That winking face is used in way too many arguments. Anyway , Jezza did make a mistake, apparently he is human, chill guys @Toto44 and @nice2cu

I would buy one Mantafoils. Thanks

After foiling with the 1.1kWh batteries for some time now I wanted more range. 15km was enough but more is better.

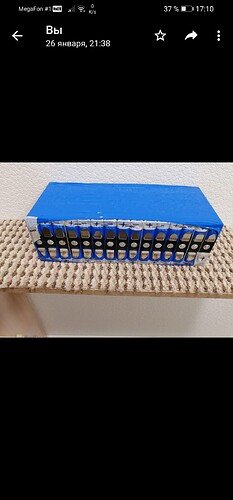

After some digging around I found this LGE63B pouch at 220wh per cell. So I maxed out my battery box dimensions that I could squeeze in my board. And installed 12 of these puppies, I’m now having a battery of 2.64kWh that can do high speeds for 30km long with ease. The BMS is on its way but with some care, I already made a test round.

The pictures are of the assembly and the box. The thermal picture is the pack after an hr of 50A continues. The box currently needs a lid but I’m waiting for the BMS to arrive first.

I would suggest to give little room for pouch cells. They tend to swell a little even if there is no issue with them

How did you connect the tabs together, any pictures?

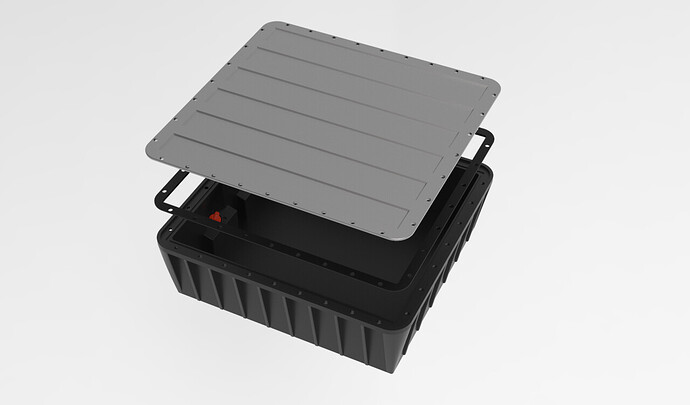

This battery is more interesting for its waterproof case case than for its cells (16s):

I know about the swelling, in the car where they came from very little to no pressure was applied so I thought we will see how it goes.

About the cell connections, when stripped from there pack the aluminium side had a copper strip welded to it. Therefore I was able to solder the cell ends together.

Anyone try LifePO4 batterry yet? And how to make a pack with it?

Yes. I ride them. But they are almost twice as heavy!

How many S and P that you packed?

And what kind of Lifepo4 that u used

But I have already answered someone that I would not go to these elements now.

Oh Great. How many minutes that you ride?

Maximum of 40 minutes. On average, about 40 amps. We need to try another screw and wings.

That one looks really nice!

In case you want a perfect fitting battery case…prepared for waterproof amphenol connectors similar to flite… check this out…

Battery case with seal

Hi @Kwinty ,

I just searched the forum for someone who has already successfully tried pouch cells. I happen to have some lying around, which I’d like to use for my E-Foil. The cells are 5000mAh each and I was planning to make packs of 6s2p, so 10Ah with 22,2V - just so I can still charge them with my RC- LiPo Charger. How do you charge yours?

One problem is that the tabs are made of aluminum, so soldering is nearly impossible. I guess I have to find a spot-welder to do the job eh?

Did you have any temperature issues with your packs ? Do I need to run some sort of water-cooling around the packs to cool them down ?

And how did you electrically seal or isolate the packs and especially the tabs ?

Sorry for all these questions after a year. If anyone else feels like answering my questions or has some thoughts or infos for me before I start making the packs - any help is appreciated

Hi @Jasey,

Thanks for the response. My cells are are (218Wh) 60Ah and have no issue at 50A ish discharge when close to 100A mine will get to 60°C so not suited for all day full throttle.

If you have a closer look at my battery tabs you can see that i soldered them, i was lucky enough that the aluminum end had a copper strip sonic welded to it. In your case spot-welding might work but is hard to do on bare aluminium.

My casing is 3d printed the outer housing and i double taped the cells together and at the end i wrapping them in kapton tape.

As for your 6s setup it works fine. I just went for a12s SmartBMS to save the whole splitting story. As for the cells i would go for a 6S4P since 10Ah is a real small efoil battery. And most likely wil not last you a half hour of foiling.

Good luck building and hope to see your progress lateron.

Thanks for your answer.

I wasn’t planning on using 12s2p batteries, but rather wanted to make smaller packs that I can charge more easily. I thought I could still contact multiple of those “smaller” packs to make a bigger battery, i.e. 4x 6s2p to make a 12s4p. I don’t know if that really makes sense though.

And for connecting the pouch cells, is there anything else you’d recommend if soldering and even spot-welding doesn’t really work? I also thought of gluing, but conductive glue is freakin expensive and bolting the tabs might be too bulky/heavy.

In any case, I’ll keep you updated, even if it’s just a “how not to do it”