Very clean job! I dig that hatch, where did you get it? Do you plan to glass the internal of the box or flush in a wood or plastic box? I’m asking because I’m at the same stage, already prepared the recess on the board, like you, an Okumè plywood (6mm thick) box with cover, which I might just use as “mold” to do the box glassing the cavity in the board…

Being mine an old kite-race carbon board, I cut the deck and pull it off, so i could reutilize the carbon panel as top of the box (reinforced obviously)… but then, how did I get to seal the battery cables leving that box direct to the ESC box in the rear of the board? I mean, where do i fix the PG9 cable glands, if I don’t have a rigid wall, like a plastic or wood box? My plan was to separate and insulate battery and switch from ESC, receiver and water pump…

The more I see all your progress and photos, the more doubt and re-thinking I have!!

I glassed over my box. Even though I place a waterproof camera case inside the box. Glassing the corners of the box was a bit tricky. I would recommend glassing the box separately with a vacuum bag. Vacuum cleaner pressure is enough. You can also insert a trash bag filled with water that presses the wet glasfibres against the walls and corner. I had small areas where the glassfibre did not contact the foam. These areas become holes in the sanding process that need to be filled. You can laminate multiple layers at once.

thank you @MaB . im also going to glass the box with the vacuum technique. i will also seperate the the esc and the waterpump in a seperate box but i’ve not the final decision about it. next week, i’ll get my waterpump and then i’m going to know how much space i need. the hatch is from a marine store.

It seems like there are cheap complete boxes available:

We only need to find a flat version.

yes, but like you say, we need a flat one and i’ve not found one yet.

Die Mobiliar? Are you based in Switzerland? Where?

Nice job and progress!

Had the same thought when I saw the pictures–nice build by the way.

I’m from CH as well.

Very clean build! Looking forward to the next update.

I thought the same, I am close to Lausanne!

Very clean build!

He didn’t mix any epoxy yet : )

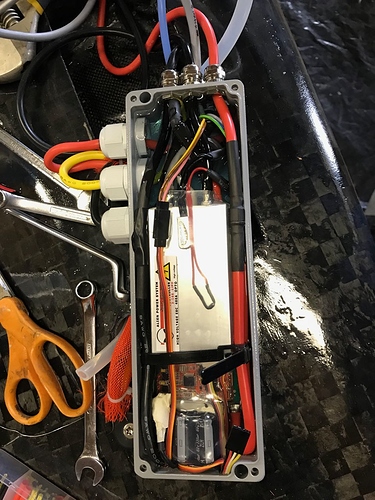

I finally re-finished my board, added compartments for esc and batteries plus carbon finish. But, once ready in the water, the motor would pulse at very low power (between 5 and 20% every 2 seconds)

Not sure what is happening? Maybe, some water is getting to the cables (I run in freshwater)

What is the device at the front?

It’s a sailing GPS

I am scarred that my Pulsating motor might come from the electrical sealing gel that I poured in my ESC box?

www.cef.co.uk/catalogue/categories/sealants-magic-gel-sealant

Nice progress @Clarin! Bummer with that pulsing. I have had that too and and have still not fully resolved it. Does it only happen under load? Could be noise from the esc at higher loads affecting the PWM signal to the ESC. Twisted signal/ground wires help, also some esc makers add a ferrite bead. There is also discussion about ground loops on the RC forums.

Add capacitors close to esc inputs? Keep all wires close to decrease inductance? Decrease wire length from batteries to esc?

@pacificmeister Your are the best! it was some kind of interference.

I had to put a ferrite plus move the Fail safe closer to the ESC. Apparently carbon fibre is not helping.

Now, it’s back in the water for some test, sadly only in a few days

Video of some the interferences: https://youtu.be/qJbJeasN7N8

the last cut is done, i‘m ready for glassing. a seperate box for the watercoolingsystem and the esc, behind the batteriebox and remote box.

Looks great, congrats on the progress.

Are you planning on water cooling, or are you using passive cooling with the aluminium box? Are you putting anything over it to protect your feet?

thanks. i would like to go for a watercoolingsystem. what are you meaning about protect?