Yes, of course I can share the MastBase with you. I’ll write you a message.

Oh great, thank you… i was going to draft one up but youve incorporated some good ideas in there… i might get another mast (they’re really inexpensive in tbe UK) and redo what ive already done !

K.

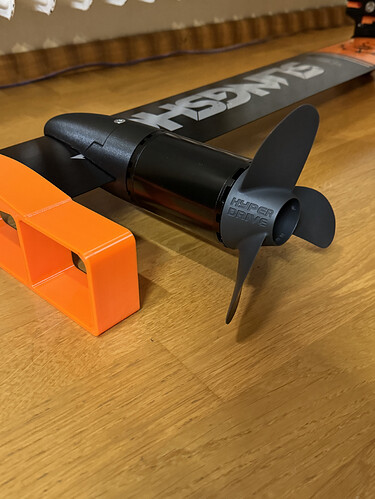

In the last few days I’ve been thinking about how best to transport my mast in a motorhome or car.

I quickly constructed a spacer so that I could lay the mast flat and protect the propeller and motor.

Very impressive work!

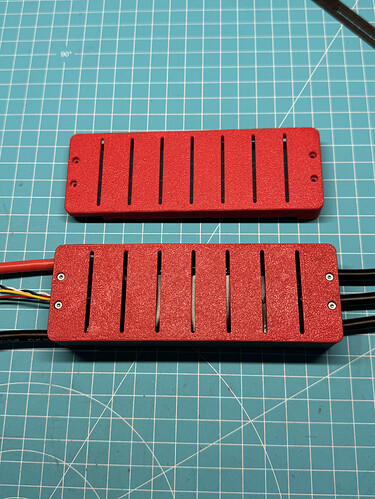

The quality of your print results is really nice.

Can you share some of the details on your setup?

Printer type and model

Slicer program

Filament brand

Thanks so much.

Oh, that’s going to be difficult.

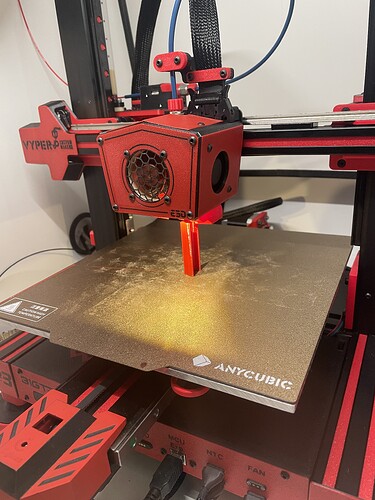

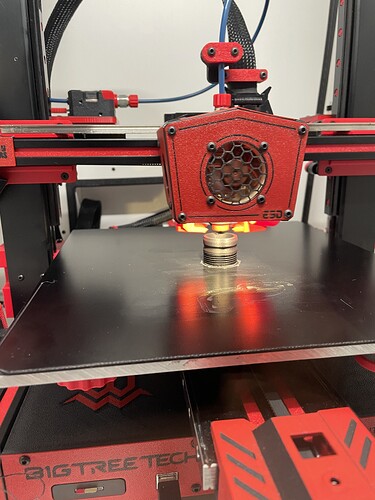

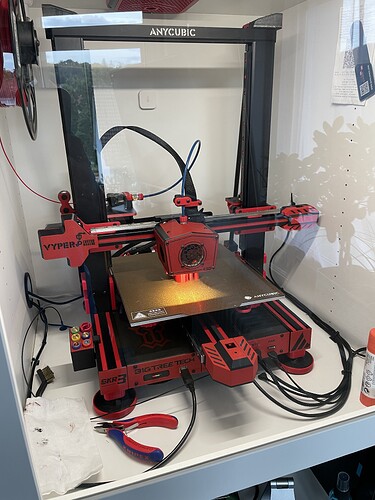

I have a fully modded Anycubic Vyper.

The mods on the printer alone took over 1.5 years. Only the frame on my printer is original ![]()

Different motherboard and Klipper make the subtle difference with good components.

This includes my 7 years of experience in 3D printing. If I were to buy a printer now it would be a Bambu.

It can keep up with mine in terms of quality.

But I just have too much fun constructing and tinkering and screwing.

Slicer: Cura

Filament: Smartfill ASA Red Ruby 250°C

Enclosure 45°C

PETG-CF ![]()

They are indeed very nice prints! Making FDM look like a resin print. One reason I enjoy @hangloose updates is seeing the excellent prints. 3D printing is a deep rabbit role with so many parameters and details to tweak. It can be an entire hobby unto itself but I think for most of us this forum it’s just a means to an end. We are having a chance here to see what happens when someone takes the time to really dial in the settings for a filament on a good printer. Keep up the good work @hangloose!

I purchased a new printer the other day. It was between the Bambu and Creality K1 Max. In the end I went the K1 Max route and I needed the extra size and didn’t need multi-colour.

I can tell you once dialled in it is freaking insane! It can keep up with the Bambu WRT both speed and quality for less money. Prints that used to take me 10-12hrs now take me 3-4hrs.

I don’t care about how long a print takes. Better a little slower and top layer adhesion or quality.

I fully understand the difference between Creality and Bambu when I contact support. I have two printers: Ender 5 S1 and X1C. Ender worked for a couple of months, after which all sorts of breakdowns began to haunt me. For the past six months I have been communicating with Creality support service, whose representatives have been playing the role of good and bad cop all this time. The good cop promises to send the parts. A week later, an email arrives from the bad cop, in which he once again asks to do 10 tests, shoot five videos, and promises to eventually give recommendations for self-repair. All these six months the X1C has been working smoothly, sometimes I just lubricate its screw racks.

I apologize for the hyjack of your build thread.

I will create a new topic on 3D printer and hopefully the conversation will move there as it is quite interesting.

buy cheap buy twice or better

The bitterness of poor quality remains long after the sweetness of low price is forgotten

No sure why this is directed at me… My prints on the K1 Max are production quality…

give it some month

20 char

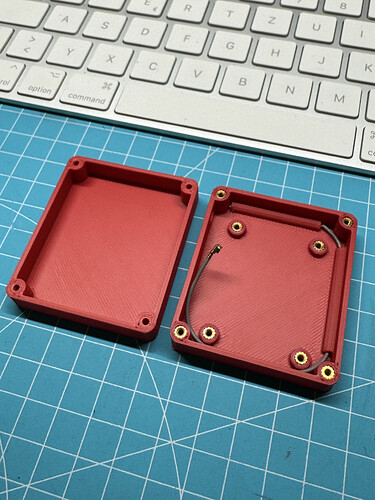

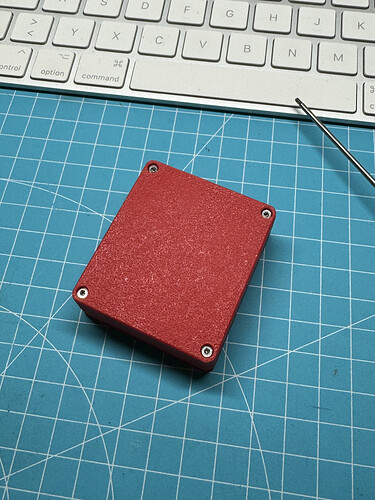

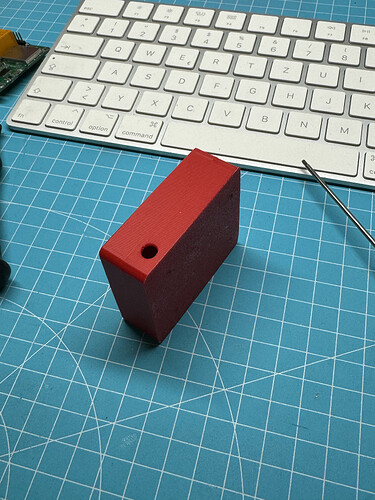

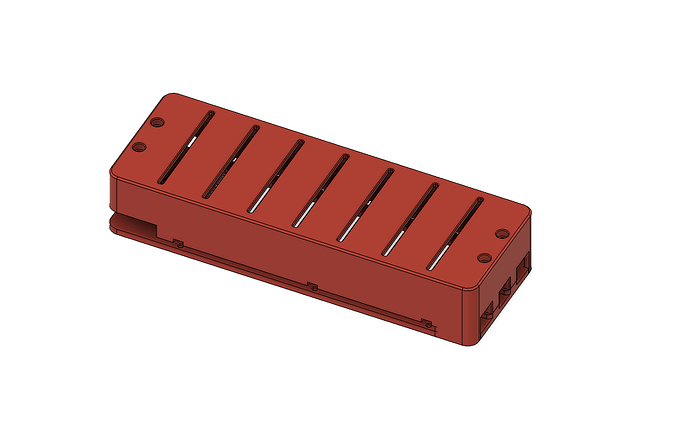

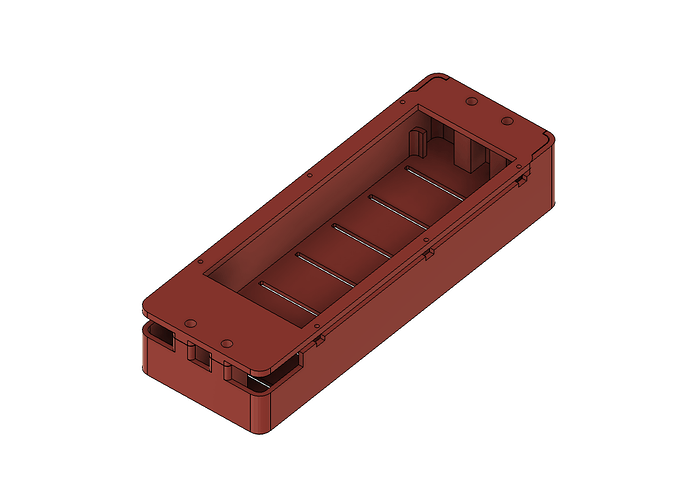

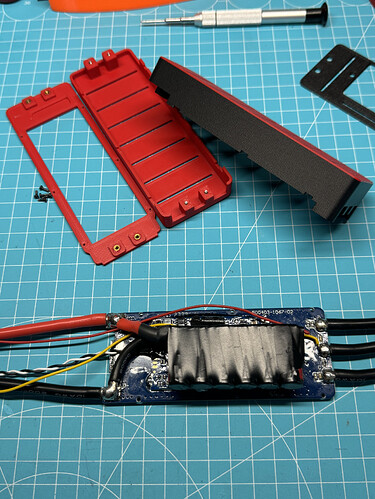

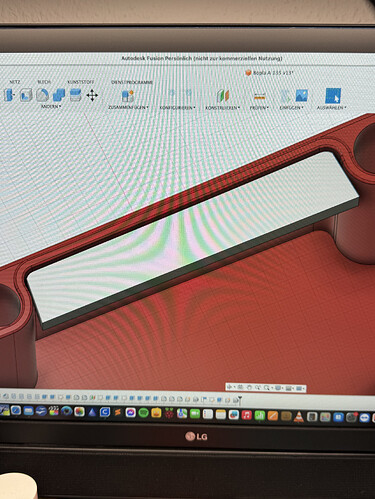

Anyone who knows my posts knows that I am never satisfied with anything and am constantly optimizing my creations. Since I preferred to have the capacitor bank with the ESC, I changed the height of my ESC cover so that the bank is integrated.

Red Filament: Smartfill ASA Red Ruby

Black Filament: Extrudr ASA-CF

Next steps, the aluminum block is attached and adjusted for the gap.

Could i ask you to check what the stator width is on the saite 63100? The freerchobby 63100 i got is 74mm, stator width seem to vary a bit on the different seller’s motors.

Why did you decide on the 63100 instead of a 6384?

I think you mean stator length?

Since I operate the Proneboard as a pure eFoil in Germany, I was looking for a more powerful motor like the 6384.

That’s why it became the 63100.

In addition, the processing and concentricity of the Saite motor is significantly better than the 6384.

It’s difficult for me to measure the stator length because my MotorPod is completely completed!

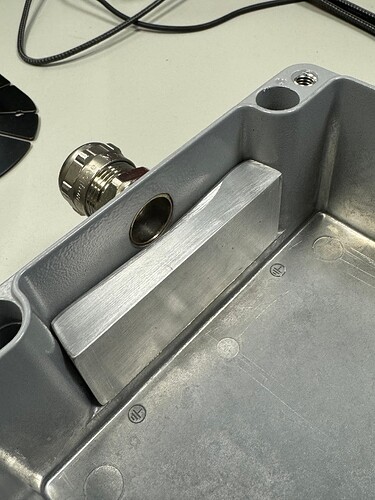

Unfortunately, since I don’t have access to a milling machine, I had to sand the aluminum block to size using a chop saw and a belt sander.

I like to use 3D printing stencils for customization.

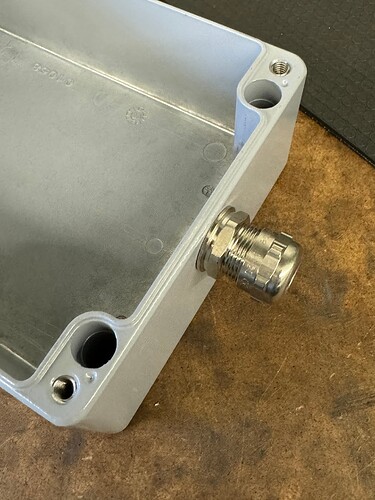

I used stainless steel helicoils in the Bopla box.

In the long run, this is simply a better screw connection than screwing directly into aluminum.

Since @tosh.jah is currently doing a similar project with a ProneBoard, we exchange ideas every day.

That’s why I love this forum!

THX @tosh.jah for the Alu Block and your ideas

Take a look at either Sherline or Taig mills. They are compact but can cut Aluminium very accurately. I bought a used Sherline when I started all my DIY efoils and its been a massive help with all my projects.