The connectors are the standard issue gold plated bullet connectors. I had them each in their own “waterproof” cover made from modified “glands” and that worked pretty well, but I saw a small amount of moisture in one of them after a session so I thought the same as you, and I got rid of the covers and just covered the joints with waterproof heat shrink which I think is actually keeping them dry. I also tried tieing the connector bundle you see up higher to the box to keep them out of the water and it seemed to make no difference. That led me to think the problem is with the motor. And seeing the “short” (very low resistance) from motor wire to the motor shaft seems like confirmation. Interestingly the motor wires are “open circuit” to the motor case and mast and fuselage. So I suspect some winding in the motor is somehow contacting the rotor. This should not happen but I have had other issues with these “waterproof” motors on my outboard engine electric conversion using most of the same parts. What the path of current is, from my hands in the water on the board back to, is unclear to me. Here is a photo of my disassembled Maytech equivalent motor from 2 years ago, where some windings seem to have burned out. Anyone have a good way of repairing this? Seems like I will need to open the Fliupsky motor on the efoil to inspect.

For safety purposes and to be able to get back on the water soon, I should probably replace this motor quickly and the fastest would seem to be to purchase it on Amazon at the Flipsky listing, for $345 with free shipping, 2 day delivery, basically the same price as ordering from the Flipsky.net site with $50 shipping from china. I see that an aftermarket warranty is also offered by Asurion when purchasing the motor on Amazon, for $39 for 3 years. I almost never buy extended warranties, but in this case that is very tempting. Has anyone here tried/used the Asurion warranty on a Flipsky device with success? The fine print does not seem to exclude our use cases and the Amazon site was willing to put it into my shopping cart with the motor. I have not seen any good deals on the motor elsewhere, not on Ebay or Foil.zone or FB marketplace or Craigslist. The motor I am using that now seems to have the “short” I did purchase from a foil.zone user in the past year, in a package with some ESCs. It seemed to be new in box but who knows. And from now on I will check all fresh motors for conductivity between phase wires and the motor shaft. I checked this on my 85165 motor on my outboard engine EV and I see infinite resistance between phase wires to motor shaft our motor case, as I would expect.

Also, I do not think I have any leakage of electricity or water from my battery/ESC box since I do not feel any shock until the motor is powered at about half throttle. No shock when static/low throttle. I wish the battery box was the problem - would be easy to fix ![]()

Flite prop. Search forum for confirmation if you wish

![]() Anyone have a used one for sale? I expect they use a threaded motor shaft with pin, not splined shaft, correct?

Anyone have a used one for sale? I expect they use a threaded motor shaft with pin, not splined shaft, correct?

Is the safe continuous motor power 3 kw, with just maybe 10 second peaks to 6 kw? I have not felt my motor get beyond warm to touch. But I am big and heavy at 6’4” and about 230 lbs. I expect that on foil I can cruise at 3 kw but when just on a “plane” and not on foil I am cruising at 3-4 kw at 10-15 mph with the white prop. But I do not want to “fry” another motor.

Is moving the mast fully forward in the mast track the equivalent of moving my foot stance also a few inches forward when on foil? That would give me a bit more room in front of my battery box strapped to the board.

My 65161 with fliteprop and gong curve xl gets 1kw onfoil on a perfect day at 25kmh. Get the fliteprop its the best bang for your $.

Good data point - thanks! Current price for the propeller from the Flite web site is $50 + $10 shipping in US. A good price if the performance is quite a bit better than the std Flipsky white prop and it saves me from burning out a 65161 motor. And a far lower price than say Flying Rodeo from what I see here.

Can also buy from electric surf co in Austin TX Fliteboard Propeller– Electric Surf Co

Price does seem to have gone up at some point, used to be $35. Still a bargain price for a good prop. I can usually get on foil with under 3kw with a 65161 on my 1300cm2 wing (but I weigh 145lb) and then cruise around 800-1000W. Even with added weight I would imagine you should be under 2kw easily while on foil

Thanks - I have placed the order there for the Flite prop.

Note with the flite prop you will need to ream out the center. It takes an 11mm shaft and Flipsky is 12mm. Can be done with a lathe or a drill press. Can also do it by hand with this 3d printed guide (how I did it)

Thanks - I am hoping it will fit in my mini-lathe chuck. If not I will need to get the drill guide printed somewhere - ran out of space for a 3D printer.

Only a small amount of material to remove and at the time I didn’t have a drill press. I just freehanded mine with a new reamer bit and a good drill.

I do have a bench top drill press so that would be the other option though need to be careful to stay centered on the hole. Appreciate the input.

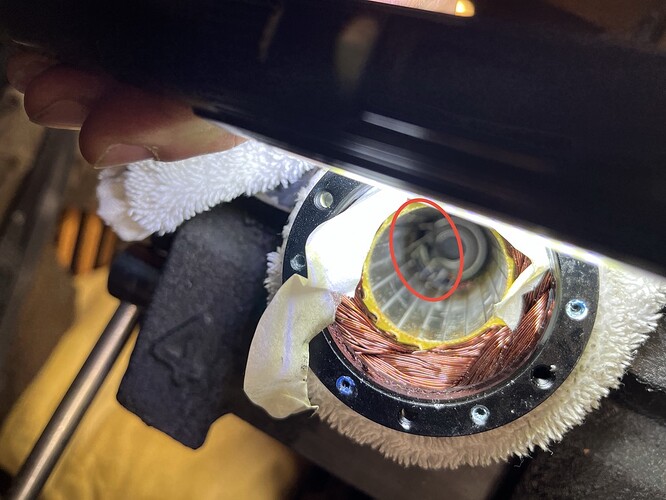

Here I believe is the culprit. Tough to see in this photo but it appears that the phase wire bundle is held in place with some “strings” and the bundle is up against the shaft at the rear of the motor. The only explanation I can think of is that either the bundle was not tied in place properly or the wires were pulled from outside and whatever strain relief is used was insufficient. I have another motor (Maytech) and white looking mostly identical, it does not show the bundle here. My guess is that the bundle rubbing against the shaft eventually wore out the insulation and caused a phase wire to contact the shaft. I have replaced the motor with a new one and no longer have the “shocking” water, nor any conductance between phase wire and shaft. I am hoping that the bad motor is fixable perhaps by removing the back plate where the wires enter and moving the bundle away from the shaft, and re-covering the worn insulation somehow.

I am a bit surprised no one else has had this problem occur and described it here.

I also bought the Flite propellor and look forward to trying it. Noted that the pitch is reversed from the white Flipsky prop. Bought a set of cheap reams including 12mm and reamed out the prop, but need to be careful to get the right depth. Centering seems to be fine.