Lake Bled, lake Zbilje…

Lake Bled is possible? I thought it is forbidden.?

No, Its legal to ride there! This is recored on lake Bled https://www.youtube.com/watch?v=PuwxyeeNFoI&ab_channel=MaticVrecko

Found this VESC on Aliexpress → link

Looks pretty much the same as Flipsky, at least mosfets are of the same brand…

Anyone used it?

No, but some more information here:

Some progres on my end ![]()

Started shaping the board. My first intention was to make a 3d model and use one of local CNC companies to mill it for me. But in the end I decided to shape it by myself using hot wire and “muscle strength” ![]() .

.

XPS foam, roughly sanded:

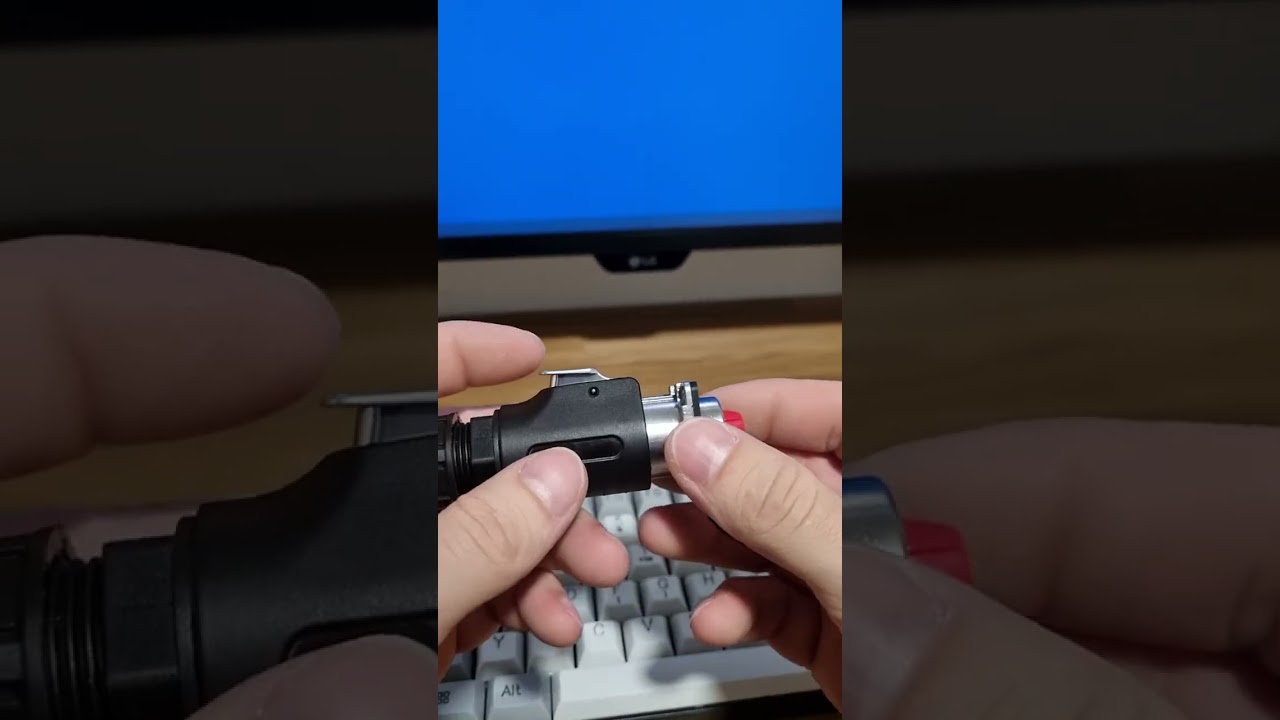

Also created a waterproof AS150 connector by joining a cheap waterproof connector [link] with AS150 connector. Some 3d printed parts needed to make it work. If interested I can share files.

As150 is good but I suggest you test the connector for water ingress. IP65 is not really waterproof and I couldn‘t see a seal ring on the pictures of the connector. If water gets into the connector you will get corrosion of the copper and the solder joint. At high currents it will heat up and melt the case of the connector. Happened to me (in freshwater use).

These work with as150 but you can‘t directly mount one side to a surface:

US $2.94 39% Off | 2Pcs Outdoor IP68 Waterproof Junction Box Cable Connector 3 Pin Electrical Wire Connector Terminal Block Sealed Retardant Plug

https://a.aliexpress.com/_mr190UM

You need to drill out the center piece.

There’s a seal inside that should take care of waterproofness. Will upload pic later.

But it probably wouldn’t be a bad idea to do some additional tests  .

.

I created these because of simplicity: snap on VS screw on.

And being AS150 these are also anti-spark.

ip68 waterproof 100A, isn’t it better to use this? There are electric hydrofoil factories that have been producing 45A for two years without any problems

There are few differences that matter → at least to me

- Simplicity of connecting:

Weipu connector looks to be screw on

Mine is a snap on - Anti-spark

Judging by picture, Weipu connector is not anti-spark.

There’s a AS150 connector inside mine so it should provide anti-spark. - Exchanging terminals

Possibility to exchange only terminal part of AS150 connector. But I guess if something goes wrong with terminal then whole connector will be faulty…

Here’s picture of disassembled connector with visible seal:

I think these are great! Snap in is far better than the screw on.

Hello.

Im from croatia.

I and my two friends are mainly foil on small lake near zagreb.

If you are interested we could do some group foiling.

We could come to bled or you could visit zagreb.

Hello,

great to hear that we are neighbours  and I think thats a great idea. There are few people from Slovenia like @flytomaz tomaz building too, so could set up a little meeting… but first I have to finish my build (may take a month or two)

and I think thats a great idea. There are few people from Slovenia like @flytomaz tomaz building too, so could set up a little meeting… but first I have to finish my build (may take a month or two)

BR

Glad to hear thare is so many of you.

Yes that would be great.

Balkan efoil meeting😆.

I also neeer visited bled so that would be nice to.

Ok, we have whole summer, can you finish it unthill the end of it?

Yea of course, plan is to finish it till the end of june. I have all the componencts and all the electronisc, so I just need to find time for lamination of the board and battery case from mould.

Br

Ohh great.

I remember doing my own.

Laminating board is not problem.

It is done quick, but after laminating, al that sanding and filling little bubbles and sanding agin, that is big job.

Will you do vacume bagging or?

Yes, plan is to use most carbon fibre 200g twill on board and on the parts like hatch top will be used fiberglass for signal penetration. I plan on using vacume bag, than sanding and using kit to fill holes. The issue that takes most of my time is cad modelling all the inserts in the right place as well as for foil mount and for latches and holders…

Hmm, mine is oposite i used fiberglass on board and carbon for hatch.

I dont have problems with signal penetration eaven with whole board submerged few cm under water.

Best would be to put external antena in nose of the board if you can.

If you think cad modeling is issue wait unthill you get to sanding and filling😆.

But i hope you will not have to sand so much as you will use vacume bagging.

What signal do you use for remote? I use 2.4 inside my Flipsky VX3.

Br

Yes it is also 2.4Ghz wifi.