tell about this battery.

Hi,

10S10P

https://eu.nkon.nl/rechargeable/li-ion/21700-20700-size/lg-m50lt.html

The idea is to be able to charge it on the spot from a solar panel around 450W

VMpp =41-42V ; V open 48-50V I =5-10 A.

You video is private…

The first tests done by my friend VALENTIN MARINOV:

-MOTOR 65121 Flipsky Inrunner Brushless DC 65121 Motor 130KV 3700W for Surfing Boat – FLIPSKY

- propeller FLIPSKI 5" cut to 160mm.

Could you share details how you build your wings? They looks like fast and easy to build, willing to copy

Hello ,

The large wings are made of aluminum with a thickness of 16mm. They have a large aspect ratio (8.8), a large camber and a small thickness to be light.

The smaller ones are 12mm and 10mm thick, the smaller camber and the larger thickness to keep them strong.

Everything is made on CNC milling machines.

The stabilizer is made of aluminum 7075 with a thickness of 6 mm and can be tilted 3-4 degrees.

Wow, so you just take some profile with 16mm+ and made on cnc to 10mm and 12mm thick?

As understand you have some research about aluminum alloy, in our region more widespread 2024 alloy.

Google says that 7075 have some issues with corrosion. How you will defend it, with some varnish or paint?

Hello,

From a plate with a thickness of 16 mm, I make a wing, which in the middle is the thickest 16 mm.

From a plate with a thickness of 12 mm, I make a wing that is 12 mm thick in the middle.

On the wings, I make colorless anodizing with a thickness of . 20 micrometers.

Group 2 aluminum alloys (Al2017 T4; Al2024 T4) corrode most easily because they contain copper. For wings I use Al 6082 T6.

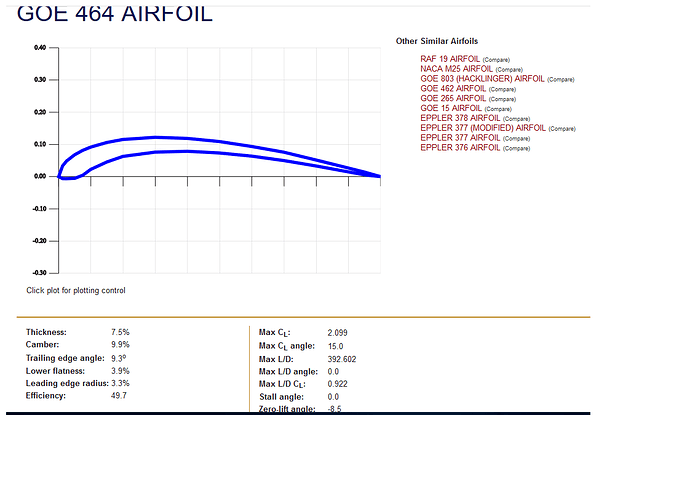

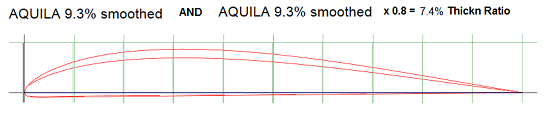

GOE464 is way too cambered. Flat on the bottom (intrados) I would say : Clark Y, Aquila,

Fwing and stab footprint ?

Front wing #1 - 1100 square centimeters

Front wing #2 - 1180 square centimeters AR 8.8,

Machine time 6h

What is the wing span ? Is it easy to turn with ?

What is the CNC you’re using ? For aluminium, a long X home-made CNC could do the job though.

If they tolerate breaching during turns, this could be a cheap way to get aluminium wings with ultra high aspect ration (AR)

Hello ,

Yes, it is very cambered, so it has a very high lifting force and becomes very light.

Nice build, love the machining!

I saw you used the apd esc, thinking about trying it also so i’d like to hear if it’s so far a success?

Did it work with the remote without issues (which remote?)

Can this esc be run with a wired throttle without a servo tester or some workaround?