I don’t quite understand the meaning of this idea. Pumping is a direct transfer of energy to the foil. Why waste your energy on elastic deformation of plastic?

It’s a challenge, does not mean it should compete with a cfk board, but get as close as possible to a usable board, with a physical challenge also for me to beat 1 minutes pump foiling it.

Latest score on this board was 50 seconds, getting there.

I made drain holes in the board, it is filling up during swim back to the dock but getting empty quick.

Core for layup version is not going how I like, lots of wasted filament. I would like to know if it is the formfutura appolox making the difference, or my home printer…

1/8 done,

because it could lead to some breakthrough - literally and scientifically…and its a great trainer for Bzhwindtalker’s mad pumping skillz. ![]()

Made some progress. Still some warping but nothing that would prevent me from doing the layup.

Fresh Roll of asa, 100w heater bulb and enclosure fan.

550g for half the board with dowels.

Waiting for the Peel ply.

3D printing has its place. I sometimes do the rails with a 3D printer as then they are pre-shaped and just bonded to the XPS making life super easy.

The usbox were printed out of cf-pla After a few failed atempt in ASA.

It folded due to delamination on first test. Afer repairs and reinforcements it lasted two sessions so far. Should have installed one or two wood stringers…

It was a relentless effort, though, really impressive that you attempted it and got as far as you did.

Weird, shouldn’t be too hard to get it strong enough. Where did it fail, was it the base plate area that broke? How did you do the bolt inserts?

I did printed usbox in pla-cf.

I think Indid not use enouth fiber layers, and also no wood or fiber stringer to connect both sides together and make a beam.

The layup has been delaminating from the foam, I stopped using on the last session as it was close to failure.

I will try another round of renforcement.

Weight is now 1.5kgs already ![]()

1.5 kgs isn’t bad?

Gong kluber is 1.7, slingshot dwarfcraft 2.7, Axis tray 2.15 etc😀

1.9kg with latest renforcement ![]()

Added a stringer (cf+cardboard) in a slot of the underside, going all the way to the top layer.

Added another layer of CF on the bottom.

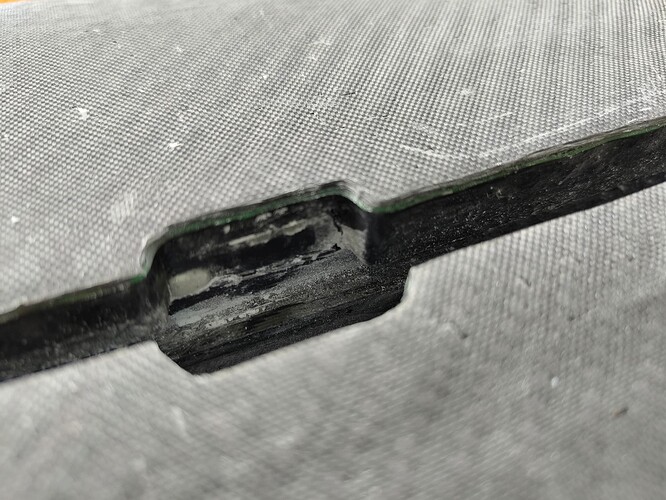

Then I noticed the printed usbox were broken ![]()

Now I filled UP the broken usbox with PU mastic and will drill trough for 4 holes.

Printed board is starting to feel like a simpler solution.

I think my mistakes were the too low density pink foam and the printed usbox.

Do you really need the adjustment on such a small board? I mean, it will not get on foil from sinked anyway and the pumping position is always the same?

yes, adjustement is really not that usefully . Wasted a lot of weigth budget on those printed usbox.

Cf board sits at 2.2 kg with pad, and works for at least 10 sessions now. Hit some rocks pretty Bad when learning rock start, happy to do it with a prototype board I do not really Care about.

Printed board is shelved for now.

Sealing option - Dichtol - it penetrates the plastic. There is a video about using it for a miniature submersible vehicle.