Hello guys

It’s been a really long time I didn’t post on this forum. I started an efoil build a long time ago and got discouraged and never finished it (might work on it again soon).

Months ago I tried wakeboarding in a wakepark and really liked it. So I decided to build my own winch.

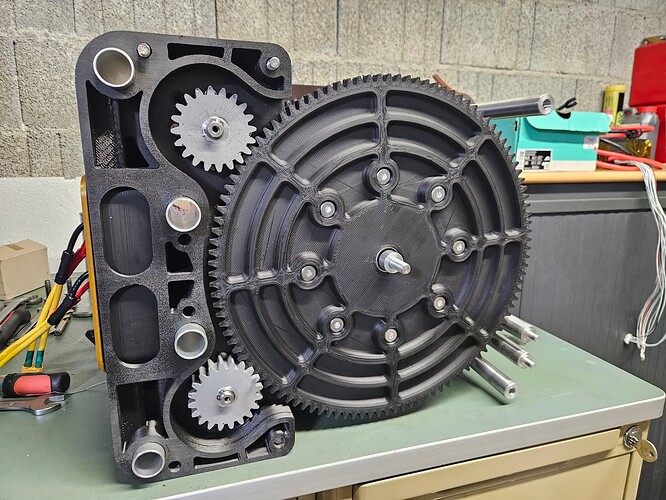

Here is the beast:

A few things I like about the winch:

- I will get less trouble using the winch on the lake. In Switzerland efoil is forbidden on lakes…

- It was much easier to build, no need to do as much waterproofing as an efoil

- you can use it for many activities, you are not limited to water

- Really fun with friends and beginner friendly

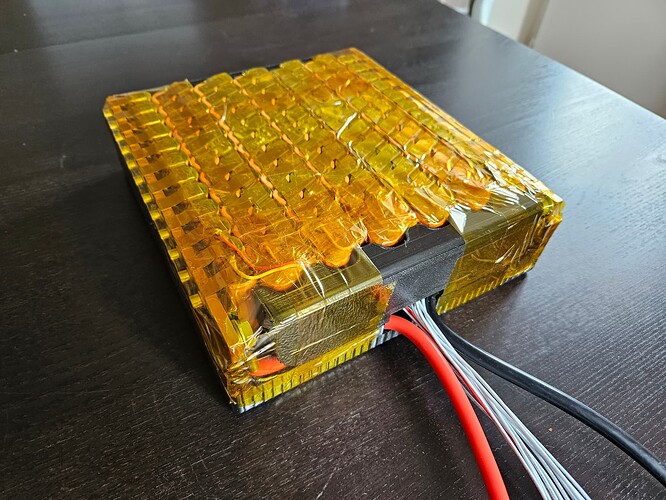

- I can use my efoil battery to power this winch

I made 3 different versions:

1st version was a fail, I used only one 80100 motor that I re-used from an old project. It was not powerful enough to pull me out of the water (I’m 90kg)

2nd version was inspired by the winch from Rewinch (using dual motors and gears)

3rd version is an updated version with belts instead of gears.

Here are the pictures of the build:

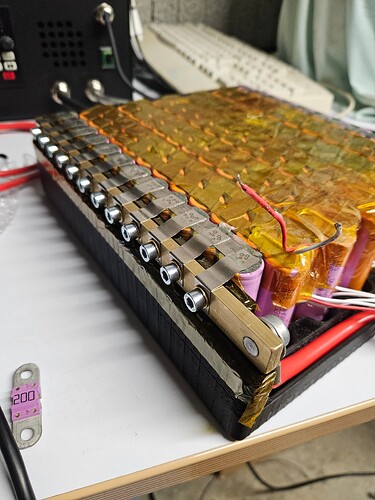

1st step was to build my battery. It’s a 12s12p using Samsung 35e batteries

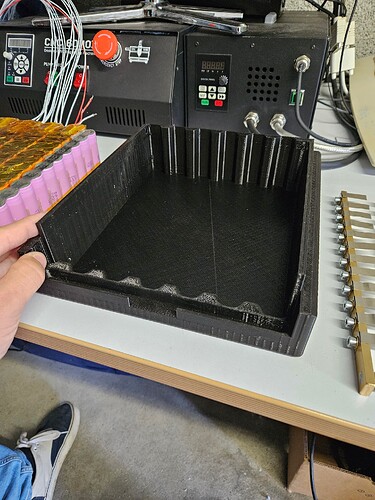

3d printed case :

Spotwelding the battery :

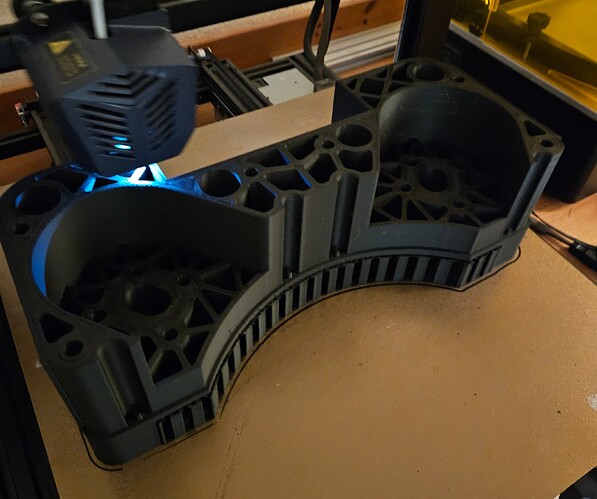

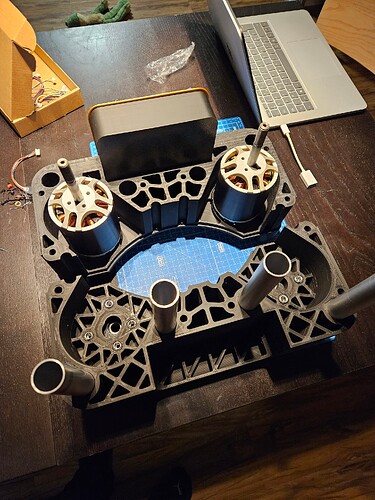

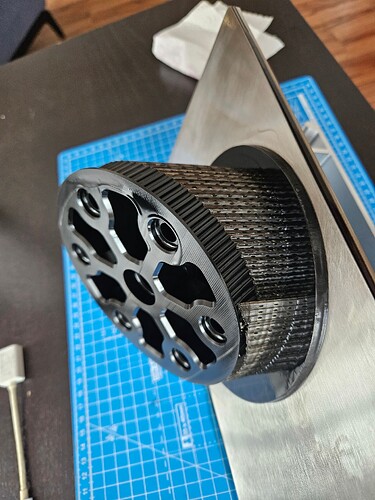

Then I started to build the chassis that holds the motors. Everything is 3d printed and really strong :

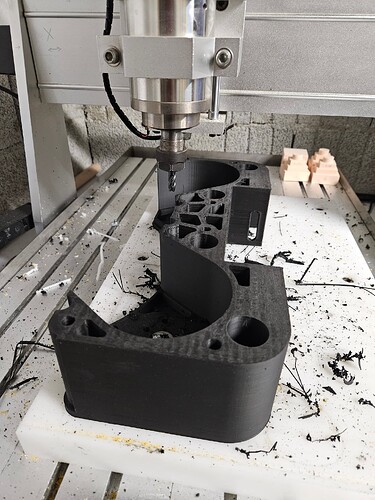

Using the CNC to flatten the top print surface :

Assembling the motors :

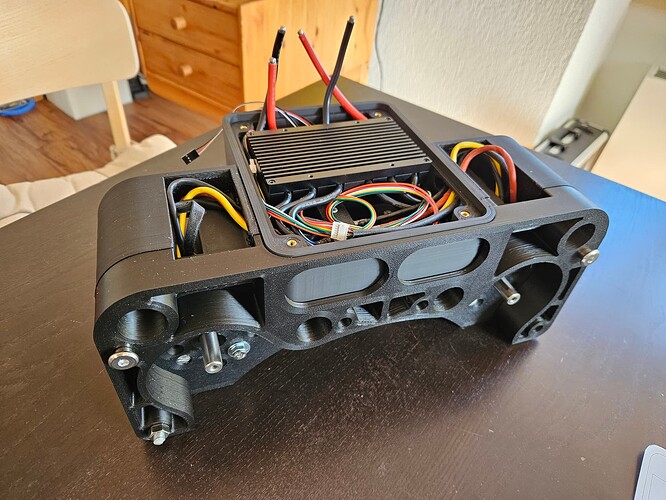

The electronic box :

Fitting the electronics:

After that I manufactured the 2 side plates. I used some wood as it was really cheap and easy to work with (I don’t really care about the extra weight):

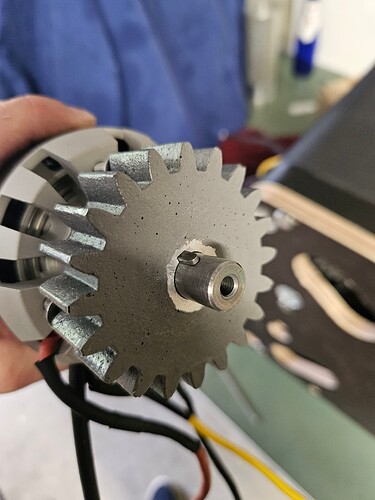

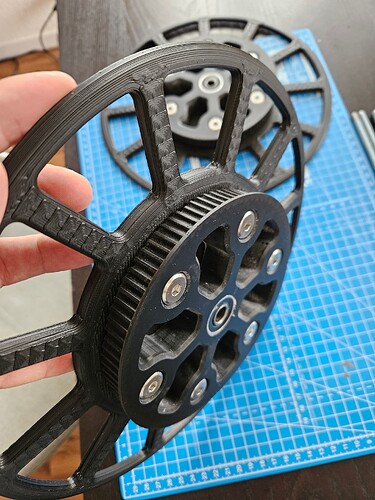

After that I started to work on the gearing system.

I needed 4 identical gears, so I decided to 3d print one, make a mold and use a really hard aluminum charged resin to reproduced them:

Using the lathe to flatten the gears :

Final assembly with the geared spool :

Next I went to the lake to make some test. I quickly realize that the gears were a bad idea, it was crazy noisy !! This is a detail that I didn’t think about while building it and I can’t understand why rewinch is using this system…

So I decided to make a 3rd version, and replaced the gear system with 2 belts.

Resin 3d printing:

Somehow this belt system didn’t require huge modifications and now it’s really silent ![]()

I’m really happy with the build. It has crazy power and can pull me 300m at 32km/h. The battery is a bit overkill, I think my body will be too tired before the battery dies…

The only remaining problem now is the remote sensitivity and the crazy amount of power I’m dealing with. @foilinghopeful had the same problem with his winch from what I read.

Until today I was using a GT2B remote with Current control mode and a 4.0s ramping. (My girlfriend is operating the winch). You have to be really careful when you want to tension the rope before the first pull. I have problem with my shoulder and almost dislocated it the first time we tried the winch, that’s how much power it has…

So I’m calling all the VESC specialist for advices. I think current control is not the good way to go on a winch. The problem is that the winch requires really low current to start turning fast when there is no tension on the rope. So you have to apply really low pressure on the throttle… maybe its better on duty cycle mode or PID speed control mode? I read somewhere that using those mode on a dual setup with motors mechanically linked on the same shaft will blow up my vesc or motors, is that true ?

This is the remote from rewinch :

From this video I think they are controlling their Esc on speed mode, am I right ?

Next step for my build :

- Better VESC configuration for smooth operation (please help)

- I received a flipsky VX1 yesterday, it has 3 modes influencing the acceleration, I will try this option in current control on the lowest mode to see if it’s better on the rope tensioning before starting to pull

- I’m also building a long-range control with a Frsky R9m to control the winch myself in the water from very far away.

Any recommendations to ameliorate my system and configurate my Vesc are welcome

Thanks for reading me ![]()