Do these newer 65161 from flipsky need this treatment? I will be using mine in fresh water only.

Hi together,

Since this topic doesn’t seem to be dead yet, I also started a test series:

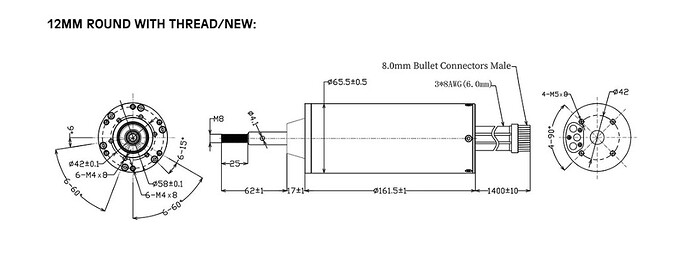

I cut 3x30mm cables from a brand new Flipsky 65161.

Test criteria:

- Diameter change

- overall optical apperance

- bending at 180°: cracks / insulation failure

Test environment:

- Climate chamber @65°C constant (150°F)

- One Sample each in Mineral Oil, CorX and ambient

Time between measurements

6 days each (simulating 3 Months* @ 25°C / 75°F)

Total 10 increments (~3years sim.), or until all samples are destoyed.

Next measurement: 08.03.2023

Edit: There has been a loss of temprature at the climatic chamber, test will be extended to 09.03.2023, 17:00 to achieve 3 months

*This goes back to the RHT Rule, stating a doubled reaction speed for a temperatue rise by 10K. However, at big temperature deltas, this could get inaccurate.

Great effort

Might be interesting to add a pull/tearing test on the insulation as the final test on the samples

Found this thread today and got a bit worried. I’ve had corrosionX in my 65161 now for about 3 years. I have opened and checked the motor for leaks after every season. Looks good for now. Should I expect something dramatic to happen soon (leakage, loss of insulation resistance…)?

I dont think so. Many people have CorX without problems for a long time.

And actually, if it already ran fine for 3 years, I would not expect anything in the near future.

But that’s exacty why I do this test. From some people you hear “It runs fine for years” and from other you hear “Your cables will become britle after some months”

The test result is probably unique to the cable you test so it’s good that you test one of the most common motors.

I’ve had ebay silicon insulated wires that lost all color and got brittle in only a year just from the UV - and we don’t get a lot of sun so quality sure can vary a lot.

Will follow your test. Thanks!

Test results see below

Interested to see the results of this as oil can commonly diffuse the compound plasticizer causing wire insulation to crack. I will be running my 65161 in salt water and have been considering filling it with corrosionX as many others have done. Only thing holding me back is I am scared disassembling the motor could damage the seals causing more harm than good.

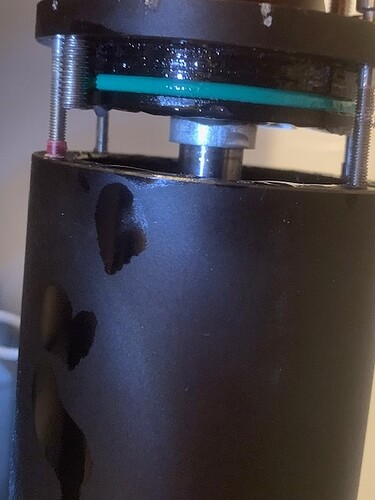

I found that quite easy to do.

I made a small wooden plate. With this, you pull the top plate including the whole rotor to the top with 2x M4 threaded rods, using 4xM3 screws in the outer ring to push against. Only high enough to make a gap.

With this method, you dont move the seal from shaft to housing, only the seal from plate to housing which is just a normal O-Ring.

To reinstall, put a screwdriver through the hole and push+turn at the same time.

I filled about 100ml in it, although, 50ml would probably be enough (by weight thats 88g = 100ml)

Test results:

| Sample | Test criteria | 3M | 6M | 9M | 1Y | Pass/Fail |

|---|---|---|---|---|---|---|

| Ambient | Diameter | 5.95mm | 5.93mm | 5.95mm | 5.92mm | Pass |

| Bending | No tearing | No tearing | No tearing | No tearing | Pass | |

| Mineral Oil | Diameter | 6.01mm | 6.00mm | 6.02mm | 6.01mm | Pass |

| Bending | No tearing | No tearing | No tearing | No tearing | Pass | |

| CorX | Diameter | 5.95mm | 5.91mm | 5.91mm | 5.92mm Pass | |

| Bending | No tearing | No tearing | No tearing | No tearing | Pass |

Images of Samples:

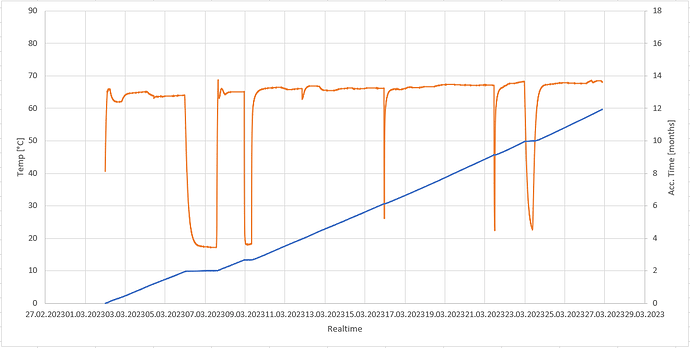

Temp Profile and acc. time:

I will now enlarge the time between tests to 1 Year simulated. Next results at 14.02.2023.

Another year has passed

Still no damage.

| Sample | Test criteria | 3M | 6M | 9M | 1Y | 2Y | Pass/Fail |

|---|---|---|---|---|---|---|---|

| Ambient | Diameter | 5.95mm | 5.93mm | 5.95mm | 5.92mm | 5.96mm | Pass |

| Bending | OK | OK | OK | OK | OK | Pass | |

| Mineral Oil | Diameter | 6.01mm | 6.00mm | 6.02mm | 6.01mm | 6.08mm | Pass |

| Bending | OK | OK | OK | OK | OK | Pass | |

| CorX | Diameter | 5.95mm | 5.91mm | 5.91mm | 5.92mm | 5.96mm | Pass |

| Bending | OK | OK | OK | OK | OK | Pass |

I will let it run to 3 Years, then I will do destructive tear strength test.

If someone has access to a professinonal tear strength test machiene, contact me

See you 08.May.2023

Hi everybody, Final results are here!

But first some statistics:

The test ran from 2nd of March, 0:00 until 9th of May, 16:00

Consuming 20W of average power to heat the chamber to 60~70°C.

This means 1.648 hours of runtime and 33kWh of energy consumed (about 15 Euros in Germany)

And here are the results:

Diameter and Bendability:

| Sample | Test criteria | 3M | 6M | 9M | 1Y | 2Y | 3Y | Pass/Fail |

|---|---|---|---|---|---|---|---|---|

| Ambient | Diameter | 5.95mm | 5.93mm | 5.95mm | 5.92mm | 5.96mm | 5.92mm | Pass |

| Bending | OK | OK | OK | OK | OK | OK | Pass | |

| Mineral Oil | Diameter | 6.01mm | 6.00mm | 6.02mm | 6.01mm | 6.08mm | 6.13mm | Pass |

| Bending | OK | OK | OK | OK | OK | OK | Pass | |

| CorX | Diameter | 5.95mm | 5.91mm | 5.91mm | 5.92mm | 5.96mm | 5.98mm | Pass |

| Bending | OK | OK | OK | OK | OK | OK | Pass |

Images after 3Y:

Tear strength

First I took all the copper out of the cables:

(left to right: Ambient, Mineral, CorX)

My test setup maxed out at 6.5kg of pull force on all the insulations. So I also decided to do a test, where I place a sharp knife on the insulation and push on it, first across the insulation, then down the middle of the insulation.

| Sample | Pull Strength | Knife across | Knife middle |

|---|---|---|---|

| Ambient | >6.5kg | 700g | 250g |

| Mineral Oil | >6.5kg | 500g | 190g |

| CorX | >6.5kg | 400g | 130g |

While the insulation does feel a bit softer on the CorX, I also wonder if the lower knife force may just be due to the residual oil lubricating the cut… Not sure about that.

All in all, I would say both Mineral Oil as well as CorX will not damage the cables in a significant way in a significant time while minimizing the chances of rust and stuck bearings.

Yeah science !

thank you for this work

Great work - Thank you!

Thank you so much!!!

Hi @ludwig_bre following your brillant idea, I design a quick part call ‘65161 oil filler’ to help everyone to do this task. Here the thingiverse link Flipsky (new) 65161 Mineral Oil Filer Tools by macfly1202 - Thingiverse

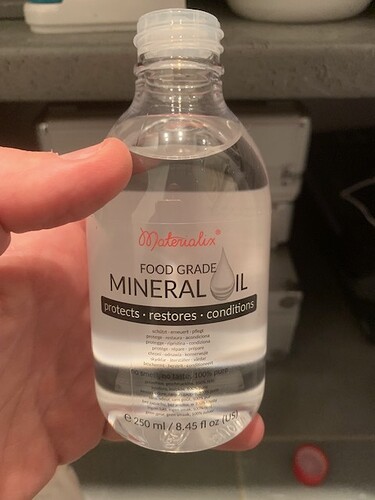

Like @jkoljo advice, I choose l Mineral oil pharmacy - he recommand 80ml approx But I find with syringe 80ml was too much so I remove a little to have approx 70ml. Everything I use is common M4 x 32 to push and rest of threaded rod for the pod for pulling. Go slowly, left; right and it goes up very easyly. After just fill oil. Then clean holes and close it back. ![]() Thanks again @ludwig_bre for this brillant idea that don’t move the ceramic part.

Thanks again @ludwig_bre for this brillant idea that don’t move the ceramic part.

I have this new design hole:

In the e-bike world some people fill their hub motors with a ferrofluid (so it sticks to the magnets) to try and provide better cooling.

I wonder if filling motors with oil would have a secondary effect of helping with cooling as well?

Has anyone noticed improvements?

Yes, it helps. There’s the excellent thread on motor cooling by Justin_le on endless sphere with test results, from memory he also tested oil filling without ferrofluid.

I think for us it doesn’t make sense though since filling=inrunner and inrunners have excellent cooling naturally from the water. If you want to make an enclosed outrunner then it would be a good thing.