Since I have already received questions about the battery from various people, I am creating this new topic here. @th3v3rn

I know it’s nothing new, but maybe it will help someone.

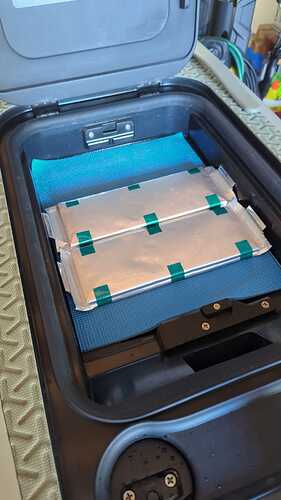

The battery compartment of the Fliteboard 1/2/3 is 390mm long, 305mm wide and 80mm high. It is important that it is not higher so that the hatch still closes.

Furthermore, the two corner radii must be taken into account.

At Ali you can get these beautiful ABS housings in 29x19x8cm for 30€ including cell holder and nickel-plated steel.

https://de.aliexpress.com/item/33017871879.html

These are ideal for small 1KW/h packs, for a reduced flywheel mass (like Flitecell Nano).

Two of the packs fit in the compartment but I really wanted to use 21700 cells. So I thought about how to build a simple and cheap case and came up with the following solution.

We all know how impact-resistant and indestructible polycarbonate is, at the latest after watching various YouTube videos (Hacksmith). It is also extremely cheap and very easy to work with.

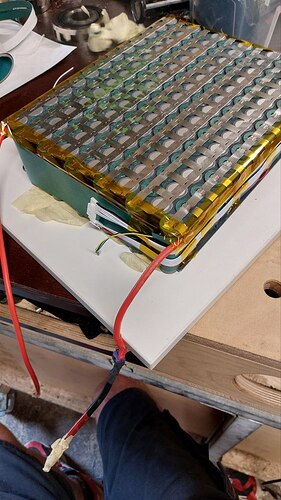

When I looked in my warehouse, I saw a beautiful piece of aluminium dibond. It would certainly also work well and dissipate the heat well, but it was planned for another project and the prototype had already been milled. The 21700 cells were packed with 0.2mm nickel strips, Kapton tape, fishpaper and heat shrink tubing, bringing them to 71.5mm. So there is still 8mm left for the lid and the bottom.

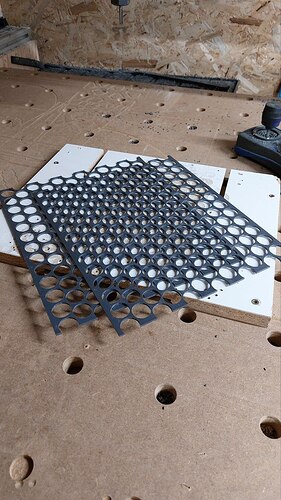

After a short calculation and a test I came to the conclusion that 3mm polycarbonate is sufficient.

I milled 1mm grooves in the two panels with the CNC and inserted a 1mm side panel. It can also be done with a normal router, the groove doesn’t have to be very professional as it is very flexible.

It is held together by brass sleeves with M4 threads. I had these lying around and they were cut to the right length on the lathe. If someone wants to rebuild it, just look for threaded sleeves or connecting sleeves, they are usually easier and simpler to get.

The side wall was simply glued with Sikaflex.

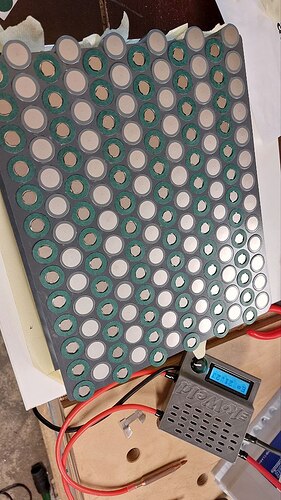

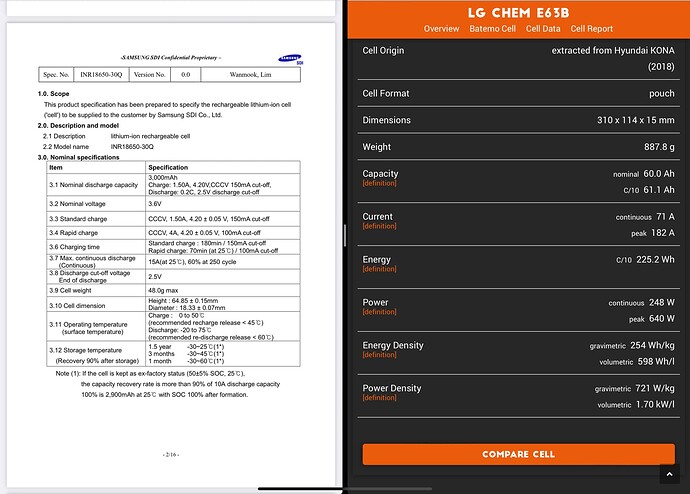

I chose LG M50LT cells because they are good value for money and deliver enough current.

Since I want to use the battery in all my boards, it is a little smaller 37x28x7.8cm. It is 12s13p, i.e. 2.85kwh, so I should not have any range problems.

The special thing is that the housing is very robust, can be built in 30 minutes, is cheap and you don’t have to laminate a box. Yes, it is modelled on the Flitecell explore, but with a weight of less than 1 kg it is not particularly heavy. The total weight of the battery is 12.4kg, which I consider quite acceptable. A maximum of 14s14p with BMS or 14s15p will fit.

Then you would have 3.5kwh at 15kg weight.

To save time, I also quickly milled the cell holders from 1mm instead of printing them.

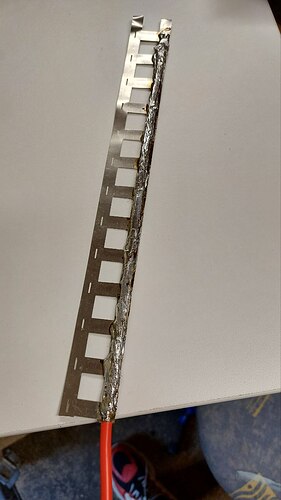

The busbar and the balencer connections are simply folded to the side, as is usual, so as not to lose any height. A 200A mini ANL fuse is also installed for safety.

The pack has now been used as a foil, jetsurfstyle and etow at 4600W continuous power. The cells have only warmed up by 3 degrees. So all is well. Smaller packs with 8p should therefore also not be a problem.