I print everything horizontally. Of course, it always depends on the construction

Thanks - yeah I was assuming that would be stronger. Is that for all parts eg the mast clamps too? How do you get such a great finish… or rather, how do you do supports in a way that allows such a great finish? I am using Cura and playing around with this… but end up with really messy surface. Particularly difficult is the folding props.

The beautiful surface comes mainly from the CF content in the filament. Everything else is good slicer settings and a long 3D printing experience.

I don’t like PETG because it degrades in water and breaks down when exposed to vibration. I believe that adding unstructured carbon fibers degrades the properties of the original material. It becomes hard and brittle, the only positive thing is its appearance. In general, I don’t really trust 3D printing and would definitely prefer injection molding or aluminum milling if I had the opportunity.

Speaking of motor mounts.

Has anyone found a sweet STL for a Naish S26 or S27?

Sorry I’ve wasted dozens of hours of printing trying different models.

My Onshape skill are just at the beginner level! ![]()

TPU for clamp. PETG or ABS for back of mount. PLA or whatever for nosecone.

I broke one 2 piece clamp filled with epoxy before this and haven’t had any more issues (besides lost the nose cone because it was just press fit initially)

I ran amz3d pla for my mast clamp all last season more than 150 sessions and its still good. It appears pla if printed with good layer adhesion and not left baking in direct sun is ok. I used white to minimize heat absorbtion.

I’ve just been watching a bunch of videos of people comparing materials… looks like PLA is actually stronger than others like ABS and PETG - and some of the PLA +'s have better heat range. That said, the layer adhesion seems to be the issue so I’m not convinced youtubers do that good a test.

Talking with someone who does 3D printing for a living… they said: “Petg-cf or nylon would be my recommendation for an efoil. Tpu is very hygroscopic so not great for applications involving water. It’s definitely one of the most durable filaments and could work but may not come out nice with a complex shape that has thin walls”

I posted this earlier - but this filament guide by Bambulabs is very useful.

Interesting to see that PA6-CF is better in every aspect than any other material in their table (aside hygroscopicity and layer adhesion of TPU)

Yeah. All these years I’ve heard that PLA is just a beginners filament and no good. Quite the opposite… ofcourse as long as it’s not exposed to heat above 60C - which is useless for me here in Queensland Australia.

I have been doing some research and found a few changes to make to print settings and what a difference! I’ve just printed a folding prop blade… and I can’t break it at all (by hand at least).

I have just created a new topic to document my build - and added a post on 3D printing which details how to get the strongest prints. I will update it as I learn more.

Anyone with PETG experience? I am having issues with the walls separating under load (when bending).

I’m new to PETG. Got PETG Cura profile from FilamentFriday which produces lovely looking prints on my stock Ender 3 v2 - but when I print the props with 7 walls and 60% infill - when I try to bend/break the prop, the walls split, then the layers split. I have tried a few temps (225 and 240) same results. It’s a new roll, so, hopefully shouldn’t have moisture.

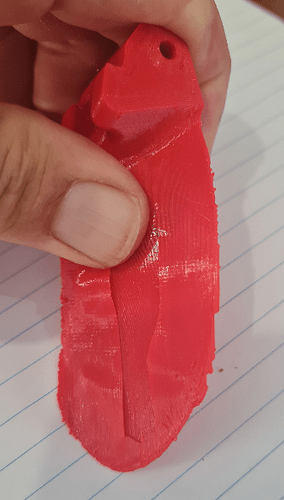

Here’s a pic of when I push down on it…

When I print the same thing using PLA also with 7 layers and 60% infill I cannot bend, let along break it.

Interestingly, the infill looks super solid - just the walls arent sticking together well.

Have printed some 50x10x3mm strips for quick testing - they don’t separate when bending - but I can split the walls with a knife - which I dont think should be possible.

Print without fans.

Why you don’t print solid propeller?

I plan printing propeller using PC. PETG seems too me too flexible.

Thanks. Walls provide more strength than infill - provided they run along the axis you need strength. Also walls protect better against water ingress.

I haven’t tried PC - while it’s strength looks good on paper, I’m not sure about how it goes in water. Also it requires a higher temp than my Ender 3 can do and also requires a print enclosure, and sounds like a right pain to print with. Would love to hear how you get on with it. I’m struggling enough with PETG but from all accounts (and data) sounds like what I should be using.

Once I’m happy with this I will print final items in PETG-CF.

I also have an old UV resin printer… so will try that as just discovered some “Tough Resin” (and looks like AnyCubic have significantly increased their strong resin range) - the old standard UV resin was very brittle - ok for prototypes only.

Have tried rotating the part 90 degrees - so concave face of prop facing up. Also tried with slower print speed (35/17.5mm/s) - not much better - walls still split out when under load (when I bend it).

Will give up on PETG for now. I find it’s great on solid parts - just not this prop blade - maybe it doesnt like thin compound curves. I suspect its part due to the slicer not doing a great job or poor quality PETG.

Try drying your petg. Maybe also try increasing the flow by 10%. It should be much better than this. I have not used a printed prop yet but the ones I hjave printed to see seem quite strong. Ender3 neo.

Thanks @windego, will try this.

I just tried a test print with another filament- PETG-CF with a new hardened steel nozzle (0.4mm) and similar on the 50x10x3mm test rectangle with 7 walls… they looked great and well adhered but I could split them with a blade. What I dont know is if this is normal and am I asking too much ?

Brilliant - that solved it (increasing flow from 95% to 105%)! Thank you so much @windego - that has had me stumped for a long time!

Have tested on PETG and PETG-CF.

Now trying changing speed back up to 50/25mm/s from a suggested 35/17.5mm/s.

Glad that helped. Enjoy

Bumped the speed back up to 50/25mm/s and it looks the same and same strength. Happy with that.

The only issue (with both PETG and PETG-CF) is the very thin parts still split at the extremities… PETG-CF on left and PETG middle (red) and PLA right (grey) - note I was able to break the top and bottom edges of PETG-CF more then one edge of PETG and not at all on the PLA. To be fair I had to really strain very hard to break these - they all exceeded what I thought a 3D printer could produce.

The PETG-CF is certainly a lot stiffer than PETG. PLA nearly as stiff as the PET-CF but stronger and the PETGs flex makes it more forgiving.

Might have to try even higher flow rate. Or just use PLA or could try annealing maybe (as there seems to be some weakness in layer joins still).

Increased flow rate to 115% and its even stronger. Tried slowing down to 25/12.5mm/s but little difference so bumped back up to 50/25mm/s.

Also tried a bit cooler (I’ve read the Ender 3’s dont like running 230C or more) - but I think this was a touch weaker - so leaving at 230.