Waydoo put up a new statement, still claiming the battery was not the cause of the fire. No acknowledgement of the pathetically shoddy battery design or other major issues like runaway boards. Seems they are only interested in doing minimum damage control.

I’m waiting for The investigators that are spending actual time on the remains of the fire. The fire department spent 1-2 hours and went off my belief it was the waydoo battery.

The independent national investigators spent 4 hours on the day of the fire and two

More 8 hour days digging through charred remains.

The fire department didn’t even say I was home when the fire broke out after I spoke with them at the scene and told them what happened and that I was inside.

I have ordered a flite board. I have no reason to protect waydoo. I just don’t appreciate the local news and fire department not getting the facts right.

Can a bag itself stop a very large electric board battery pack fire. They are very large packs and would exceed 500 degrees when thermal runaway.

Also could a aluminium case be sufficient? I would imagine a stainless steel case at least would be needed. Aluminum would melt.

Any videos of testing these bags on a battery pack?

Looks like a nice case. Is it Aluminium? Any videos of this case being tested with a large electric foil battery pack going up in flames?

Anyone know what cells are used in the Waydoo? China made cells, or Japanese or Korean? There still is a huge difference in cell performance, safety and price between manufacturing countries.

Hi Merten,

Our team saw your comments here and discussed internally with our tech team to clarify any misunderstanding here.

We all know safety is always a very concerning topic, so we make careful design and also product testing before shipping the units to our customers. After David’s fire incident, we all feel sad about this but also skeptical of Waydoo possibly being one of the causes. Our support team has been in close contact with David, and waited for the final fire report. Any information beyond that would be misleading. Meanwhile, our team did confirm with our supplier and checked the batches we shipped to be free of any safety problem.

In terms of the points you carefully marked out about the battery design, please see our tech team’s feedback below. We welcome any discussion.

¬¬

-

In response to the slight deformation of the rubber ring pointed out in the picture, we have strict waterproof test standards during the production process, and we have conducted in-depth reviews and verifications for this possible assembly problem. We have also done many tests. These are enough tests to support us in thinking that the waterproof function of the product after this slight deformation is completely qualified and there will be no problems.

-

Our batteries are not placed inside the board randomly. The battery is fixed by the internal support structure of the case. Therefore the battery panel will not shake. The outer cover of the battery is fixed with high-temperature double-sided adhesive. In addition, when the bottom case is closed, the supportive structure around the cavity inside the box also completely restricts the battery cell, so don’t worry about if our battery will move inside. The battery also passed the drop test required by UN38.8 transportation.

-

This yellow plug, we only use it to connect the negative pole of the battery. This is to avoid the wrong connection of the power supply caused by the improper operation of the operator during the production process. It is equivalent to a mechanism to prevent incorrect insertion. In addition, it is on the same negative wire, this plug is equivalent to two heads in parallel, and the actual maximum current through is twice the nominal current.

-

The connector selected for the battery balance head is with a bayonet. After our comprehensive test, the strength of use is fully sufficient for the needs of use.

-

We have strict waterproof tests on all the buttons before they leave the factory, and they all meet the design waterproof standards, and we also have waterproof tests before they are installed on the battery case, and we will only use them if they are confirmed to be correct.

-

We have coated three-proof paint on the BMS board. The waterproof design is also mentioned above. Our shell is well sealed and reliable. We will strictly follow the product standards for waterproof testing before leaving the factory.

In addition; in response to customer feedback that the battery got water flowing outside after use, the apron is designed to be waterproof inside, so water might stuck in between. Our design meets IP67 waterproof standard, which means in the environment of 1 meter underwater, it can prevent water running in for at least one hour.

Thanks,

Waydoo Team

@LewisZhu-Waydoo

Glad to see you guys are here!

Do you mean UN 38.3? There is no such a thing as UN 38.8. ( which I doubt that connector and bms can pass all chapters requirements) what sections has met and passed? Can you share the certification please? I am wondering how are you guys shipping in the US without UL 33 which all carriers require this unless people never tell the carriers there is 2kwh battery in the box and putting people’s life in danger!

Plus I am wondering how you guys ship in Europe without CE.

Plus IP67? Which I doubt if this pack even can pass ip67 certification but Are you kidding us? Ip67 and 8 are only waterproof for certian period of time for max 1meter or slightly more without water jet. What about water jet when board can dive in to water while riding at 25kmph? No doubt why people house goes on fire from your respond it is clear you guys have no idea what are you dealing with!

Rather than playing blame game I suggest you guys to do the recall on all packs before putting more people’s life in danger! Just get find a good US based regulatory consulting company and re design the pack! There are lots of places you can cut corners to save but don’t do it with battery pack otherwise you will lose EU and. US market faster than you can imagine!

You guys have a great concept and had a great moment just don’t ruin it

Hello Everyone,

I’m looking at the teardown images and wondering?

- what the other half looks like? Merten, can you add pictures of the other side of the case?

- I wonder if there is a vent? Are there any test ‘features’?

- What is it made of? ABS or something else? Merten, are you able to see what temperature it melts at?

- Any cooling features? Thermal materials?

- Can you take a few pictures of the BMS? Identify the manufacturer? Is it a custom Waydoo made assembly? Or is it a 3rd party one they’ve integrated?

- does it have a number of large FETs that might be an eswitch? Or does it do it’s current limiting by protocol through a connector?

- Any contactors? Fuses? Or features that might open in over discharge?

- what’s the cell pack look like? Any cooling features or protection between cells?

And the fire @ David’s house?

- Do we know more about the state of the Waydoo when the fire started? Was it charging? Charged? Or stored discharged?

- Had it just been used? How many times had it been used total?

- was it a Waydoo ONE or FLYER?

- Any pictures of the remains?

- Did the fire start in the motor pod? Or in the battery casing?

Does anyone know any more?

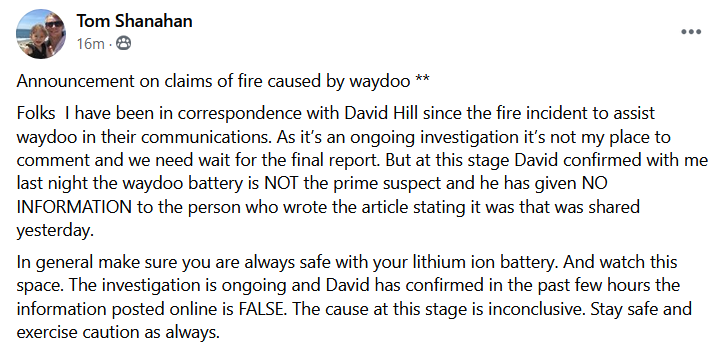

The real David Hill has been pinged many times on the Waydoo user group but he has not responded. Everyone can see that he is actively posting on Facebook over the past few weeks including multiple posts in the past 24 hours.

Maybe he signed a settlement agreement with Waydoo that included a Non-Disclosure Agreement. That’s common in these situations to avoid a long and expensive legal process.

I would say it’s more likely that he’s being very careful as there could be insurance implications.

If it was a water-damaged battery that caused the fire, an insurance company might be a little slower to pay out than if it was an undamaged product…

@FoilFiesta…

Why do you bring up another wrong assumption. Its already posted in the FB group (that you believe trustful :joy:) that information given by pacificmeister was wrong and just not true that it was the waydoo battery...... and the owner Mr. Hill points out that investigation of the insurance company is not finished!! So why should waydoo now post such thing with the name of D. Hill?? On FB group it gets clear now, that this speculation is not true, so not shure what your goal is, now?

I worked for a house insurance company and believe me if there is even the slightest heard, or the possibility of being able to pass the damage on to someone else, they will do it! Insurance companies don’t pay if they think they can hold someone else liable …

A few months ago this Lift Foil battery fire was documented in Wally Haden with a lot of documented photos… No one of you really cared about that time and now that we have no facts about that last fire nor even a photo of that waydoo battery, you are all bashing this brand down? What is your problem? Is it cheaper than your own built or is it because Liftfoil is a US brand probably building their battery in the same chinese factory?

Here some more of those lift foil battery fires…

Did pacificmeister post anything that liftfoils should stop selling and tell Liftfoil their battery is not safe? Don`t think so, but I´m shure If waydoo were an American company, they would probably have called in lawyers by now to find out your names in order to hold you liable for killing their reputation!

WOW. That’s crazy. Thought that Lift was a higher quality brand. Sounds that there’s at least two documented cases of Lift batteries catching fire while charging.

I think the point is that this is new technology and when something goes wrong it can be catastrophic, regardless of the brand.

The onus is on ALL manufacturers to ensure their products are designed and manufactured as safe as possible, but also on the owner/operator to take precautions when handling/using such large batteries.

Hopefully all of these stories will encourage us early adopters of this technology to take precautions and encourage the manufacturers to continue to improve the safety of their products.

Na it’s built by Lithos in California. It is much better quality and there are teardown photo’s in the forum as well.

You can also see Lift’s response and call to action straight away on the Facebook post

Instead of deny anything, they offered help. That’s the big difference!

Waydoo has already tried to say it wasn’t their battery and that’s what upsets people!!!

Waydoo fire:

🗸 Confirmed by fire department

🗸 Confirmed by owner

Lift fire:

Random third party with no first-hand accounts

Random third party with no first-hand accounts

I could put up a website with some fire pics and say anything caused it.

Well as far as I can read waydoo offered help to Mr. Hill as well and he confirmed that they did! He himself says it is yet not true that caused the fire! Not waydoo announced that.

That they do their statement as well is logical and Im happy that they explain their details about their battery and that they have CE and UN38.3 certification which is basic for battery safety...Actually cant find any information on Liftfoil battery if they did the UN38.3 certification. So why is the battery much worse than the Liftfoil battery? Ah yes forgot, because it`s build in Lithos…

@Foil Fiesta

Already know that you have your own war against waydoo, not clear why…actually I don`t care…

Check those photos of the burned Lift foilbatteries from inside. Not objective enough check the Wally Hayden Fire department investigation or ask Liftfoil;-) The are familiar with that case…and after that they announced to store batteries in their safe alloy boxes, you can buy with them as well:wink:

Did you see some photo proof of the case above?  Maybe start use your brain instead of shouting out loud on others.

Maybe start use your brain instead of shouting out loud on others.

Actually wasting to much of my time… I´m out now… I store my Lithium battery safe, no matter where they come from and who built it

Look at the teardown of both and try figure it out for yourself… You may gain some insight and perspective and possibly learn something…

Already did, saw some great ideas. Actually my next DIY battery will get that kind of seal and I will try integrate the new Trampa mini VESC in it and use the alloy plate as well for cooling it… So only 3 motor cables out with those Fliteboard waterproof plugs…Smart BMS inside with charge connectors switchable only if charger plugged in…

No more water proofing on conjunctions, mast box a.s.o… and could change to different mast/motors and boards…as you like…Kind of modular…

Anyone build similar setup before?