I tried freeze spray but didn’t work, the aluminum thermal mass wicks away any temperature difference in an instant.

Shell is curing in vacuum now. Peel ply first since i’ll cover it with some added layers later, then three layers of 200g/m2 carbon/kevlar cloth and some UD strips:

It’s always a nice feeling to close the bag and anticipate the result. ![]()

I want carbon cloth all the way into the corners, if i’d done a 3mm fillet like normally the foot would’ve been mostly without fabric so i skipped it, therefore it might have some bridging gaps.

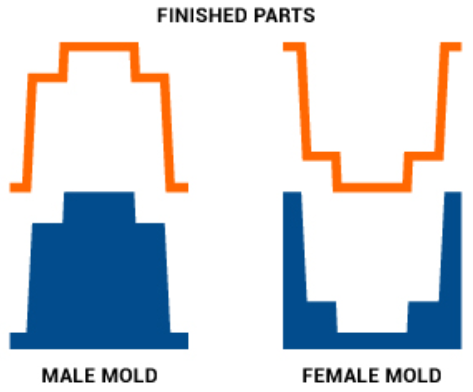

One to two degrees of draft angle is what they use to mold carbon parts or tubes… 'Composite Mold Construction Guide | Fibre Glast so that friction doesn’t cumulate during the part release operation.

In all friendliness, sometimes you should refrain from posting @SoEFoil ![]()

Of course a draft will help but it’s not appropriate here since it would introduce play in the connection. Tubes are also mostly straight walled.

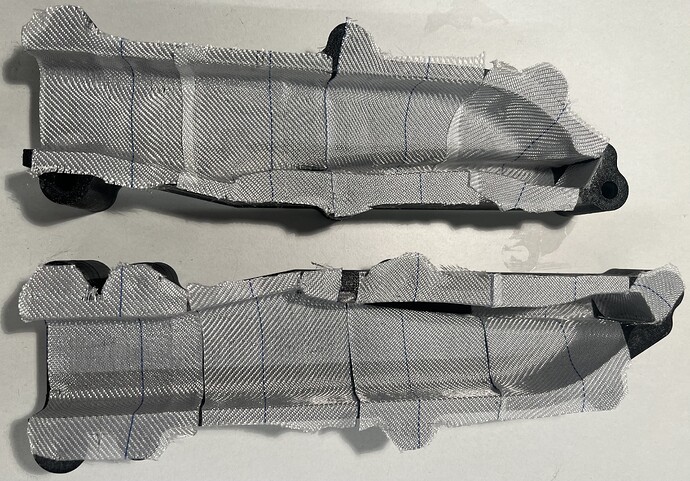

Demoulded, everything looks good so far. Some small bridge gaps (as expected) but nothing too bad, i’ll call it a success😄

Peel ply is still on in pic, this is why it looks so rough.

You seemed so desperate that I had to try something ![]() The last mainstream composite channel I watched applies 8 layers of release agent + IPA on an aluminium tube used to mold carbon tubes.

The last mainstream composite channel I watched applies 8 layers of release agent + IPA on an aluminium tube used to mold carbon tubes.

I think it’s the temperature that does it, i cured at 60-70 deg C, at 110 it would’ve been more thermal expansion. The release wouldn’t have been better with more coats as the part was not sticking at all when the pressure was gone.

Getting there😄

Adapter halves are assembled and curing, i’m so happy that the inserts didn’t get filled with epoxy!

Let’s hope it releases more easily from the fuse this time. After that it’s just some outer layers, sanding, 2k clear coat and then it’s off to the water!

Well, getting the fuse released wasn’t exactly a lot better this time, i had to pull it off with a chain hoist. I knew it might be tough since i packed a lot of carbon into the mold before closing it, again creating pressure on the fuse during curing.

On the positive side, the adapter is proven to have a tight interface which can take some 100 kilos of pull force

Hope this is the final layering so i can ride it soon😄

I used the recess in the wing as a mold and coated it with a talcum+epoxy slurry to build a filling layer, then pressed down the adapter and added fabrics.

Bottom reinforcement is 6 x100g/m2 UD

Top is 2x200 g/m2 carbon/kevlar + 2xUD carbon

I forgot the peel ply - but what the heck, it’ll be great anyway, just more finishing ![]()

I tested the wing and adapter today, might upload a video later🤙

Riding it the first time was a bit like Bambi on ice since it rides so differently compared to what i’m used to and conditions were a bit harsh - but i’m really happy with the ART999 wing! Lively, carving, easy lift, efficient - it seems to have it all!

Here goes, just a short ride video. Foggy, and what the christmas movie industry would call a blizzard, but really is light sleet😀

It was frickin cold anyway and careful riding, i didn’t want to crash.

Once you leave gong, you realise what was wrong ![]()

what a nonsens. To be able to give such a dumb statement, you need to have used EVERY gong foil availible

Nice helmet! 20 chr…

I’m sorry you lost your sense of humour somewhere…

Yeah, some uninspired views but i hate using a selfie stick, not worth sacrificing a nice ride to get a video😃

I think it is more likely that you lost something