Hello all,

I have been thinking and working a little on a project, to make a fully 3D printed foil pumping board.

nowdays you can buy purpose perfect boards for 400, so why bother?

I am always looking for engineering challenges and I like 3d printing.

I now on the V3 of my efoil assist with 7s4p 21700 and 6374 and 6384. My goal with this system was to ease my pump foil journey, but now i’m a little stuck on that front. so I got a new better foil, a 25l surf foil, and that should spice the pumping and faux drive game.

in the meantime my local scene is more about pumping, and I’m about engineering, so why not spend hours and money on another DIY pumping board.

I have seen a very nice article about a printed core and glass/carbon layup board here :

Also, some guys in france are puming with a set-up consisting of two carbon tubes and a thin platform+bags for buoyancy.

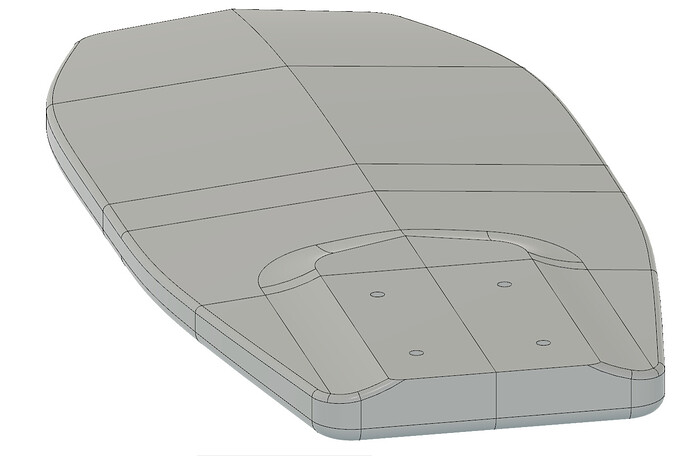

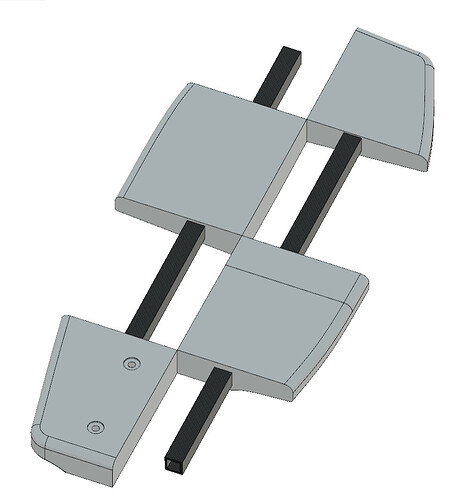

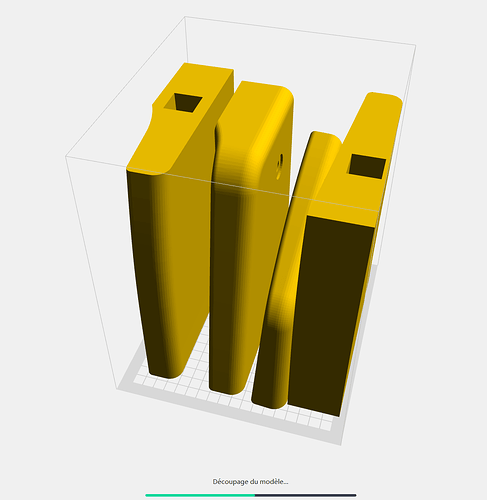

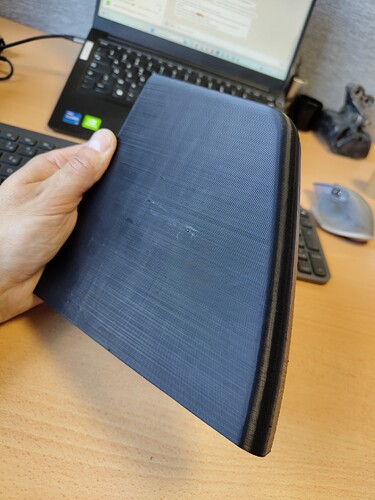

My goal with this project is to make it replicable by any hobbyist with a printer and good printing abilities in the world. Most machines are capable of 220mmx220mm, so I set my blocks at 215mm each. By 8 blocks we can make a pumping board.

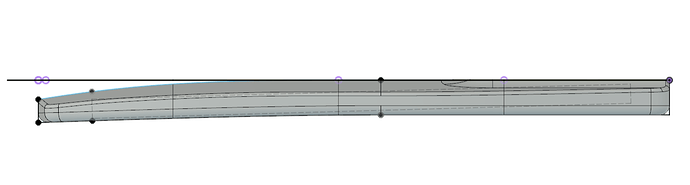

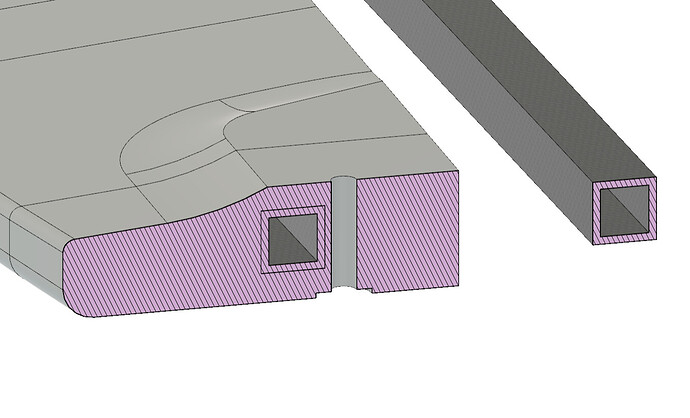

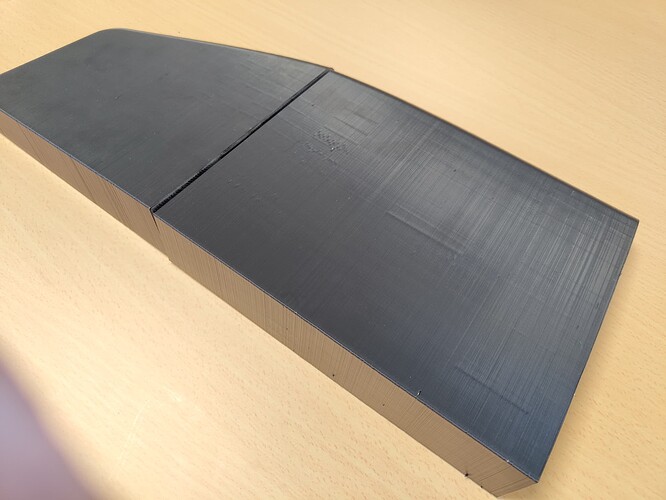

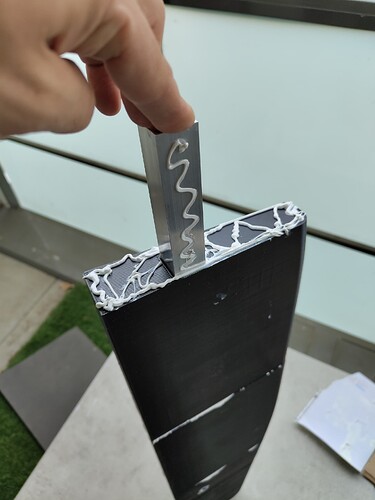

Then some rocker, fitting a angled 700x25x25mm square tube :

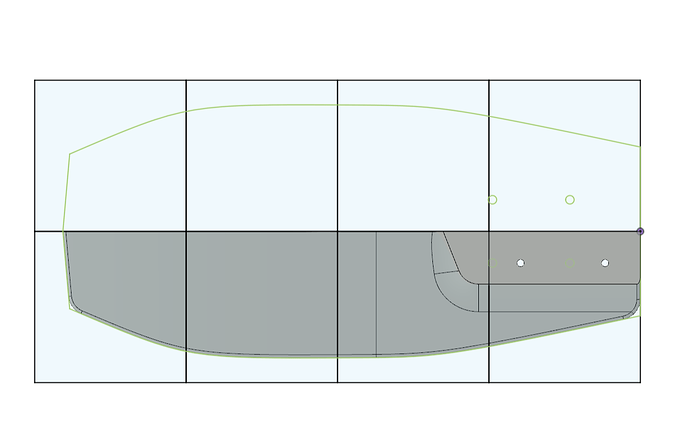

some shape for the underside :

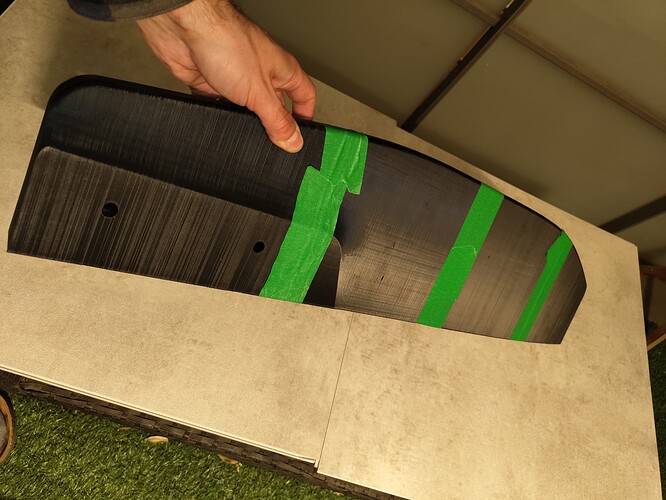

So I was thinking about carbon tubes for main rigidity and positioning the different blocs.

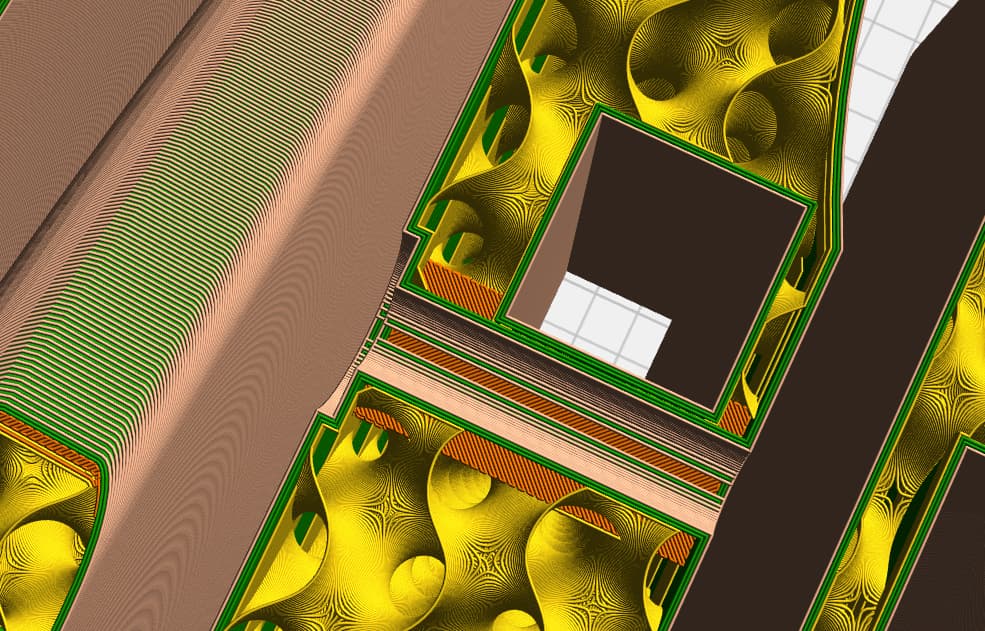

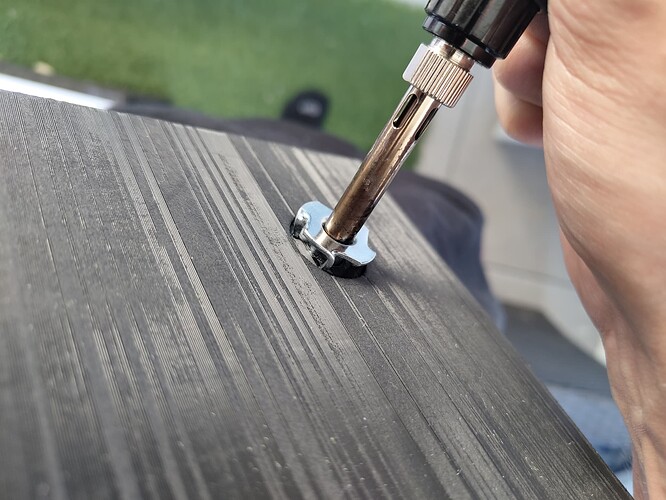

Mast screws as close as possible as the tubes to reduce loads on the plastic :

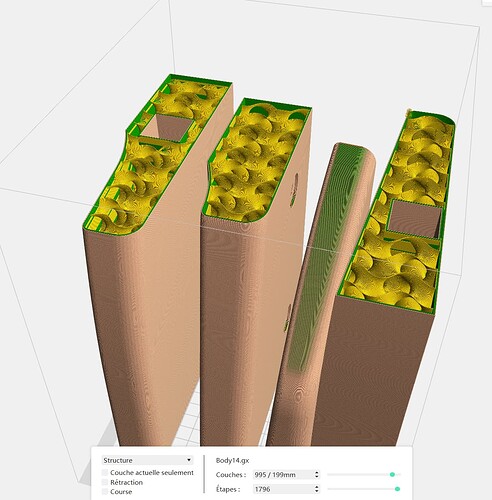

Quick verifications looks like I can have the 8 board parts for around 1.5kg, with low infill gyroidal.

the danger zone

That’s as far as I got so far.

Next :

- Lateral interlocking of the blocks, maybe just normal wood dowels

- Infill optimisation to have closed cells

- printing tests and material selection

- find motivation for 60-100 hours of printing for a probable first failure after numerous print failures

- find out if varnish or epoxy coat is enough to seal the print

Do you think it can be done? any recommendations?