Hello Everyone! I have reviewed my blank from Greenlight Surf. This will be my first time ever shaping a board but I have previously worked with fiberglass. Does anyone have a template I can print for the shape of the board or somewhere I can download one. I was aiming for about 5’2” x 25” x 5 1/2”. Any recommendations on board size is greatly appreciated!

Dimensions are good in my opinion, not a pig and not too complicated to learn on. I’d rather make it slightly narrower at 23-24”

What’s the shape of the blank?

I’d recommend to just sketch a design yourself and upload here to get feedback. it really isn’t very critical how it looks as long as the basic dimensions are good and you’ll be more proud of the result.

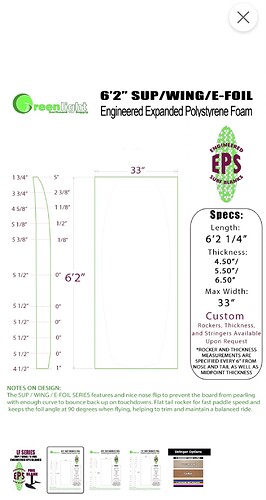

Here are the dimensions of my blank. Slightly narrower sounds like a good idea as I won’t have to order wider glass. I see a lot of guys use carbon but I have a good amount of 6oz E glass I plan to use. Will that be strong enough? The foam is 1.5lb/ft3, do you have any advice on a glassing schedule? I don’t have the equipment to vacuum bag so I will have to hand lay it.

You could try with these wingfoil style boards and reduce to your liking:

Tough question… i’m guessing a bit here but I think 1x6oz might be a bit too thin, you can do a test on a piece of the foam to see how it behaves under load

I think it will be plenty strong with a 2x 4oz layup but depends a lot on compartment and foil box design and reinforcements. Denting from the rear foot won’t happen as you’ll be standing on the hatch which cannot be allowed to flex too much to keep the sealing.

Do you think 2x6oz layers would be too heavy? Also I was planning on using a foil track box cassette from Fiberglass Supply and had ordered one but I am seeing a lot of people have the compartment extended all the way until over the mast. I assume this would make it easier to route wires but is there any other benefit?

In the total weight, no it doesn’t add much, if that’s the cloth you’ve got.

You can always do one layer, check it and add wherever seems necessary. I never tried that low density foam so you might need more than i think to spread the load.

The box is at the mast mainly for weight distribution. The battery adds a lot of swing weight

Will having my battery in front of the track box cassette effect riding very much? I planned to use conduit tubing to pass the wires through the box and and down into the cassette like some other builds on here. I assume this would only push the battery toward a few inches but I could be wrong. I am in the process of building the 14s8p molicel 21700 for the board.

It’ll work, you can put it where you find best as long as it’s in the rear of the board.

Is vacuum bagging necessary? I see most people are vacuum bagging their boards. I had planned to hand lay it but I think it’ll be hard to get the box for the electronics without it. Do you have any tips for glassing the box?

When I was making my firts windsurfing board I did not use vaccum bag, but i regret it a lot. I was happily laminating and everything was awsome, until I can to see results the other day, and there was a huge ballon on the center of the board. That is why we use vaccum bags, so they prevent this from happening.

It’s a steep learning curve with vacuum bagging, it’s hard to get right the first time. You don’t really need it, but it helps the fabric to follow tight corners.

One good tip is to use 3m super 77 spray adhesive to drape and fix all fabric before applying the epoxy.

Beware that it can dissolve the EPS core on the surface if you apply it too heavily, do it with a light coat on the EPS from a distance and apply a light coat to the fabric also.

This allows the cloth to be placed, draped and trimmed, even repositioned if you need it (only a little, quickly and carefully!)

This way it’s easier to get the lamination good.

Build up the laminate in one layer at a time, it’s tempting to try to finish all layers in the laminate in one session but this is much harder to do without errors.

After curing wash away amine blush with warm water and a sponge, then a sanding with 80-120 grit between each layer (or use peel ply, it improves the surface quality) - all for an easier setup and less risk for imperfections.

You can apply some pressure on the fabric in the box cavity with a large waterproof bag filled with water. The bag won’t get stuck to the epoxy as long as it’s plastic.

I used 2x extra large vacuum bags used for clothes storage and taped them together, you can use a standard household vacuum to suck the air out.

I also recommend using peel ply and breather, as mentioned above use a water bag in the compartment.

All edges and joins in the fabric came out super flat.

I really like this idea I think I will give it a try. Was it hard to get done? Do you recommend laminating the electronics box first using plastic and filling it with water before putting it in the vacuum bag? I also thought about making my own bag with vacuum bagging material, I saw other board builders doing it this. I think getting an entire vacuum bag setup is a little much so I think I will just try this

I will definitely use the Super 77 spray to stick the glass down first. Could I also maybe use sand for less mess? I think it would work similar and have less risk of disaster.

I don’t understand, please clarify.

I was referring to how you recommended to use plastic to cover the electronics box when laminating and fill it with water to apply pressure to the fabric. I was thinking sand may be less risk instead of water.

Measure the volume of your compartment then put that volume of water in something like a bin bag and tie a knot in the end to seal it. Once you’ve done the laminating add peel ply and plonk the water bag in. You could always double bag for extra protection

Did you laminate the electronics box first and let it cure before vacuum bagging? I also am almost done shaping the blank and noticed a pressure dent where I accidentally leaned on the board. It’s not very noticeable at all but I would like to fix it if I can. I think I will try to fill it and sand it when I seal the board as the board is EPS ,and not PU so I can’t use heat to remove the dings…

Yes, I laminated the electronics box first and let it cure.

I had a few imperfections on my EPS so I used a light weight household filler to smooth them over.