With the focus on Waydoo there is a lot of knowledge being exposed in this group.

I thought it was time to share how we build our DYI batteries and trying to share good ideas on how we can increase safety. Also honestly I do not believe that I build better batteries than Waydoo and I would like to keep my house.

So, I come from mechanical background and try to always apply the KISS principle on projects, sofar I have made 3 battery packs >1,5kwh for efoil and managed to short single cells once or twice in the making, which means bringing out the fire extinguisher.

The Battery

Like @kotnascher and other I use the 15€ Max004 enclosure. It fits my board, is watertight and has carrying handle.

I 3D print connection-blocks for the shortside that contain female 8mm bullets and a male DB9 connector for balancing. I have not used internal fuses on either power or balancing connectors.

To my excuse the balancing cables are extremely thin signal cables that can not carry >10A.

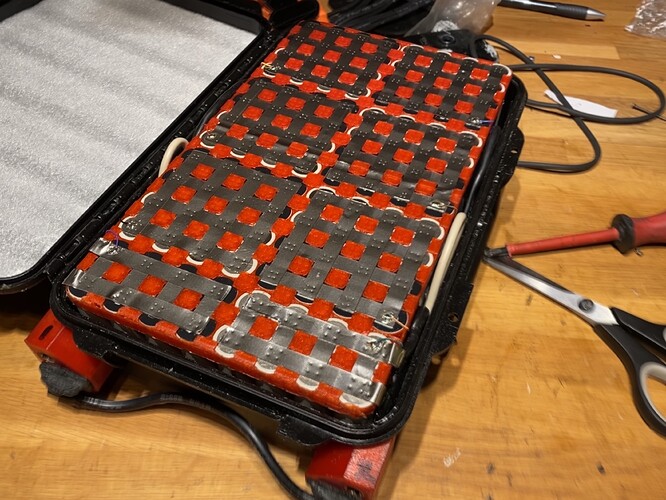

I use 21700 cells and either do 2mm cell spacing when doing 14S8P packs or only 0,5mm spacing when doing 16s8p packs. I weld using single 10x0,3 strips and a setting of about 80J for welds. I am not sing any busbars.

When tested I wrap the package in a couple of layer of heat proof Kapton tape. and use thin 2mm shock absorbent layer top and bottom to have the cells completely fixed.

On the Max004 I remove the rubber seal and apply ample amount of Sika 291 marine sealant, and keep battery under pressure during the night while seal is curing. Then put 2 M4 screws through the lid to secure it.

The charging

Like many of you I want the battery packs to be cheap and contain minimum amount of components so I do external balancing. The setup includes a 24v 50A power supply and 2 ISDT T8 balance chargers, that I always have on max 1,2kw limit, meaning 2,5A per cell.

Many cables to connect for every charge, but it has worked flawlessly for at least 100 cycles so far.

I have no secure charging/storage for my packs yet. Thinking of getting a alu box with 1,5mm thickness to fill with some sand. Anyone with real experience of fire in similar one?

The board

For me the focus has been on building the best simple waterproofing, thinking a dry battery is a safe battery.

The lid & box design in 3mm alu is a bit “steampunk” but it means that I can use a very simple 5€ car-door seal and use the rim of the lid to keep the compression constant. The lid is locked only outside the seal by using horizonal pin into the rim (like a normal door lock). I have not seen this very simple design here before. It has worked well solar, but I mostly ride 190L or 140L inflatable round the box, so it is very seldom fully immersed in water.

The ESC box is same design as @pacificmeister has documented here, for what it’s worth I had not seen his design when I made mine.

Due to the KISS principle I do not have any external fuse either or any cheap FET-antispark switch.

I use a normal 200A boat switch 15€where you can switch between to 2 batteries separately.

I connect a 50Ohm resistor between 1 and 2 selector. When I power on I go first one 1s to 1 position and later put on 2 that has direct connection to battery. I have not seen anyone do this, but it has been flawless and I can recommend.

I would value any input on how I could improve the setup especially regarding safety and also hope others are willing to share here or link to earlier posts on these subjects.

-7*C outside now in Sweden and no ride for almost a week, finally some time for reflection and improvements for the 2021 project.

Cheers, Mattias