How did you fill the motor between the magnets with epoxy without flowing away?

I used Epoxy with a lot of micro balls and spinning it every now and then slowly until it was hard enough.

Can you provide more info on why you needed disassemble your ESC? I bought a FlyColor Xcross HV160A ESC and it doesn’t work, just wondering if it has the same issue as yours.

@mekanism

I accidentally ripped off a component when I disassembled the aluminium cooling plates. I did this in order to mount it in that aluminium clamp to get cooling on both sides MOSFETs.

If you did not mechanically work on your ESC and something could have been broken off in a similar way I expect it to be a different kind of problem.

Had a great time on vacation and emptied a total of 15 full batteries. I had the Indiana kid aspect wings with me, also calle “ride”. With the 1500cm2 wing I was able to do quite some pumping and training of transitions. The smaller 950cm2 wing was getting really fast and fun, but quite hard to pump, since only mod aspect ratio.

No issues with the Bopla box. Great recommendation @hangloose

Only some small corrosion on the aluminium where it is close to the carbon board and water likes to stay in between.

Have a look on IG

Now working on some further ideas - smaller/ lighter battery and waist mount.

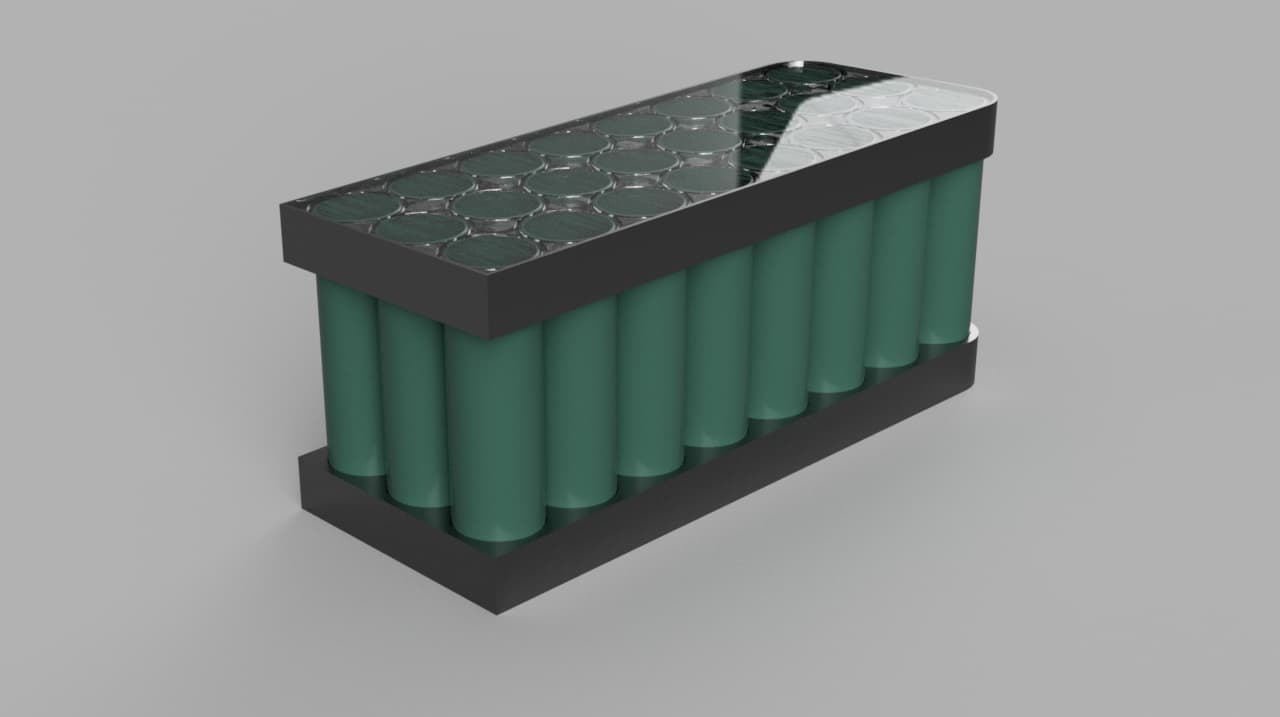

I sketched up this design quickly. The idea is to pott only the cell terminals, strips and wires. Benefits could be better cooling of the cells an lower weight since less potting material.

What do you think about it?

@Bzhwindtalker you have a lot of experience with potting batteries - any issues with gases from the cells?

Well I mostly potted some old batteries, and had some self discharge issue, I can not tell if from potting or just the cells.

If you have no need for structural holding, maybe some kind of foam or silicon would be more suited.

Here is the kind of stuff used by tesla in their packs :

Seems like you had a great time ![]()

@heiguga @S_Roger

Sorry for not replying.

I was and still am busy with a new propeller driven assist design. I’m trying my best to get it finished for vacation next week.

The Jet drive is giving me a hard time. So I started with quite a lot of pitch. It turned out that the motor was not producing enough thrust and current limit kickin in already way below 30% duty cycle on the motor bridge. With a high speed low torque motor that means making only little power. I had this configuration once in the lake and I could only taxi around slowly before the motor cut off.

So I lowered the pitch resulting in broken rotors - as you might remember they where Nylon SLS printed.

Latest addition is a metal rotor I just received this week. It should neither flex nor break and this will be the last chance for this motor/ jet combo from my side. If it won’t work I’d rather switch to an outrunner configuration with jet. Main reason being better weight to power ratio.

Another update on my before mentioned v2 foil assist.

I gave the body mounted approach a go.

The base of my hip bag is made from neoprene with a PE sheet as stiffener inside. I’m quite happy with the functionality but next time I would go with a kite or wing harness instead of sewing it myself.

The waterproof bag I welded from TPU coated nylon. It closes by wrapping which worked really well. Not a single drop of water inside after 3 extensive swimming/ foiling sessions.

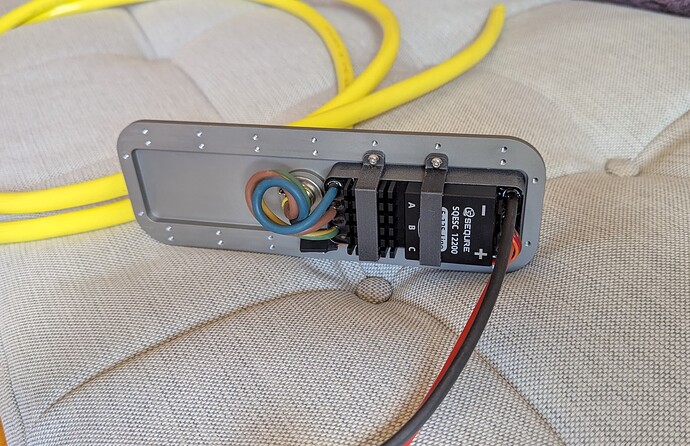

The core of the bag is the CNC miller heatsink which doubles as a rigid base for the cable gland.

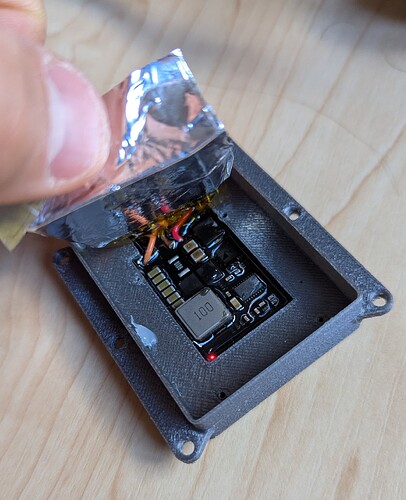

For the receiver and BEC I printed this enclosure. After assembly I noticed the remote would not bind. After some tinkering I noticed it must have had to do with the ferrite shielded inductance. Some aluminium foil under the receiver (of course isolated with capton tape) solved the problem. No heating and no more range issues.

The battery is potted only around the poles. A basic guard ensures mechanical protection for the cells.

The mast base is custom milled to fit Indiana aluminium masts. It incorporates some space for a connection of the motor phases which is potted for waterproofing.

For extra safety I added a dyneema leash as second layer of safety. The cable has a neoprene sleeve to make it floating.

Sadly after a lot of work before my vacation the assist did not work as hoped. By now I narrowed the issue down to the motor which was initially a Flipsky 6374. It simply had not enough torque and stalled at 30-40 % throttle. No improvement by changing props, using bigger front wings etc. Therefore I switched back to my old BDUAV 6384. Though I can’t really test here at home.

Jet drive is still not tested in its latest configuration.

Clean work!

How did it go on holidays riding?

Would you have the 3D file for the ESC by chance?

Can explain and share stl file for potting battery?

I want to do same work on mine and thinking how to solve the problem of waterproofing well both the balance plug and the power plug

@Bzhwindtalker

Sadly no foiling at all since the weak motor. I replaced it with the BDUAV just after my vacation and had no more chance to try. At home sadly it’s complicated to do testing in a legal way ![]()

I did not sketch the controller sorry, just som basic mounts and a frame for potting. It is also filled with epoxy ![]()

@Allix

There is not much to it. Just a cel spacer similar to the ones you can buy with the addition of a box shape on the welding side. After installing the cells in the spacers I glued each one with a few drops of epoxy in order to seal them for potting. Then after spot-welding, soldering cables and checking functionality I potted both sides one after the other. The plugs are not sealed. Just a regular XT90S and SubD 15 pin for temperature and balancing. Some battery grease to protect from corrosion. The idea is not a entirely waterproof battery but having a second layer of safety in case the bag collects a few drops of water.

Are you doing the CNC work or are you getting it commercially done?

CNC parts where done by JLC, it is not cheap but reasonable and always including anodising.

For the mast base I paid something around 150€. I expect it to be way more expensive doing it myself or by a friend.

Were you able to get the 6374 working with the Sequre ? I have the same problem

No its simple to short of a motor, to little kt value and not enough torque even with maximum current. Therfore I switched back to the good old BDUAV 6384

and by limiting the battery current on the Sequre ?

Am I missing something? Why should a reduced battery current help with low torque/ stall issues? Basically the torque is proportional to the current. The only other reason I see is if the esc would loose positioning. But usually this should not happen somewhere around 30% speed.

It was a simple beginner’s question; I don’t know much about it. ![]()