Dear all foilzoners,

I wanted to share my latest Efoil build, for others to seek inspiration and to guide DIY’s - like myself, who wants to build their own Efoil.

Specs and components:

- Board dimensions: 1600x600x120mm

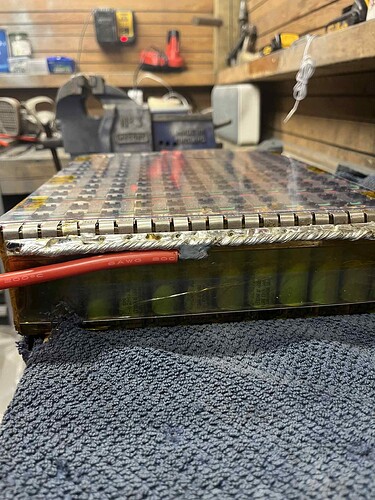

- Battery: 14S12P 18650-25R Samsung litium ion. 1,5kWh with 100A fuse. 2 layers of 0,2x8mm pure nickel strip. 6 AWG wire from battery to VESC.

- BMS: 100Balance 40A 8-17s with active 1A balancer.

- VESC: MakerX Go-FOC 300 4-21s and 500A Max battery, 250A Max motor. With bluetooth module for data-logging. (This VESC might be overkill, but it ROCKS!!)

- Remote: Sprintend Uni1 2,4GHz remote using UART for telemetry.

- Motor: Flipsky 65161, 120KV, 6kW (round with thread shaft)

The board:

The Efoil was made from EPS insulation and cut using a hot nichrome wire mounted both parallel and perpendicular to a flat table. If available, I would choose XPS, as EPS soaks a lot of epoxy later. By printing a 1:1 template from fusion 360 on multiple pieces of A4 paper, it was easy to guide the wire cutter against the template.

After cutting the rough shape, I used a handheld router to carve out the insert for the hatch and the wooden piece underneath the board, where the battery, VESC and mast later were mounted to. As sharp edges are difficult to warp fiberglass around, I cut a fillet on all these edges filled them with thickened epoxy before glassing. I glued a 12mm plywood board from birch to the underside, to give the board extra strength where the mast mounts to the board. Using a orbital sander and grinder with sanding discs, I shaped the board to the final shape. Before glassing I added solid 3D-printed PETG block, where woodscrews later can be used to mount hatch, battery etc. Don’t use PLA, as it will soften when exposed to the heat of the sun. When glassing to an edge, I found it easier to do one surface at a time. Although more time consuming, it is the only way to get a sharp edge without vacuum bagging or infusion. It is very important to prep the surfaces with low grid sandpaper and wiped with IPA where cured layup meets wet, as this bond relies purely on surface adherence and not chemically bonded. After this I could start glassing the entire board. I found from previous experience that 2 layers on both sides with 300g/m2 was insufficient and was easily dented when hitting the dock. This time I used 4 layers (300g) top and bottom, giving 8 layers on the sides where they overlap. This is plenty strong and will last forever. I was using PETG inserts where bolt for mounting the mast will go through the plywood. To avoid water from leaking into the wood, these solid plastic pieces will prevent this. The hatch was made from same plywood, but with small wooden braces to stiffen the hatch. Earlier experience taught me that the hatch must be very stiff, to keep a good seal against the board. I painted the board with a 2-part polyurethane paint made by Hempel (Polygloss in cobalt blue).

Foildrive:

I use a 700mm GONG V1 mast with V1 fuselage and a V1 1350cm2 front wing and 400cm2 rear stabilizer. These were sanded and painted with an automotive 2-part clearcoat or glossy powder coat. The motor is mounted to the mast with a 3d printed motor plate, and a CNC milled aluminum front mount. These are clamped around the mast with a TPU 3D printed shim. The interface plate between the mast plate and the board is also CNC milled aluminum with a silicone O-ring and cable glands. Both were made by JLCCNC.

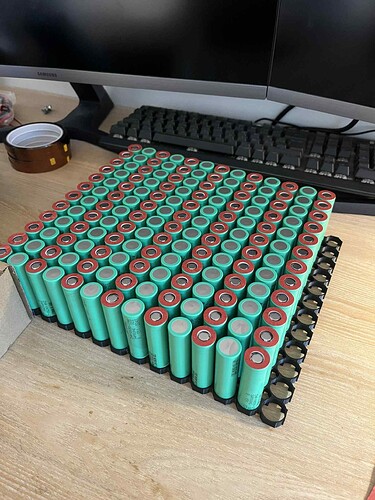

Battery:

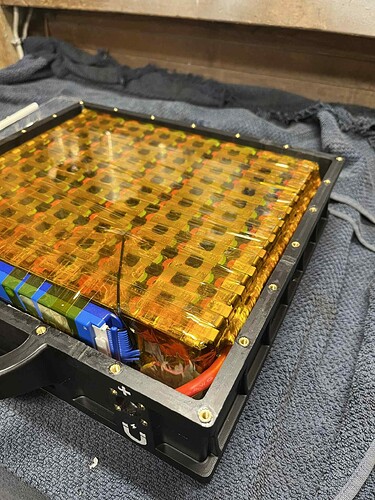

The battery is made from 168 lithium-ion batteries. This gives a 14s battery with 12 in parallel, giving a 1,5kWh capacity at 50,4 V nominal and 58,8 V maximum. It was spotwelded with pure nickel strips. It is important to add a fuse as close to the battery as possible. I mounted the fuse inside the battery, although I guess it would be alright outside too. I used a BMS for charging and bypassed when discharging. Although some prefer to discharge through the BMS, it then requires a bigger and more expensive BMS. I have not had a single problem, and all cells are always ± 0,005V to each other. The case is 3D printed in PETG, with M4 threaded inserts to screw the 2mm aluminum plate to each side. The inside is coated with thickened epoxy and sealed with silicone between the plastic and aluminum.

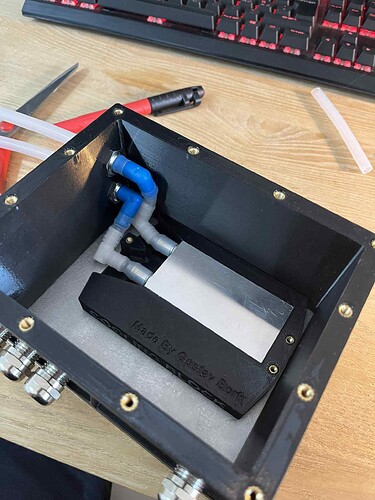

VESC:

The VESC box is 3D printed with thin walls and no infill. I filled the internals between inside and outside walls with thin flowing epoxy, to create a 100-pct. waterproof enclosure. The top polycarbonate sheet is screwed down with M4 bolts and nuts with a 2mm silicone seal between. The VESC is cooled with a single water cooled heatsink, which works perfectly and never leaked.

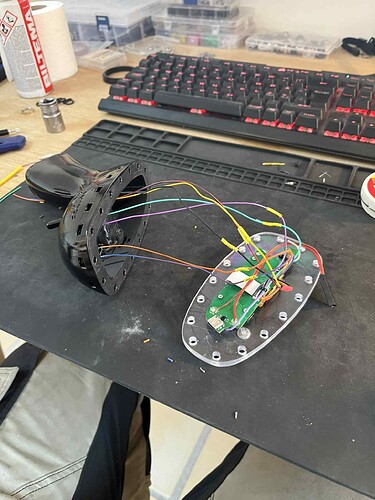

Remote:

The remote is made the same way as the VESC box and has also never leaked. The design is one I found elsewhere but redesigned it to have thicker walls and to fit the remote PCB. By using a hall effect sensor with magnets outside the remote, the remote stays waterproof. This uses one single lithium cell from the Efoil battery.

If you have questions or suggestions, feel free to comment. All STL and STEP files is also available if needed. Good luck:)