They work just great! I use 3 since 2018 and still perfect, with XT150 and awg8 cables. Takes a minute to plug and unplug and are a little bulky but they are reliable and cheap. Got 4 of them on amazon for less than 15Euro.

sat_be great work!

can you share the CAD data?

cheers

No problem, here’s the Fusion 360 Link: Fusion

Please be aware that they won’t fit out of the printer, they might need some reworking, I used a lathe to make them fit.

O-Rings 13x1mm: https://www.aliexpress.com/item/32904189270.html?spm=a2g0s.9042311.0.0.27424c4dLIkA3j

Threads: Cable glands: PG7, d12.5x1.27mm

AS150 connectors: M9x0.75mm

I’ve designed some similar waterproof connectors for my motor wires. They will be submerged in water when starting so I have a few questions:

What would happen if water got into the motor wire connectors? Would it short circuit the ESC? I assume water would need to get into at least two of the connectors to create an electrical path.

Is it ok to use silicone grease where the connectors interface with each other (gold to gold) or will the dielectric properties prevent a good contact even though it’s a tight fit?

Does anyone ever use silicone grease in the battery contacts to prevent arcing when connecting the batteries? If I have a switch filled with grease would it prevent arcing inside the switch? Would it lower the amp rating of the switch?

Is XT150 ok to use for motor wires or should I be using AS150 instead?

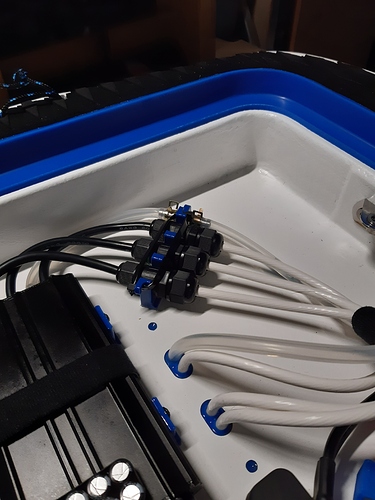

Here is my connector design:

They look good, I built similar connectors to connect the ESC Box to the battery. Although I used AS150, I think XT150 are ok for the motor as you would not connect them when the ESC is switched on, so no spark. Hard to say what happens when 2 connectors get in the wet. In fresh water probably not much, in salt water it depends on the distance between them. I only used silicon grease to lubricate and seal the connector housings and seals, not the contacts itself. I prefer metal on metal for contacts.

These are very similar to the ones sat_be made except for Xt150. I used the plastic cable glands though. You mentioned the plastic ones have leaked on people… I have two brands and one brand leaks and the other doesn’t so I will use those. But, what are the consequences if they do for the motor wire connection? Will it fry my VESC?

How do you waterproof the cable gland to 3D printed tube thread ?

IMHO, to protect my ESC, I wouldn’t use connectors in such conditions unless I am 100% sure they don’t leak. I would leave two identical samples fully submerged 2hrs in 5cm of water and see what happens then repeat the test 24hrs later.

I would insert a small piece of school blotting paper in the tube to detect any water drop.

I use these. Perfect for a xt150. Bit tight for a AS150 but could make them work if you had to. You just take out the connector bit in the middle leaving room for the xt150.

Compact at 54mm x 17mm and IP68 rated.

That is one hell of a tidy setup! well done

I just thought the same. Why is mine such a mess

The cable glands are sealed with the gaskets they comes with. They fit in a recess to keep them from squishing out which allows me to tighten them really well. The print quality is really good and high resolution to insure the o-rings seal good.

I could fill them with silicone grease. Part of my initial question is if it’s bad to get grease on the gold connectors or is the contact firm enough to not increase the resistance?

I will test them under water and inspect for moisture and if it looks good I will foil with them. I think a good line of defense is the fact that two of them would have to totally fail to cause a short, right? Would it help to spread them apart an inch or two? I will be using it in fresh water.

Yes, a moisture test and you’ll be set.

I would say like @sat_be, metal on metal, electrical contact should be as direct as possible, the question being how much grease is not too much… how to determine the lower limit ? Another point is if/when your contacts get contaminated, how do you clean them up afterwards ?

Hey Michion, your second build looks really interesting. Would you mind sharing some pictures in your build thread ? Seems like you’ve built your electric box and its gasket differently from your first board…

@mattgalic’s are a bit larger: 23mm x 92mm for 5-10mm cables (and a bit cheaper)

https://fr.aliexpress.com/item/33002197500.html

May I ask what is made off the blue staff around the hatch ?

Those are 40mm longer, so quite a bit bulkier. I prefer the more compact version.

The blue seal on the hatch is moldstar 30.

I’ll update my build thread to stay off this thread.

how did these connectors work out?

They work quite well, but I needed to do some rework on the lathe to make them fit.

I use normal xt150s with silicon grease in them on my efoil, no issues. I fill them so the grease is squeezed out when connecting creating about 2cm wide grease seal between inner and outer connector shell.

I think waterproofing connectors is not super critical at least for the motor wires if they are kept behind a tamper shield. Off course they should be permanently protected and i really like the solutions in this thread but as a temporary fix a greased xt150 will do.

AS 150 fits well if you shorten the pins by cutting off the threaded part (2-3 mm). I also used those 54 x 17 mm connector housings.

Can you share the stl files?