Maybe the reason is the ASA. I use formfutura apolloX, it does not warp a lot. Build plate 90 degrees on an enclosed printer.

Feels like a temp calibre issue as we had to swap nozzles recently.

The asa blades where very nice printed without any support but since that Many issues.

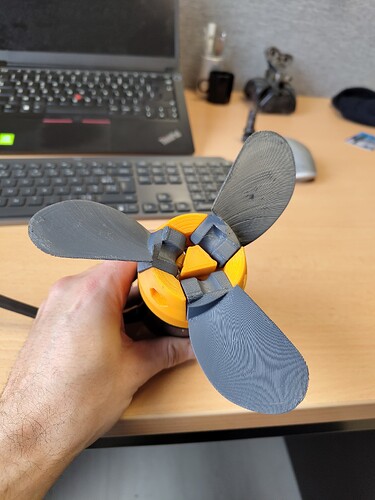

Here is the 3 balade hub installed. Folds very small

What about using petg for the pod?

Still 6384 Saite. Cheers

First print was a complete failure, second print in appolo x also had issues with layer adhesion, maybe salvagable with epoxy casting.

Based on the amount of warping of asa, I will probably stick to ABS in the future. Love/hate relationship with 3d printing!

Had tevo black widow, and now those two flashforge A4

Went with glass fiber warping of the asa print.

Mega messy but should be super strong now.

I have to reprint the blades hub, it broke during assembly, the orange PLA is really bad.

Just missing the top scratch ribbon.

Now printing two New hubs with looser tolerances, in petg and asa appolo x.

Does strap variants unlock less drag or is it just for quick assembly?

I feel like drag will be comparable, maybe a bit higher, but assembly Time is 1/4th of the other slid on mount.

Hopefully one of those will work!

Asa and petg

Appolox and hdglass from formfutura.

Really disapointed by the pla I got from grossiste3d in a 3kg Roll !

Next i’m trying kevlar ASA.

Hub looks great… better than the FD 3 blade i bought whick looks like they had an off day at the factory !

Still have some issues with the layer adhesion in ASA.

It’s solid, but when the blades bolts are tightened I got a crack.

Do you have pictured of your FD hub? It’s sintered powder?

I print with the cheapest ASA filament from Eryone and have no problems. Maybe it’s all about the print settings?

My blades also printed fine, but after a while they show splitting around the hole on the back. On my current 2 blade that works, I have fiberglassed the back of the blade to prevent splitting.

Did you go in the water with those blades yet?

Hopefully I’ll be able to try it in a week

Sold my slingshot quantum 100, as it is quite restrictive for pumping and too slow for sur foil.

Waiting for my takoon X glide V2 1950 and takoon slate V2 25lt.

Already ordered a smaller stab, and looking for a 1450 or 1250 front wing for surf foil.

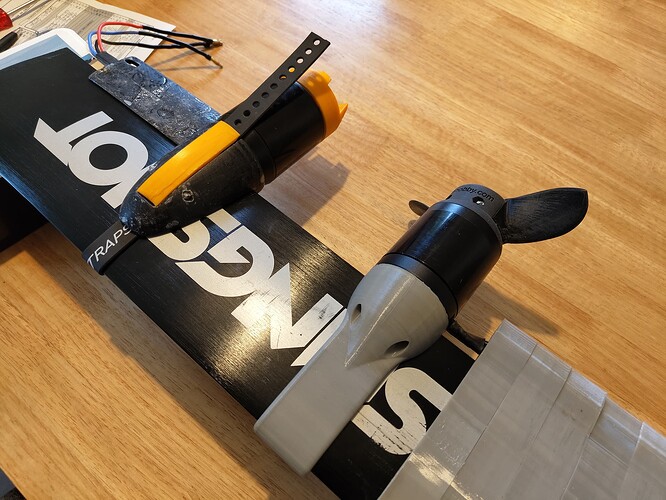

The board has strap inserts, I will make an adapter plate to locate the battery box on the front/side.

1950 is for low power efoil, and pump foil. Flat water starts on the 25lt will bring some new challenges.

Should be interesting

New setup being worked on, Would be on the water already if my new foil was not stuck in transit due to Yémen pirates (info from takoon)

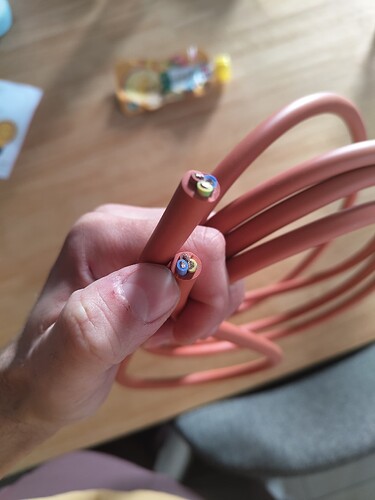

The silicone wire I got from amazon, if is quite flexible and high quality.

The blades in asa, I tried to anneal them in the oven, they deformed heavily, I have to print new ones.

Cable held by HD adhesive velcro.

To avoid box issues like previousely, it is both held and secured by voile straps.

Are you still using 12AWG cables ?