Print without fans.

Why you don’t print solid propeller?

I plan printing propeller using PC. PETG seems too me too flexible.

Thanks. Walls provide more strength than infill - provided they run along the axis you need strength. Also walls protect better against water ingress.

I haven’t tried PC - while it’s strength looks good on paper, I’m not sure about how it goes in water. Also it requires a higher temp than my Ender 3 can do and also requires a print enclosure, and sounds like a right pain to print with. Would love to hear how you get on with it. I’m struggling enough with PETG but from all accounts (and data) sounds like what I should be using.

Once I’m happy with this I will print final items in PETG-CF.

I also have an old UV resin printer… so will try that as just discovered some “Tough Resin” (and looks like AnyCubic have significantly increased their strong resin range) - the old standard UV resin was very brittle - ok for prototypes only.

Have tried rotating the part 90 degrees - so concave face of prop facing up. Also tried with slower print speed (35/17.5mm/s) - not much better - walls still split out when under load (when I bend it).

Will give up on PETG for now. I find it’s great on solid parts - just not this prop blade - maybe it doesnt like thin compound curves. I suspect its part due to the slicer not doing a great job or poor quality PETG.

Try drying your petg. Maybe also try increasing the flow by 10%. It should be much better than this. I have not used a printed prop yet but the ones I hjave printed to see seem quite strong. Ender3 neo.

Thanks @windego, will try this.

I just tried a test print with another filament- PETG-CF with a new hardened steel nozzle (0.4mm) and similar on the 50x10x3mm test rectangle with 7 walls… they looked great and well adhered but I could split them with a blade. What I dont know is if this is normal and am I asking too much ?

Brilliant - that solved it (increasing flow from 95% to 105%)! Thank you so much @windego - that has had me stumped for a long time!

Have tested on PETG and PETG-CF.

Now trying changing speed back up to 50/25mm/s from a suggested 35/17.5mm/s.

Glad that helped. Enjoy

Bumped the speed back up to 50/25mm/s and it looks the same and same strength. Happy with that.

The only issue (with both PETG and PETG-CF) is the very thin parts still split at the extremities… PETG-CF on left and PETG middle (red) and PLA right (grey) - note I was able to break the top and bottom edges of PETG-CF more then one edge of PETG and not at all on the PLA. To be fair I had to really strain very hard to break these - they all exceeded what I thought a 3D printer could produce.

The PETG-CF is certainly a lot stiffer than PETG. PLA nearly as stiff as the PET-CF but stronger and the PETGs flex makes it more forgiving.

Might have to try even higher flow rate. Or just use PLA or could try annealing maybe (as there seems to be some weakness in layer joins still).

Increased flow rate to 115% and its even stronger. Tried slowing down to 25/12.5mm/s but little difference so bumped back up to 50/25mm/s.

Also tried a bit cooler (I’ve read the Ender 3’s dont like running 230C or more) - but I think this was a touch weaker - so leaving at 230.

Can anyone recommend:

- a seal, like a rubber ring or gasket, for a rectangle hatch cover

- a sealant product to seal holes through 3D printed parts eg for phase and battery wires ?

I am thinking of putting the ESC and RX in the motor pod (attached to the mast), and having a hatch on each side (one for ESC one for RX) with a cover screwed on.

This is for use on PETG-CF 3D printed parts.

Where did you get the stl for the slingshot mount. I have PETG CF and a Bamboo printer.

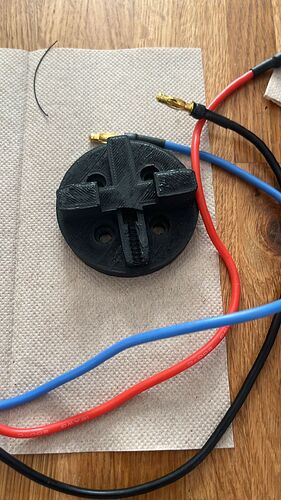

It’s my own Design:

Does anyone have a file for this motor mount? It’s for an older 6384 mount, and has the 4 screws from the side to attach to the mast mount

I probably have this file saved. Send me your email address and I will share it with you.

New material - PEBA. An alternative to TPU. It got many great properties, including withstanding cold temperatures @Bzhwindtalker.

Several yt videos popped out.

I also recently saw this

May be interesting - strong and may even dampen vibrations and sound from motor

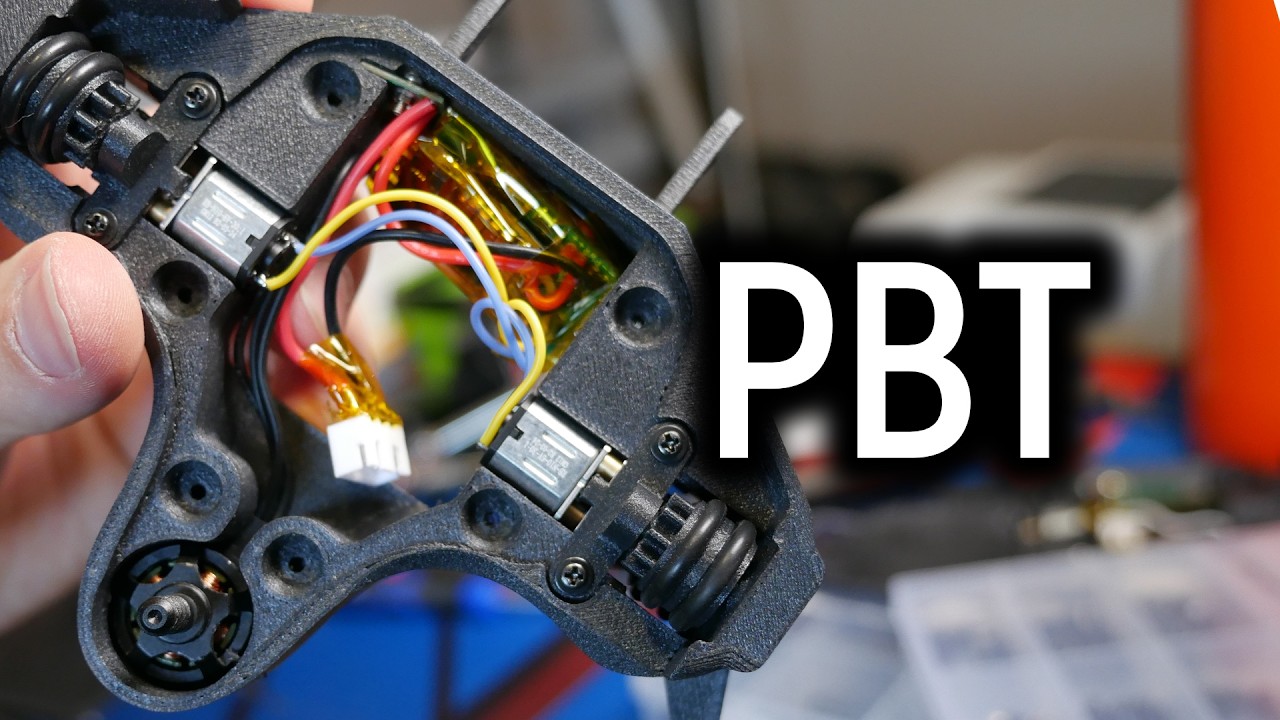

I recommended PBT before for low temperature and more. And I tried the PBT-CF version…

It is strong - hard to break and only a little flexible, good for small parts, but for large parts there is a great wrapping problem. I guess that PEBA will not have wrapping problem, as it is similar to TPU.

But is it strong enough to hold a motor without flexing too much?

Ye, PEBA/TPU is best suited for the internal part of nano pod for example.

But I did experiments with full tpu mounts and it appears to be possible to have enough rigidity if the mount is big enough. For example it may be an interesting experiment to convert nano pod to fully TPU.

Has anyone done an assist pod for 6384 for Armstrong mast A+ with wires to run internally I’m going to drill out run wires through mast for cleaner assist?