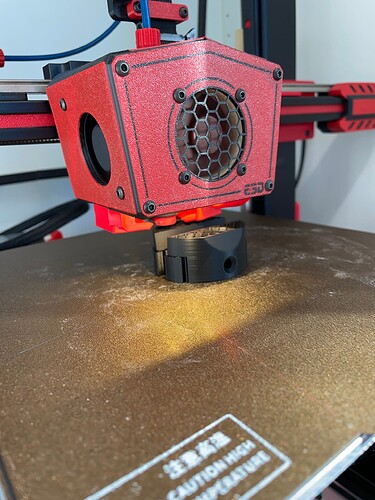

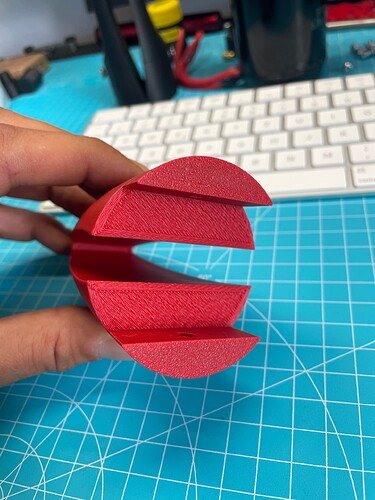

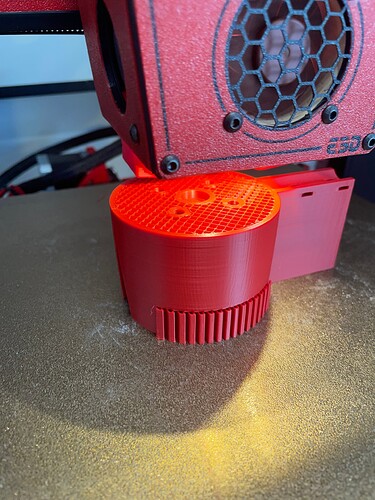

I potted my stator and rotor with thermal epoxy.

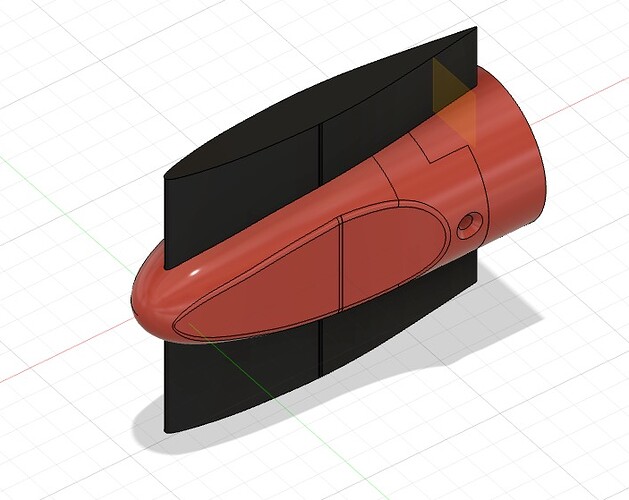

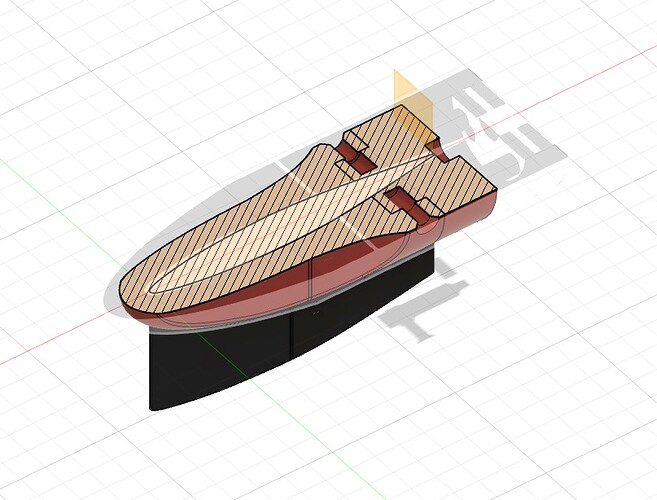

Looks great! Which epoxy did you use? Are those 3D printed sleeves?

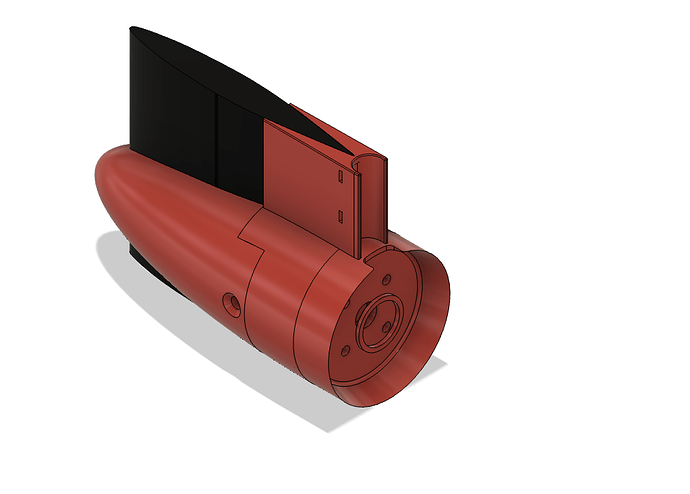

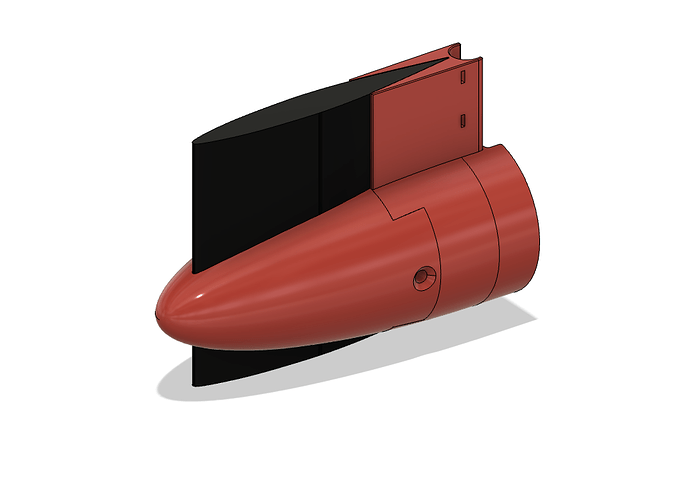

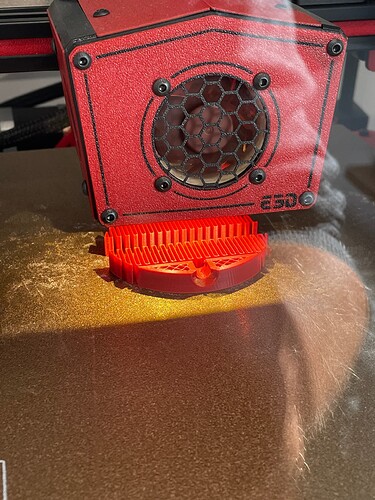

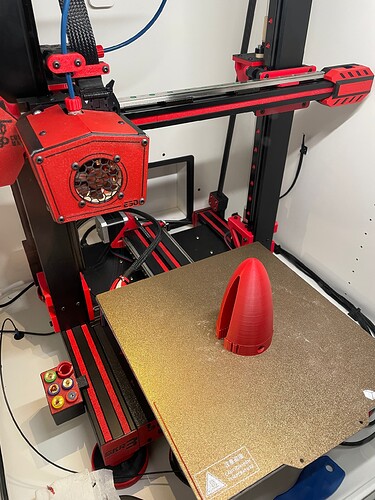

Thank you. Yes this are printed sleeves.

Epoxy is from: MG Chemicals

In the next few weeks we will continue with the battery and electronics. Pictures will follow.

When my project is finished I will publish my CAD data on printables.

Your Stator might die due to overheating. Potting it completely is not good concerning heat dissipation.

Just some brushing the EP over the metal parts to prevent them from corrosion is enough for the outrunner motors

Foil.Drive or the Saite motors are also completely filled with thermal epoxy and have no problems! We will see.

Just a note: Justin at endless sphere did some tests with thermal epoxy potting, there was actually a small benefit when the best thermal stuff was used.

Anyway, you’re right, we don’t really need it since the cooling is excellent on set outrunners also without it and worse when potted with normal compounds.

Looks great, can not wait for you to share the files!

What files are you needed?

Hi Markus,

First of all, I am glad you put all detailed here including many pictures.

As your hobby 3d printing, I will ask you some questions  :

:

- Is it practical to 3d print the box - the enclosure for all the electronics? I saw methods for waterproofing 3d printed stuff…

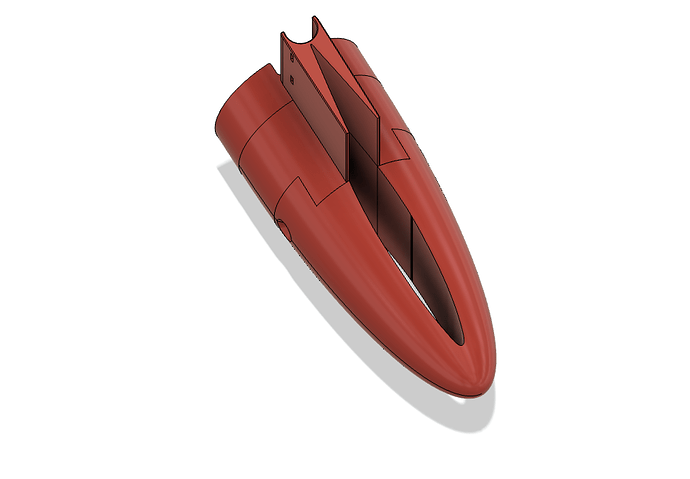

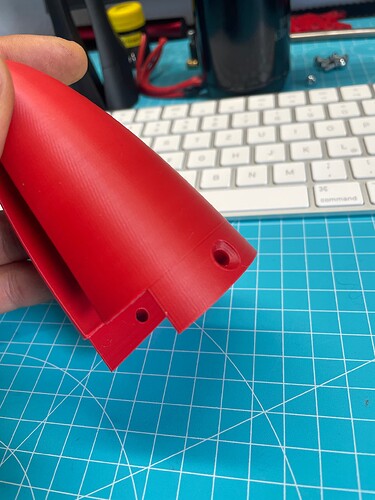

- The motor pod - do you intend to waterproof it? Like maybe it will collect water and becomes havier… BTW have you seen a like tesla door hand motor pod? - connect without tools…

- Why didn’t you 3d print the propeller?

Thank you.

Regarding 1:

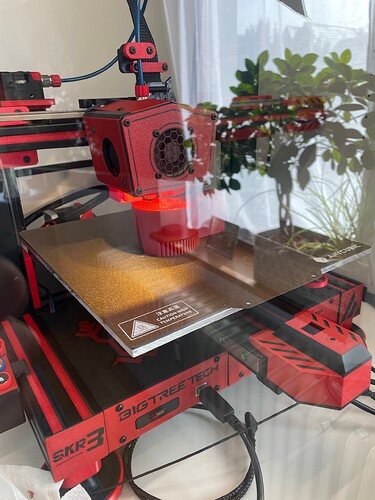

Yes, it would be possible to print the box. But it’s far too complicated and doesn’t have enough stability. And my printer would also be too small in terms of print space.

Regarding 2:

Since I printed the pod with 7 wall lines (0.4mm x 7), no water penetrates through the PETG. I think a coating is not necessary.

Regarding 3:

I have concerns about the stability and longevity of a printed propeller. In addition, the Fold Prop from Propellerking is of excellent quality.

I would buy the Fold Prop again at any time.

Thx to @superlefax

7 wall lines - thick indeed

I read this:

They suggest to:

- PETG

- more walls

- overextrude

- higher temperature

- wider nozzle

- lower layer height

How much infill did you do?

You think PETG is strong enough? There is no need for something like PC-CF ?

I am interested to hear what concerns do you have regarding stability and longevity of the 3d printed propeller

The stability of my pod should be sufficient with an infill of 40%.

But I will still print a pod in ASA-CF.

When my system eventually works in the water, I will test a printed prop.

Many users also use printed props.

You have the enclosure for ASA ?

Do you think 8s3p is enough torque? Why did you decide on 8s and not 10s or 12s. The higher, power transfer should be more efficient, no?

BTW

I composed here info about 3d printing and materials, I would be glad to receive comments or PR, you can write them in the comments on the page or direct:

this topic will be updated as well:

https://foil-assist.vercel.app/parts/motor/motor-mount

Yes, I have an enclosure for my printer.

At ASA I go to 45°C in the printing room.

I chose the 8S3P setup for myself. That should be enough for me.

But it is also the first building for me.

Possibly I can switch to 10S later if I don’t have enough boost.

Hi Markus, love the highly detailed description of your work. Will follow your progress. Keep up the good job!

Hi Markus, great build! could you please share some pictures of your battery build? thank you!!