Hello, im waiting my first 6384 from china and thinking about a better Waterproofing.

i may be wrong but i read that many of u used kryptonite bearings, antocorrosion magic fluids but the total life of these bearings is still quite short. So in my opinion the issue is that sand is passing the sealing and kills the bearings.

2 options

1

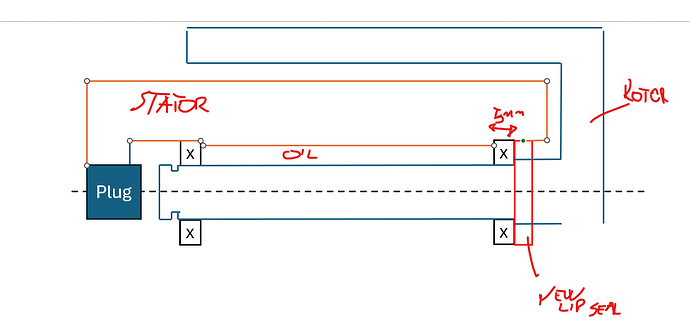

My idea is on the back remove the bearing from the stator, with the lathe make the bearing 5mm deeper to make room for a lip seal, add a lip seal on the back, than cut the shaft, fill the chamber with oil and add a plug on the front to seal the zone.

Opt 2 same as one but instead of machining the back using a double lip bearing like this: https://www.bike24.com/p2174536.html

While on front same thing cut the shaft and add a plug after filling with oil.

Finally add a sacrifical anode on both stator and rotor

Thougts? Is a dumb idea? Thanks

63xx is an outrunner with a rotating bell, I don‘t think you can make it waterproof. You will have water insde the bell around the stator. This is good for cooling because we put a lot of load on that small motors. I think it can only be made water resistant and needs some maintenance from time to time. Stainless steel bearings last about 500km on my 63100, epoxy coating can be redone.

If you want the motor waterproof and filled with oil, better chose an inrunner like 65161. It has seals already and can be filled with oil. It weights more for the same power, but needs less maintenance, especially in salt water.

In fresh water, corrosion of epoxy treated outrunners is not too bad, I run mine for the 5th season. Changed the bearings 3 times and recoated stator and rotor twice.

i got that is an outrunner, i only want to enclose the bearings under oil not the whole motor. like this:

not sure how to make the rotor pushing on the rear baring without remachining the shaft, not sure how the end of the shaft is now pushing against the bearing, is there 5mm margin for a lip seal of bigger diameter?

or simply use an ultra sealed bearing as above. as i said still waiting to have the part on my hands…

This is an interesting idea but seems to require a lot of extra work. If you have the free time and equipment go for it. I use a bearing that costs $0.80 from amazon and change it once per month. I foil in saltwater 5-8 hours per week.

Well depends, still waiting my motor to measure it and understand the effort, if it easy to remove the shaft an machine the grooves it takes 15 mins with a lathe and will be a longer lasting solution if it works. Bearings will work better and smoother if well lubricated. Just dont know if there is room for it…

Ok i have motor in my hands, hte idea could work but needed to machine the rotor while it is conic before the bearing, so i machined the rotor to be 12mm so i can put a 12x19x3 lip seal before the bearing.

Need to go tu buy the lip seal in these days and will try.

added lip seal and filled with oil, keeping on my desk and no leaks so far, just a bit complex to fill with oil but it worked. Printing other pieces and will test in water soon.