Wiill it be… 3D printed, moulded, casted , CNCed ?

3D printed composite with glass (no FDM) which holds up the forces.

The esun ePA gf is available locally, at about double the price of PLA, impact tough and produces a nice print finish. If I can design a prop I’m happy with, I’ll probably give it a try. The trick will be working out how big to make the diameter, pitch, and blade area so that the power consumption is minimized but it still has a bit of push to get into waves, and which kV of the 6374 to get.

I am building my downwind assistant with a 6374 170kV and 6S batt , I went for 130mm prop due to the lower torque. I will provide a complete set of instruction if it works…

Very interesting. I’m waiting for the results.

Wow. I think 160mm is too big for 63100. Can you log your drive?

I was using for awhile Volker’s prop 3D design 4 Loch 158 0.38 1.05 15 NEW | Tinkercad with reduced pitch for my 140kV motor. This is a folding version of it. Will see results tomorrow.

Hello

I am looking for a 3d file to make a splined propeller, because my propeller causes big vibration, I think it is not balanced and it has a centering problem, if someone made this type of propeller, I am a taker, thank you

I found the link for the hub for the propeller. Does anyone have active files for the blades? I’d like to experiment with some alternative 3d printer materials.

Also - I have access to a CNC router that’s capable of aluminum machining if we get something working I might be able to help make something.

Thanks!

Austin

Has anyone mounted this type of propeller on a 65161 toothed shaft motor because I cannot find the dimensions (drawing)

I don’t think this is a viable approach because the best propellers (for e-foils) don’t use slotted hubcaps. If I were you, this is what I would do as a first step - using a press to extrude the slotted brass sleeve. This bushing is then machined, preferably on a lathe, to have the smallest outside diameter possible. This first step will not only minimize your motor’s biggest weakness (the splined shaft) once and for all, but more importantly, it will create the ideal conditions for attaching some of the many times proven propellers.

Hi, Austin, this will be very helpful.

What kind of engine do you have available?

Tested my folding prop yesterday. Main idea to use it on flat water was to reduce drug and board “diving” when you release the trigger. I did not notice big difference between folding and regular prop. Maybe it is just me, i do not have surfing and pumping experience. @Toto44 was right 160mm size seems overloading my motor. You can see it on log(GPS did not work properly). First 12 minutes was on folding prop trying it “on and off”.

Then i put my favorite 145/0.5/0.9 Cruising speed was 20-22km/h (recorded by Garmin watch), 3950-4000 rpm, 42A.

If somebody wants to play with this folding prop here STL files. Reason i printed blades on “side” to prevent delamination around axis of rotation. Model was done on https://www.wageningen-b-series-propeller.com/ with parameters:

Diameter 160 mm

Expanded area 0.3

Pitch/Diameter 0.9

Rake 15

Hub:

Upstream D 63 mm

Downstream D 55 mm

Length 40 mm

Blade:

Root 7mm

Tip: 2mm

Leading/trailing edge fraction 0.15

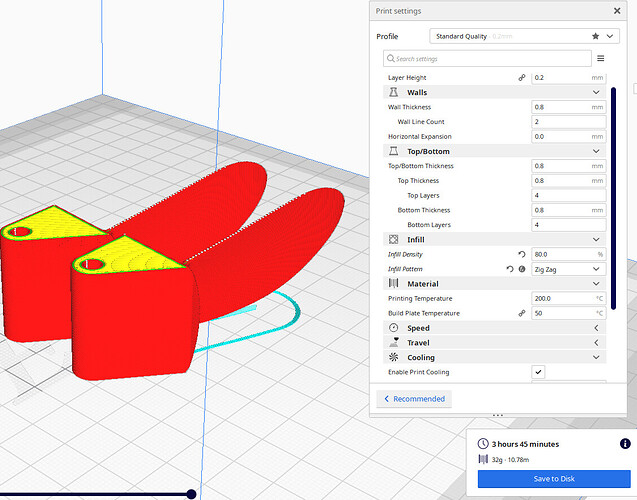

Printed with PLA+ , 80% infill, ZigZag, support > 75 degrees

Always print my props with such parameters (10-12 total). Never had broken one.

Link to STL files:

It also has a lot to do with the wings you use. You need high aspect ratio wing, they have less induced drag and will keep gliding once you power off. You also have to shift your weight on the back when you release power

I see. I suspected it. I have a Cabrinha Varial Medium wing 1300cm. It has AR=4.6 witch is not very high. I noticed it has a lot of lift, hard to hold it down on speeds higher than 20 km/h. What foil would you recommend for higher speeds?

The high aspect 10:1 wings like the Axis 999 are very power efficient and generate lift from low speeds.