where do you buy that length of stainless steel screws?

my friend did his last clamp in resin with a resin printer, and it is turning great. so far it seems very tight and sturdy. quite heavy though

I get 1m stainless steel threaded rods (available in most of the hardware stores here), cut it at the desired length and glue on a nut at the end with either loctite 638 or whatever epoxy i have at hand.

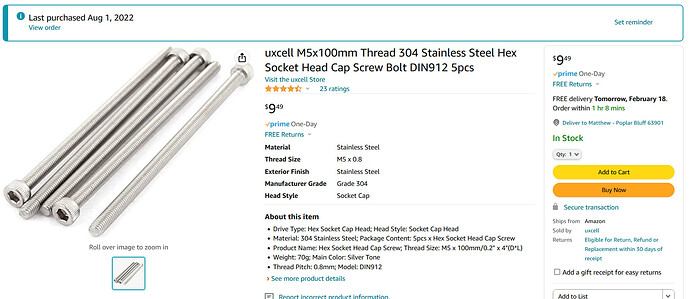

I buy stainless metric bolts on amazon, they have a surprising selection, and I actually got them in 2 days!

There are different types of stainless steel (SS): the 304 (or A2 SS for interior use) is cheaper but rusts in salt water, 316 (or A4 SS for outside use) doesn’t…

I am surpised there is no mention of ABS… does no one print using ABS as surely it is stronger than PLA, TPU and PETG?

Looking for advice - opinion on does anyone replace their 3D printed motor mount each season even if it shows no sign of cracking or wear as a preventative maintenance best practice?

I print with PETG, and never had issues.

No reinforcement.

Certain properties are better in abs but others worse.

From my little experiments 3d printing with petg and PC, I recommend printing with no fan, other than bridge (or probably support). It is day and night regarding layer adhesion and thus part strength.

And I liked petg for being flexible instead of breaking fast when bending.

Thats an amazing finish- how did you achieve that? What printer settings do you use? Nozzle & bed temp, speed and retraction? Also what printer? I have a Creality Ender 3 - wondering if the stock nozzle can work with this material.

Nice… ok sounds out of my league. Will take a look at the Bambu printers. Have just ordered a new nozzle that can handle the CF and ordered some PETG-CF. Just doing initial test prints in PLA to test fitting it all together.

The main thing I wanted to know was infill - are you using 100%? or somehow adding epoxy etc?

Thanks.

No Epoxy. 7 walls and 60% Infill

No Epoxy. 6 walls and 66% Infill

Thanks.

Which direction/orientation do you print objects to get the most strength? I read on the forum to print the propeller blades horizontally. Wondering about the motor mount and mast clamp too?

I print everything horizontally. Of course, it always depends on the construction

Thanks - yeah I was assuming that would be stronger. Is that for all parts eg the mast clamps too? How do you get such a great finish… or rather, how do you do supports in a way that allows such a great finish? I am using Cura and playing around with this… but end up with really messy surface. Particularly difficult is the folding props.

The beautiful surface comes mainly from the CF content in the filament. Everything else is good slicer settings and a long 3D printing experience.

I don’t like PETG because it degrades in water and breaks down when exposed to vibration. I believe that adding unstructured carbon fibers degrades the properties of the original material. It becomes hard and brittle, the only positive thing is its appearance. In general, I don’t really trust 3D printing and would definitely prefer injection molding or aluminum milling if I had the opportunity.