Try removing 3 holes on the side and get a quote again.

You can drill them by hand afterwards.

I did. It’s about the same price.

I think it’s the height what makes it pricy.

Build the walls for the box from Acetal which could be machined on a hobby cnc (if you have one). The walls don’t provide any structural strength so could be a number of materials just bolted to an alu base for heatsink.

Unfortunately we do not have a CNC, but I was thinking about 3D printing the “walls” with PETG and filling the printed box later with potting.

Heatsinking will be done by the baseplate, the big mast underneath it and water running through the CNC’ed channel

Another method is to print, then take a silicone mold of the print, then use a hard urethane molding resin into the silicone mold. Way stronger than a 3D print…

Cross link:

I continue to look for a good used 100 litre Fliteboard as I’m interested in replicating what you and others are doing.

I’m asking about the water channel aspect of what you are planning. A few questions:

Why do you feel that the plate needs this?

How are you planning on getting the water into and out of the channel in your build?

Hi.

The water channel is definitely 100% not needed.

My dad and I did some static testing, and had the throttle wide open (WOT) for around 5 minutes.

The max temperature we measured was 38c

This is with adopter plate version from @vincent where the FETS are touching directly the aluminium plate. (not mounted in the box as @MBard did.)

We later did some real eFoiling testing (moving), and had again absolutely no heating issues.

We ordered both @vincent and @MBard from PCBway as this was for us the cheapest way to get it CNC’ed.

This winter we might do another Fliteboard setup, and use the “not used” plate to compare things.

- So… How does the water channel work (my theory)

You will need to drill a small hole in the nosecone of the motor mount.

Because of forward motion and pressure buildup, the water will be pushed up through one of the channels in the mast.

The front water channel in the place lines up with the front channel in the mast, so the water will enter here. (need to drill a small hole in the Gong mast plate)

The back channel in the plate is just next to the mast, and water will exit here (I believe you will need to drill a small hole here in the Gons mast plate)

Thanks.

I use the water tube method you describe in my current build as it’s simple and in my case necessary as my vesc is not heat sink cooled by direct connection to mast.

It seems most manufactures and a number of builds here are using the heat sink approach to cooling vesc and I’m convinced that it is effective enough without any passive water cooling to complicate things.

Things like the water tube/channel getting obstructed which happened to me just today. Simple to resolve by water hose flushing to dislodge the clump of algae. First and perhaps only time that might happen but I was not AWARE that the temp of the vesc had climbed until end of session when I glanced at my remote. No damage and the temp did not get high enough to approach the limit in vesc but proved to me that the simpler heat sink approach is better if possible.

“The internal size is 305x390x80mm”

You posted this above and just want to confirm that the dimensions are accurate for the Fliteboard battery compartment. I have battery pack already and I think it will fit but the 80mm Height is close for me.

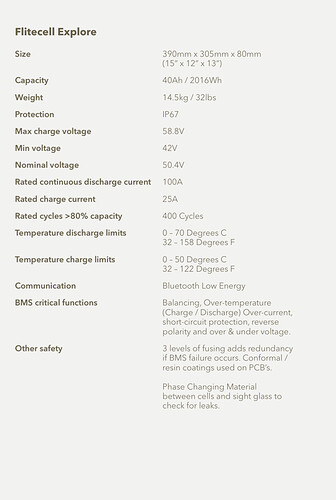

The spec in the user manual for the Explore battery is

These are the same as your numbers.

I’m wondering if the 80mm battery leaves a bit of space to the inside of the lid when the lid is closed and sealed or perhaps Flite uses the battery case to help support the rider weight bearing down on the lid.

I also noted the thickness of the100l board is 118mm which only leaves 28mm for the lid thickness and bottom of board to bottom of compartment to fit in. Must be enough but doesn’t sound like a lot.

I’m on vacation at this moment, and am not able to check, but the lid itself has two struts / stringers running from front to back.

The lid is maybe 5mm thick (except where the struts are) *have to check when I’m back home to make sure.

The lid itself is from what I remember solid (as in not bendable).

We did some watertightness test (without the battery in it), and it did not leak.

However we did this test by holding the board underwater by hand and not pushing on the lid.

It did have a very small amount of water in it, but this happened because of drips running from the lid into the box when we opened it.

Again. As I’m away, I have to double check things I wrote above as this is all by memory.

Kian

Thanks for this, and while on vacation!

Sounds like the lid is very sturdy and there would be no reason for Flite to have it supported by battery. To me that means that there is for sure the 80mm of battery height and likely a bit more so the surfaces don’t rub on each other.

Have a great time!

Came accross this UK supplier site, probably cheaper than Smooth-on:

US supplier: Silpak, California

Mold: Silicone 24usd/lb Tin Silicone Products

Piece: Urethane resin 16usd/lb: RU-575 Clear Polyurethane - Available in Gallons

Motor pods could be made out of hollow rotational castings.

From the Smoothcast site: Smooth-Cast™ Series, Low Viscosity, Easy To Use Resin | Smooth-On, Inc.

Propellers and propeller molds can me made out of urethane too. A molded prop should be much stronger than a 3d printed one + balanced out of the mould.

80,5mm is the max thickness. 81mm is already to big. The Lid is very sturdy, so support is not nessesary

Cheaper, but the shore hardness of Smooth-on is higher meaning less flex in the blades if used for a prop. Ultimately these are great if you have a CNC to cut molds or have a part to reproduce easily. But for one off parts it can be expensive. What I like about them though is that Smooth Cast 385 can also be used in a rough mold and then CNC’d afterwards if need be.

Thanks for the detail info. I’m now confident my battery will fit.

This will also let @kian relax and enjoy the holiday

You are both very supportive!

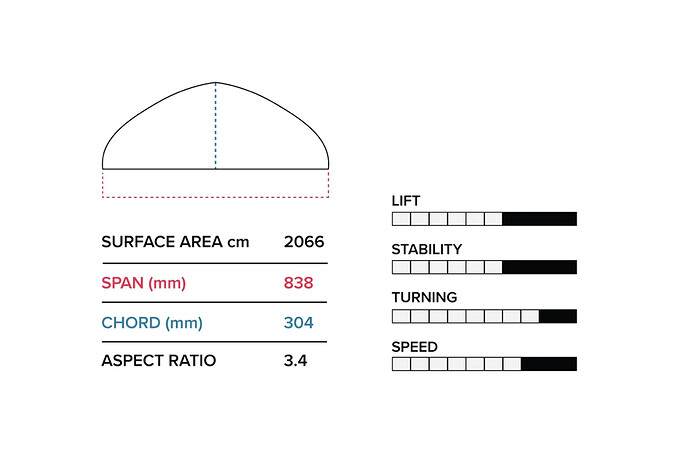

I’m also likely going to use the Gong v2 mast you chose but their foil selection is huge to say the least! I don’t see myself aggressively carving - so I’m considering X-over as I’m relatively new to foiling. Have you ridden them?

I can’t recommend the X-Over unless you weigh more than 110KG and have no balance experience.

If you want a relaxed wing that is relatively easy to ride, Gong’s Curve LT would be it. It’s even on sale right now. Flies from about 16km/h up to 40. It is also, as the name says, suitable for curves. Something for beginners and the family, but offers a lot of driving fun. With Lift it would be the 250, with Flite the 1500.

Thanks. I’m definitely in a smaller weight class than that

As far as balance goes I can fly mostly straight with a few touch and goes and gradually progressing but I’ve only used a very large Slingshot front foil so far so nothing to compare it to. I can’t see myself ever just trying to rip turns but the wind where I am can stir up some pretty big chop and waves so I would like to eventually be able to handle that.

Very useful experienced feedback - much appreciated!

The Curve LT would be a good choice. It is comparable to your Wing, but looks a bit more efficient

I think this is the one you are referencing

https://www.gong-galaxy.com/en/product/gong-wing-foil-allvator-v2-curve-alu-carbon-3/?attribute_pa_taille=lt-en&attribute_pa_couleur=color-blue-en

The LT span is close but surface area is quite a bit less. Again I don’t really have much experience so not challenging you opinion.

If I’m going for a new build I want to change things to make things easier and more efficient but I’m really not after turning ability - I’m into nice comfortable controlled flight - wide turn - go back the other way. Yes swerve around to make it interesting but not into crashing trying to figure out challenging maneuvers.

My uniformed opinion is that I might have started to outgrow my big front foil but am not looking for a substantial change in riding style.