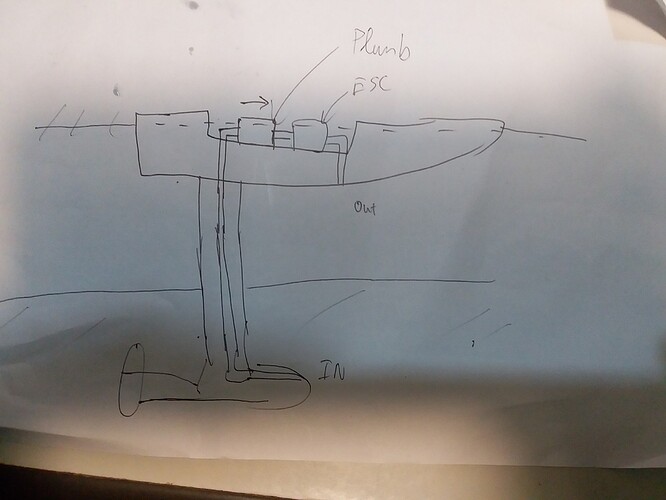

Please help me. I want to know how can the plumb take water from altitude(height)?

In fact does it always work continuously?

As long as your board is moving forward and the water line is open to the direction of travel there will be plenty of water passing through.

Can you show me some photos or videos in that the water through out the board from height

Could you please explain more about the potential for spikes … and frying the ESC with long battery wires? I would like to have the ESC in the mast which would require running 1m power cables between battery and ESC. I take it going to 8WG won’t help? Therefore, what capacitors and where? Thanks …

Hi @pacificmeister, I have a quick question: what is your opinion on a 150a esc using it with two 22ah lipos in parallel? (22V) Will it drain too much current for my SS motor (the same you used for your first documented prototype, but without gear ratio!)

I would be glad to hear from you.

Kind regards from switzerland

Hey, I am having similar design with my VESC against aluminium plate. How would you recommend to apply thermal paste as I have gaps between the fins of my vesc? Should I fill all the gaps with thermal paste?

thanks!

Mill them down. 20 char

i see, i could try to remove them with a dremel

It should be as flat as possible for good heat transition.

Those fins on the esc case are really meant for air cooling (or convection cooling). There are even holes there for mounting a fan. For using conductive cooling, in this case metal to metal, you want the surfaces to have as much contact as possible. Thermal paste is really just to fill microscopic imperfections between two “flat” surfaces to eliminate small air gaps.

You could try to dremel it down and get those surfaces flat, I think that sounds like a lot of work.

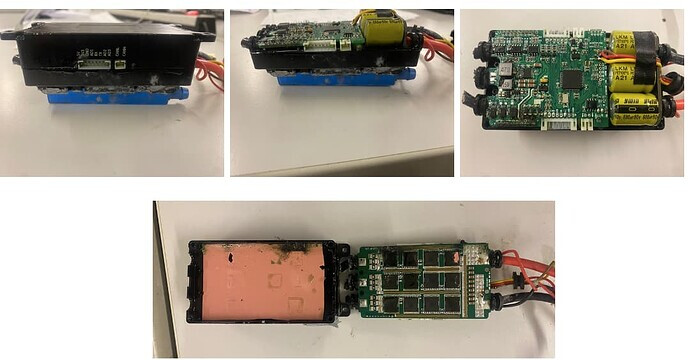

I think a simpler approach would be to just get rid of the case entirely. Put the naked esc against your aluminum surface with thermal paste, maybe a spot to glue to hold it in place. Then place a junction box (or 3d printed box) with the bottom surface cut out over the esc. The box can be glued down onto the aluminum surface, holes with cable glands can be added. This approach has been used on some of the Fliteboard adapter plate builds

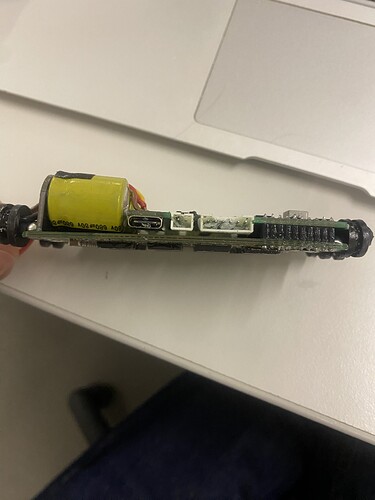

This is what mine looks like:

pls dont post on a thread that has been dead for years. sends hundreds of ppl emails.

really nice!

Here are photos of opening my last VESC that died from water. Following your approach: on the 4th photo, thermal paste should be applied on the 12 black squares ?

Or you can just change Tracking to Muted and you won’t be notified at all about new activity in a thread.

The black squares are the mosfets, they will generate most of the heat that needs to be handled.

It seems that this esc is a single PCB that is double sided. This design is harder to keep cool than some of the two pcb stacked designs, at least in an efoil application. In the thread I linked above the esc is a Flipsky 75200, it has the two layer design with all the mosfets on their own pcb on the bottom and there’s an integrated aluminum plate. That integrated plate is what gets pressed onto a larger cooling plate with thermal paste. You could still press your esc against a larger cooling plate. Maybe better to reuse the pink silicone cooling pad that came inside the original case. You will need to figure out some way to have the esc fastened down and pressed against the larger plate. Maybe small brackets, maybe small screws passed through the holes in the pcb.

it’s nice that Flipsky does that, better than Maytech

Cooling pad is better than thermal paste on the mosfets?

I think the pad might be better in this case because it may offer more protection. I doubt pressing mosfets directly onto metal with paste is a good idea. Could damage them and cause a short.

okay i see thanks a lot!