Hello everybody,

in this thread i will share the status of a efoil that a friend (@hanseaticfoiler) and me are building from scratch. From scratch means board, mast, fuselage, wings, … . This also means that it takes a lot of time. We started planning about a year ago with the first videos from @pacificmeister and joinend the builders board immediately. However we dont have that much time, and therefore we are not even halfway through yet. Another reason for sharing our progress is to put a bit more pressure on us to get the first prototype out there as soon as possibel ( maybe next year ;).

We started (very) technically by calculating all forces to get an idea of the size of the motor we need (see initial calculations on board size, wings, motor etc. - i can share the sheet if anybody is interested after a bit of cleanup and english translations):

The goal is to build a board that big that the buoyancy is enough for a person to stand on it ( we thought it might be easier to ride on it).

As a heads up: almost everythig you see here was a “first time” for us. So no experience with 3d printing, carbon fiber, styrofoam …

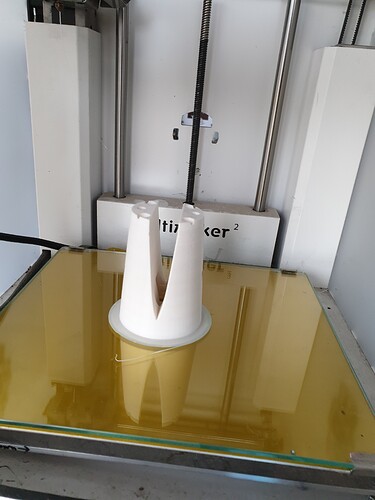

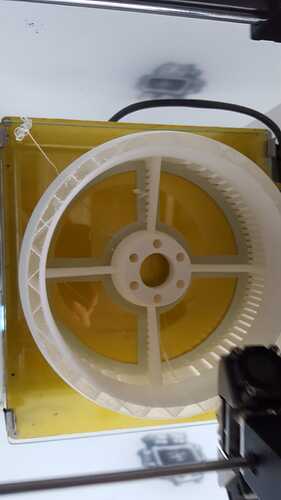

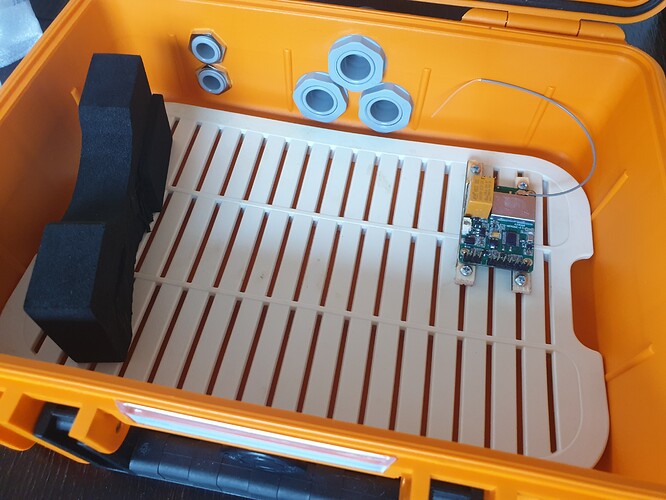

Chronologically we started building the mast. We saw here as well some people 3d printing it - we are having the same approach buildin 10 cm long parts of the mast. We experimented with printing settings, so almost every part of the mast has a different setting ;). Everything made with an Ultimaker2plus, pla.

Theory:

Practice:

You can see, that we introduced a cabel channel in the 3d printed parts of the mast. The cable channel ends in the 2nd lowest part of the ast and then “goes” to the backside of the mast. Lateron we have to drill wholes through the mas to get access to the channel again. All parst are basically made of the same material - the different color was just the material we had at the point in the 3d printer.

The plastic mast does not give any stability - we used carbon fiber (2 layers, 300g biaxial) ( + /Epoxydharz L + Härter GL 2 (210 Min.) + vacuum pump similar to thomas 2660) for stabily:

This is the current state of our mast. We will add two more layers, because it does not feel too stable right now.

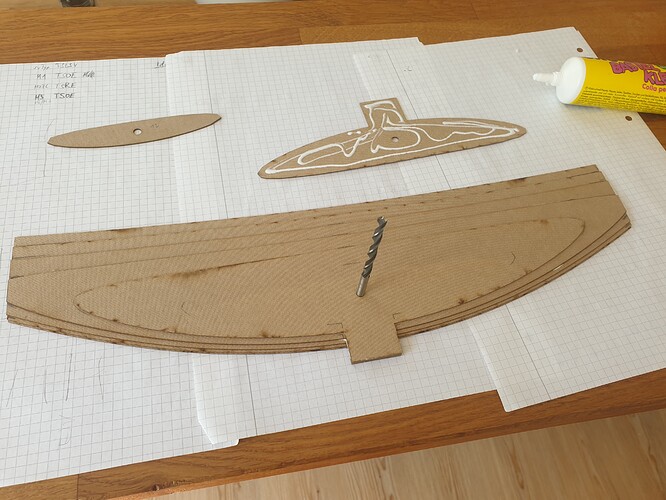

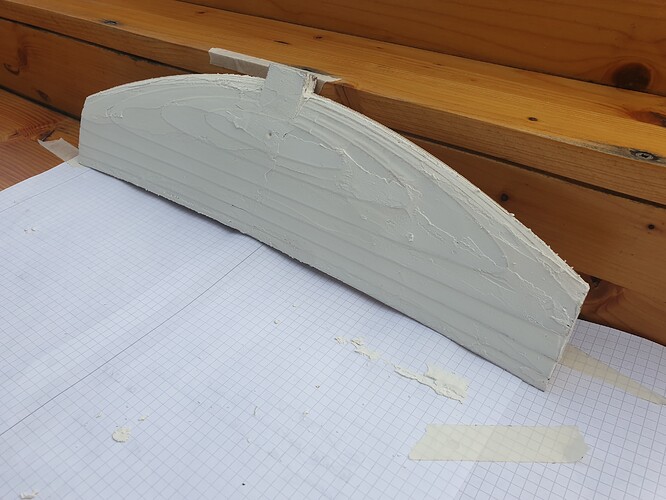

Now the board: We started with 4 large blocks of styrodur. We used a hot wire, and some lasercut profiles/shapes of paper. The finetuningwas done with sandpaper:

We will use stringers to distribute the forces from the mast to the whole board. We epoxied threads into the board, so we can screw the mast to the board later on. There 6 threads will give us 2 positions for the mast, since we are not sure which position is the best one: