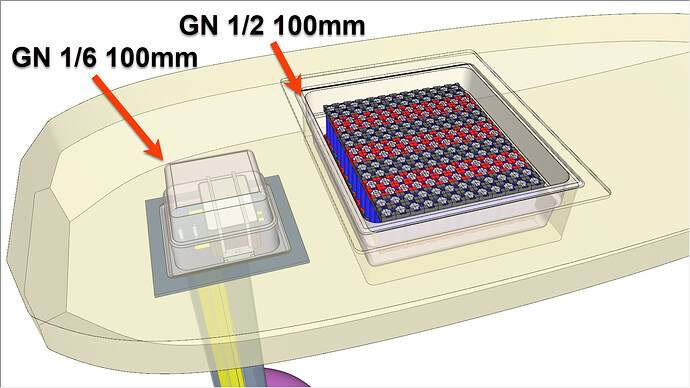

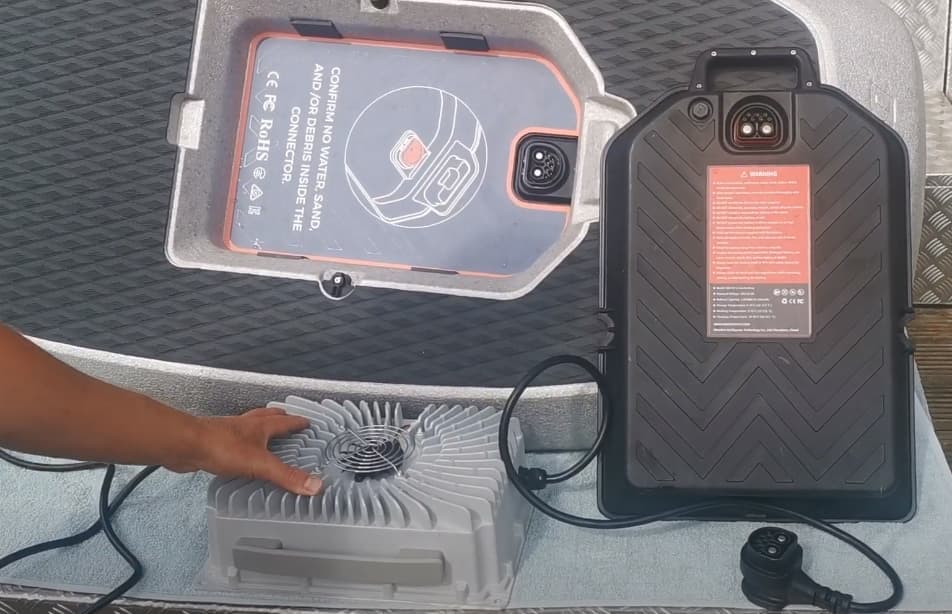

But Gastronorm standard containers, it seems to me, are a good fit for organizing a sealed compartment for the battery and for the ESC.

There are plastic containers with a sealed lid and open ones with a flat side. They can be used as an embedded part in the manufacture of boards.

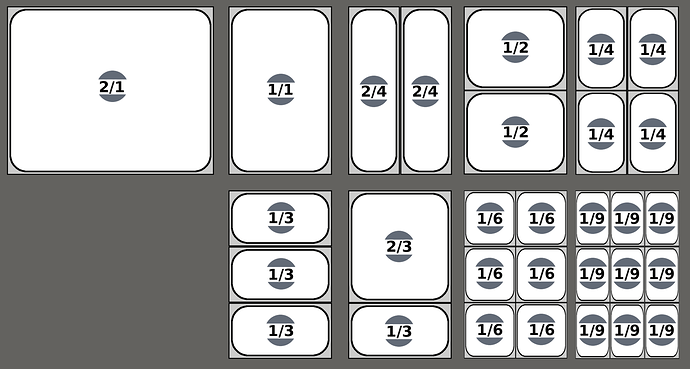

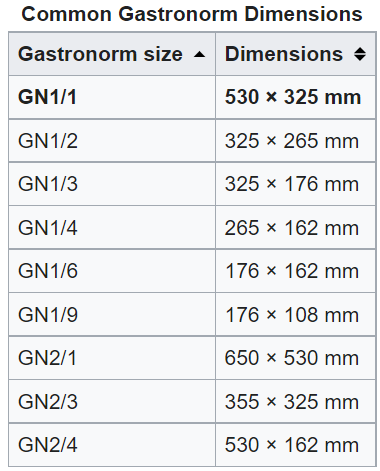

Common Gastronorm Dimensions

The dimensions in the table are the maximum overall dimensions.

Containers usually come in standard depths of 20 mm, 40 mm, 65 mm, 100 mm, 150 mm, 200 mm.

What do you think about this?

I like it! in particular the stainless steel option. should be good for the DIYer,

How are you envisioning sealing the lid?,

Remembering spending a huge amount of time trying to find an appropriately sized container- eventually ending up vacuum molding an abs enclosure.

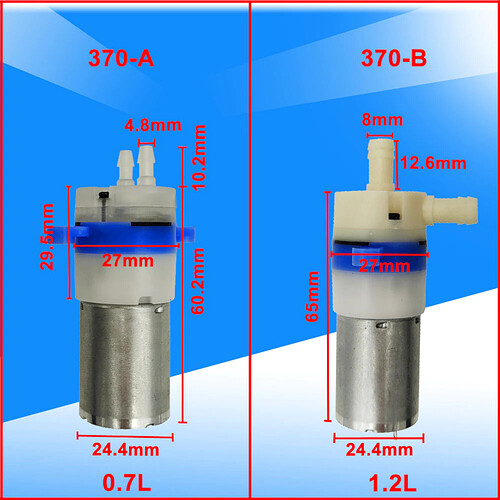

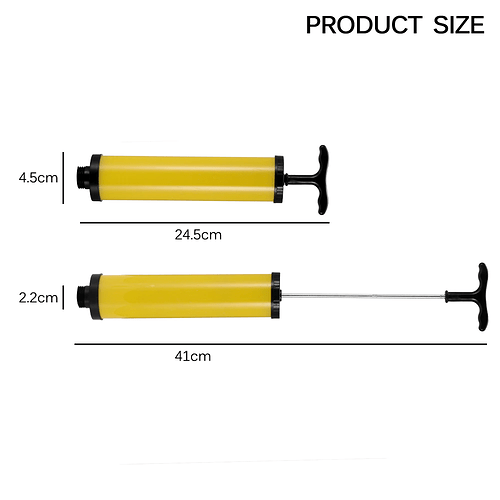

We could try creating a vacuum inside the container with a small pump.

And this cover itself can be attached to an external plywood hatch.

or

Plus bolts or locks on the outer plywood cover for security.

If you have vaccum, the smallest leak will result in sucking water into the box. Overpressure would be more useful.

I agree with you. I also like the overpressure idea better.

But it will be more difficult to achieve tightness. It will be necessary to press the compartment cover with an external hatch with force.

It seems to me that it will be technologically easier to organize a vacuum seal than with excess pressure. And it will work well.

The difference between the usage of the container for food storage and efoil compartment is that you need no holes for cables in the contaier to store food. Very likely that you get water ingress through those holes when putting the box under a vacuum.

Even if you don’t use a vacuum, these lids already have a very well sealed seal. And as a ready-made solution for installation in a board, it looks very good.

There are easier ways to build a completely sealed custom container that can also be properly bonded…

Neither vacuum nor overpressure have any benefit if there’s a leak. Both will just equalise and then let water in…

Remind us of these methods, please.

There are a couple…

1: Using carbon sheet with carbon 90deg angles to bond sheets together. This gives an easy , solid option customisable to any size.

2: Same method as above but using G10/FR4 plate. This has the added benefit that it is flame retardant as well. It will just be a bit heavier than carbon though.

3: Fuse 4x 10mm thick perspex sheets together to form a rectangle of the correct height. Carefully drill pilot holes into top and bottom. Then either tap or use self tapping screws to add a top and bottom sheet (with seal). Can be aluminium, carbon or G10 sheet.

4: This is a new method I am testing and if it works I will sell customised battery cases. Therefore I am not going to divulge anything on it yet. But if it works it should be very strong and fast to make the housings…

Methods 1 and 2 can both be bonded into a board for a less messy approach to a hatch in the board as well.

Cause it provides less flexibility…

Like waydoo … because you need to get to hatch lock and the battery plugs included in the volume and watertight, no easy to diy ( more angles …)