That’s such a bummer!!! It explains why I’ve blown a couple. Haha. Well, time to find a better replacement. Time to fork over some money for quality stuff, still cheaper than the alternative.

There are some Flycolor HV pro 200 AMP but I found cheaper one on same base on this website :

I bought two for my towboogie to be able to set it to 67 amp.

I’ll keep you on touch.

The family … both 99usd

I mistakenly ordered the am32 version and I didn’t really like how it worked.

Are those 200A or actually 200/3 - 66A speed controllers?

I do not have any R/C or electrical engineering background, so when I see something rated at 120A(flycolor) or these at 200A, I expect to be able to pull that kind of power. I don’t think I am the only one here that thinks like that either.

That’s not right at all.

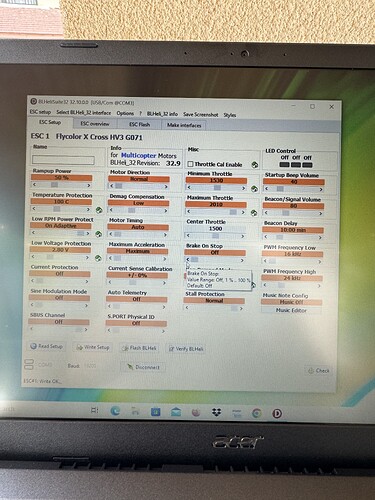

There are guys running the x-cross 160 at their limits and not burning them. It all comes down to settings and heat dissipation. For example if you turn on non-damped mode in blheli it will disable various protection settings on the esc.

In flycolors response you can clearly see he said you’ll get 120a at the phases if you set your current protection to 120a. That means when you start up on a foil you’ll see ±50% of the phase current at the battery, so 60a.

Could you please expand on the settings to run these maxed out without burning them?

I’m interested also, it will save money ! And if you know others tips like “non damped mode” , I’m keen to know because all this BLheli options are a bit weird for our efoil/foil assist/tow boogie application.

It’s not just about settings, they also need good cooling when you start pushing them. When I get a chance I’ll take a screenshot of my settings.

So there is no working temp protection on them? That’s a bummer, an esc that can’t protect itself is hit and miss at best.

Back to other options for me.

What does the blheli damped/non-damped setting offer in these applications?

This is from the manual for the X-cross HV3’s:

● Compared with the previous generation of ESC, better routing and component layout, built in current meter.

13.Temperature protection: It can be enabled or disabled. And the temperature threshold can be programmed The programmable threshold is primarily meant

as a support for hardware manufacturers to use, as different hardwares can have different tolerances on the max temperatures of the various components used.

16.Current Protection: Current protection can be enabled to limit current. If enabled, then current will be limited to maximum the programmed value

I think there is set-up error and also sometimes not adequate heatsinking.

I have run a few 120A esc’s (without any built in protection) but with additional heatsinks on full efoils and never had one burn.

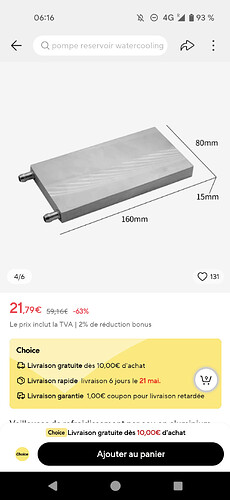

Additional radiators on both sides?

Yeah, I normally run on both sides and then connect the 2 for even heat distribution across the ESC.

You mean you’ve used a few flycolor x-cross or just any 120A esc?

Far less advanced escs when I started. All 120a without any form of temp protection, just with proper heatsinks.

I’ve run the APD 120a into thermal protection before when I didn’t bother heatsinking it so I know that if blheli32 is set properly it will shut down correctly.

There guys on the forum running x-cross 160a perfectly fine, then others not. The same goes for vescs and other esc combos.

What I noticed with my x-cross 160a was that the heatsink paste wasn’t as consistent as I would have done it, so it could come down to that too. Unfortunately I ripped parts off when removing the heatsink so I’m waiting for another before I can really test it properly.

I turned off current protection, set temp protection at 100 and adjusted max throttle to 2010 and had no issues hammering on it with my 27L prone board. It felt less wild than when I had current protection turned on

.

Flycolor answered me there is no current sensor on X Cross HV 2 and X Cross HV 3.

There is on X Cross HV PRO.

Does it mean you have just no possibility to read it by telemetry or does it mean the “current protection” feature is bullshit ? (they did not answer for the moment )

Anyway I will add active cooling with a cooler and water passing through stuck on both ESC’s inside my etow. No need on foilassist.

It’s a bit too anecdotal to be of much use here. Some ESC:s work, some don’t, but with the way esc manufacturers guesstimate and overpromise their ESC capabilities one “120A” esc is not comparable to any other in a relevant way.

I think that for efoils a robust and self protecting ESC is important since a breakdown at the wrong time can be quite critical. For foil drives, i guess a bit less critical.

Yes and No. It’s running components on the board that are spec’d well, so should be able to handle the power easily with good heat dissipation if heatsinked correctly. The power Mosfets (NCEP016N85LL) are actually better than most of the other 120A ESC’s I’ve run without issues.

I think reliability of electronics is critical for both. There are guys going further out to sea to do downwinding with foil assists than they ever would with an efoil. But with a DIY approach, its only ever going to be as reliable as the builder…