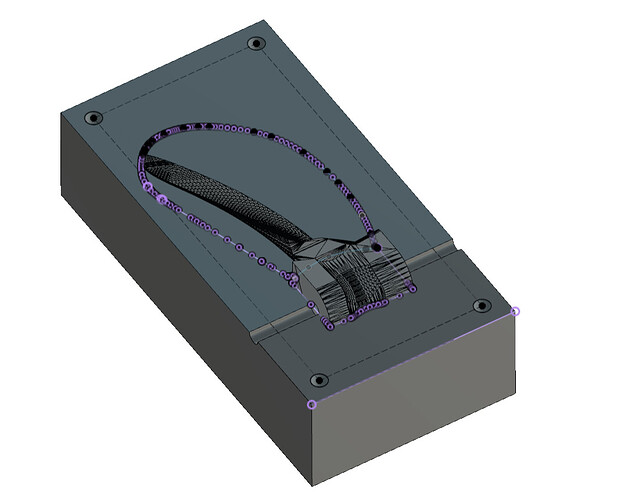

anybody did a mold for forged carbon/glass blades? having some trouble to draw something from the STL files.

No, is the problem the stl file mainly? I convert to step and use that, sometimes some parts need to be redesigned based on the stl but for a mold it should work without?

already converted to STL, and reduced the polygon count, but edges and faces makes it hard to process in projections and extrude to operations. I’m also on a 10 year old surface 3 at home, not helping my case.

Agreed, converted stl is shit to work with. Maybe you can get a fusion file or original step file?

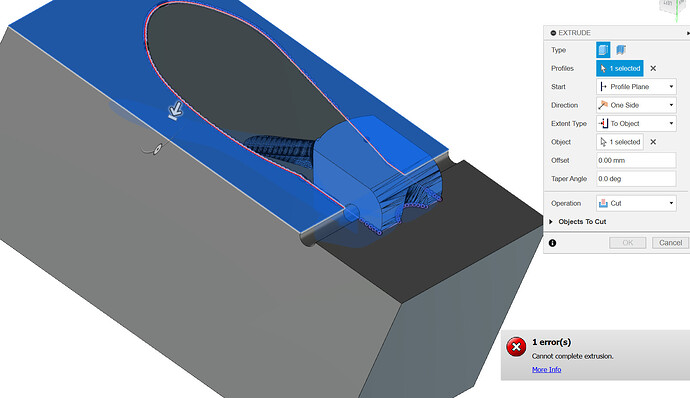

How about just a boolean cut on a block with the STL blade?

Then split the blick in two after adding a resin escape channel.

The blade needs to be a pressure mould if you are using forged carbon epoxy, no?

Grease, Fill, clamp, done ![]() (joke)

(joke)

If the polygons create uneven surface maybe a gelcoat prep can correct that?

Issue is with the blade twist, and parting line.

If you just do boolean and parting line, you have overhangs and spots that can not be released from the mold. When projecting the blade body as a reference to do the parting and “compression” shape, the STL artefacts fause a lot of issues and errors.

This most interesting topic should be the subject of a separate thread…

Virus has videos of how to create molds for props. It’s actually really easy.

Yes, but the problem is the stl artefacts causing poor 3d data. Sometimes you just got to bite the bullet and redesign the stl to get good curves and surfaces.

Another option if the main objective is durability i’d go for a thin vacuumed glass or carbon twill on a PC 3d print prop (imo pc with 10 walls is enough wo laminating). Use 3m 90 spray glue to fix the cloth perfect then apply resin with brush and vacuum it. Can do a batch of 3 props at the time in one bag. Finish off with dremel tool. 1 hour of work per prop once printed. Have you tried putting dots of silicone on the folding prop base to dampen, works wonders for me.

I’ve done a few propellers like that but they have been fragile, one minor bump and the fibre starts gradually delaminating.

I think the pressured mold gets you better overall results, and not really a lot more work once the mold is made.

Sucess today with 3 blade prop, Quick release mount, 25ly board !

Very happy about that, new possibilities open!

Was with a think mast and 2000cm2 foil.

Should be no problem on m’y pumping foil. For the 1450, I am not sure, but should be doable with full battery.

Looking forward to test all this in choppy water to see if it is still possible to do.

the motor pod was lower than the position it was designed for, I think most of the water spray comes from the exposed cable above the strap on support.

Also tested a 4" gong cube board with similar motor setup, it was very fun with such a short and high volume board.

The 3 blade is super silent. Had some issues as the blades were stuck closed when off throttle. Maybe my hub allows too much angle, and the blades go beyond the angle where they can open by them self. They also need some sanding to help smooth opening.

Better support for the box, I have to figure how to make it very rigid on the board down movement for pumping, as the box ineria made it jump a bit with the previous improvised alu mount.

Now the box Can not move side/side and front/back, but UP/down IS still a possible issue.

Try some silcone along the outer edge, between board and plate. Sticks surprisingly well. Multibond type glue does not, i lost a plate with that.

Reprinted in ABS with 5mm walls, now it is very rigid and strong. All in all, I had 5 prints of this same part on 3 different printers ![]()

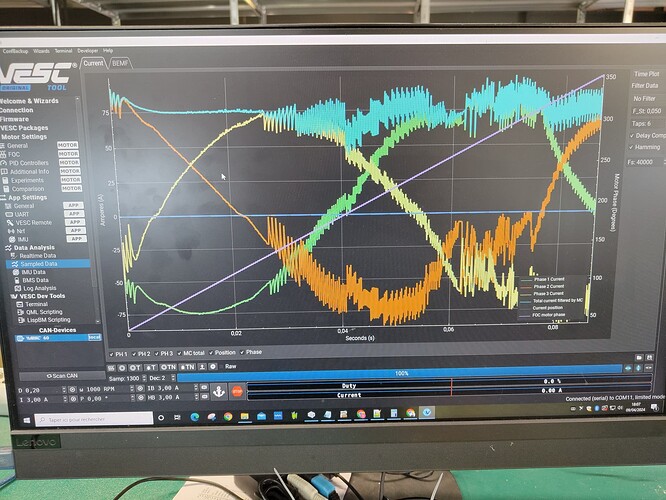

Received a “free” replacement 60100hp, it has the exact same issue as the first one. 50A phase was fine, but 75a gave this!

On the foil, with the tree blade and 120kv 6384, the issue is almost not perceptible, but I would use the 84100hp any day over the 60100hp.

you mean it’s not noticeable on the water with the 60100hp ? The curves look really bad though - i bet there’s a difference in the sound?

I’m planning to do it

looking forward to the result!

On the ouest coast for a few days ! Have 1450 and 1050 front wings to try. 1m swell with offshore light wind for 4 days🙏