my next board is going to be 125 x 60 x 12. do you think you can fit everything into 10cm?

what’s the depth of the box? this one looks like you cut through the bottom of the board…

@jeffM The shape result with your hot knife is really nice. Would you have a link ?

Q2 How many layers of fabrics of which weight ?

Q3 No hole between the US rails for the mast wires ?

Q4 Why do you prefer rails to 4x20mm wells between top and bottom skin filled with resin+micro spheres ?

maybe overengineering this, but you can perhaps use a Venturi style flowrate sensor?

it would be nice to see your battery setup. with 18650 the pack is at least 7cm high.

if you subtract the thickness of your lid (~1-2cm) you have a bottom thickness of 1cm left to work with.

i don’t think this could work.

when looking at your mast rail block it looks like this is at least 2-3cm high. how did you fit all of that into a 10cm board?

Not if cells are mounted sideways, or laying down, idk the word😏

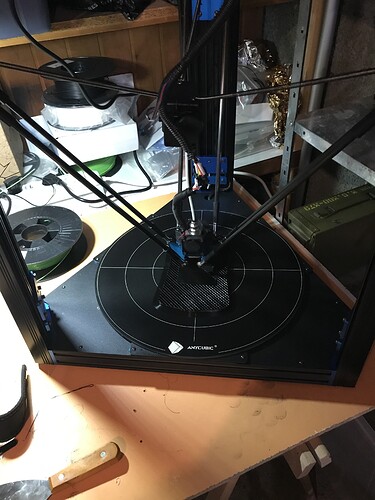

look above it is the same configuration as my V3

it is also 10cm high with the same US box

only difference the board is shorter

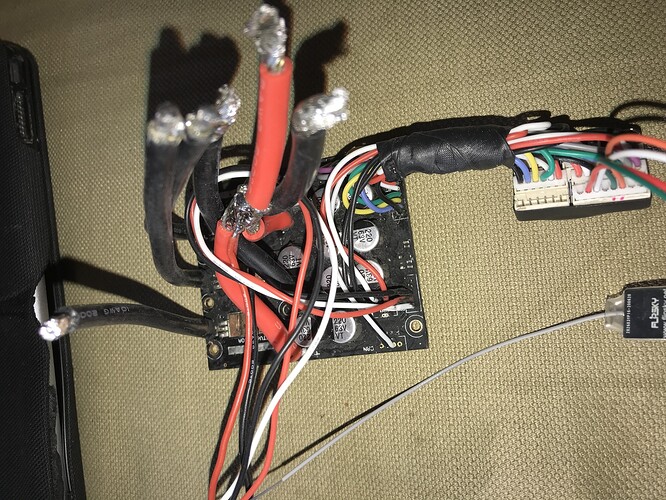

In your circuit design you have the magnetic switch to trigger the 12v relay which then triggers the kilovac. Would it not be simpler to use the magnetic switch to trigger the kilovac directly? Why use the extra relay? I’m still learning so I’m not aware of the benefits. Thanks

because the magnetic switch is normally open (didn’t exist in normally closed or I didnt find yet )

so the small relay is an inverter

Oh ok. Thanks. About the pump… you have it connected to the relay on the maytech reciever. Is that relay operated from a switch on the remote? If so, does that mean you have to remember to turn on and off the pump? Do you recommend using a pump over no pump?

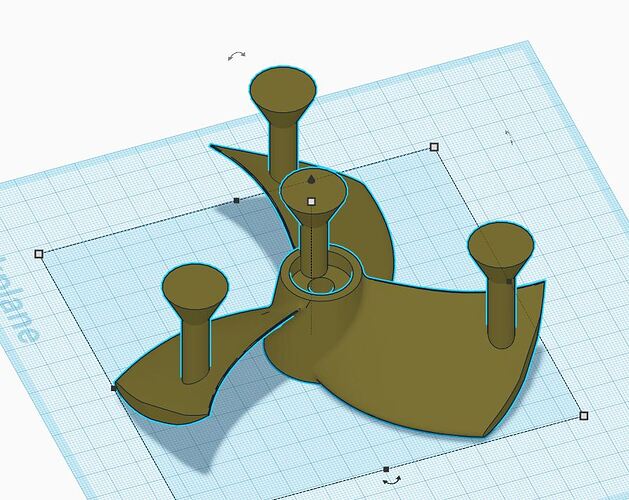

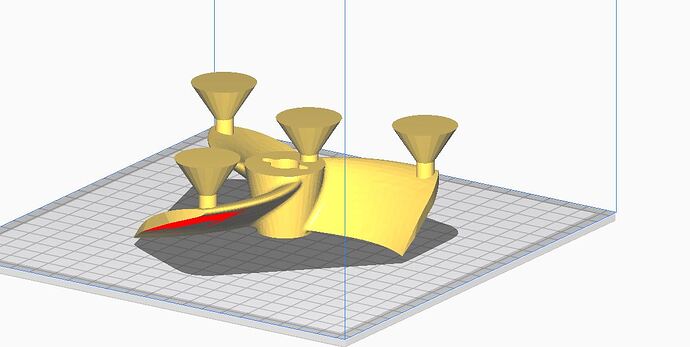

My first melted prop in PLA lost , failed ![]()

not too bad, need improvement.

There was still PLA in the blades

I have to leave the mold in the oven longer to remove all the PLA

I use ski poles, ski boot hooks, cans of coke ![]()

some pictures

Cool experiment to get an aluminium prop at the end. Keep on pouring

Eventually I would cast a more thin bladed prop, the PM prop isn’t that efficient due to the blade thickness and shape.

@Beninspain I know you had a go at aluminium casting, how would you improve this result ?

Jeff, Ben is the guy I mentioned earlier who removed his 12V pump (with the 12V UBEC as well) and installed a forced flow cooling outlet on his board deck to sense the water temperature using his toes.

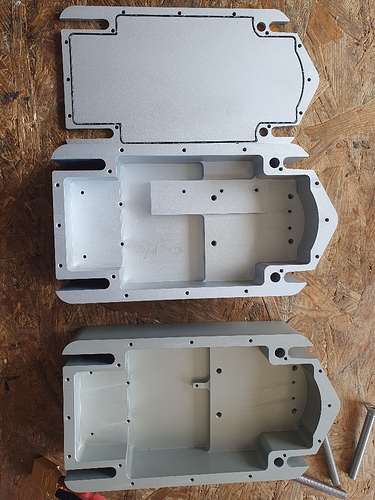

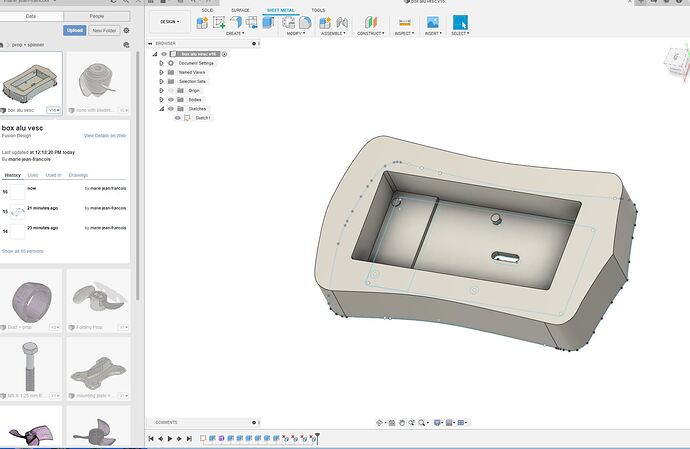

I found the solution to remove the pompe

Same solution like my V1 but with the VESC flipsky ( VESC just behind the mast )

In 1st I wanted to use the smart solution box at @ELEVATE.rocks

But for the V4 I want to reduce all the box

For sure I will use it for the V5 to test it

For the prop melt, i think I need to improve the process to remove the PLA, and the vent hole was not at the good place, not at the top of the prop

My second prop melded => success

after 1 hour of balancing

the original vs melded prop, I think it’s not possible to melt exactly the trailing edge, it’s too small

but we can have a thin trailing edge in post processing

Interesting, I would like to have an aluminium case as well but I don’t have (cost effective) options to CNC a VESC case for a gong mast adapter.

How do you plan on cooling the vesc with a plastic housing? I see you removed the watercooled casing, pcb only now?

who did you make the duct??

it will be in aluminum

the plastic box is the model to melt it into aluminum