I had a waydoo battery go bad on me. The symptoms were that the charger was flashing purple or blue and the battery wouldn’t charge.

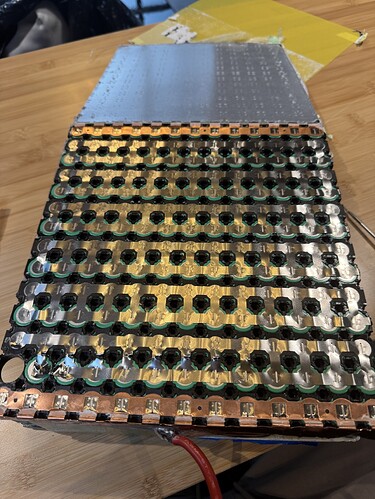

So I did the unthinkable and tore it down. The whole thing was filled with epoxy, a Process, which is called potting in the industry. Manufacturers do this to protect their components both from physical damage and from intellectual theft. In other words, it was a long and difficult process taking this battery apart.

Testing the cells I found they were out of balance. That could be the problem, or it could be a consequence of something else.

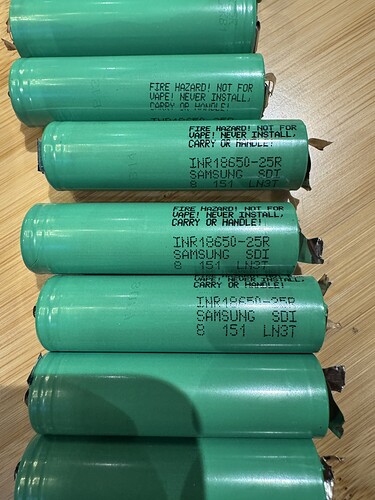

The second last row of 13 cells in parallel were showing 0v and some 5 ohms. They are clearly bad. Were they bad from the factory ? Or was the bms the problem?

Interestingly the battery has a further pcb on it (pictured) which has 100 ohm resistors on it, one for each series of cells. The resistor for the bad row was showing no continuity so I assume it’s burnt out.

2 or three of the other resistors are also showing no continuitiy.

This would mean that the bms cannot balance charge them. That could have easily led to the failed row of cells.

But why did the resistors go bad ? I’ve never seen resistors in a battery like this. Maybe they are normally on the bms.

I could replace the resistors but I am wondering if I should instead take them all out so this doesn’t happen again. I would love to hear some thoughts from someone with experience in this area.

My plan is to pop out the row of bad cells and weld in new ones and see if I can get this thing working again.