Thanks Andrii for the detailed reply.

So Duratec: low viscosity sealer, polyester primer and finish with vinyl ester gloss topcoat.

Thanks Andrii for the detailed reply.

So Duratec: low viscosity sealer, polyester primer and finish with vinyl ester gloss topcoat.

Thanks! I only get telemetry to my remote at the moment, VESC itself can somehow record logs but I believe it needs an SD card. I might purchase the iLogger or smth out there as well. Also the hatch is made of a thick fibergalss sheet so I get great connection at all times.

Yes, but if you don’t need class A surface finish then you can stop after primer sand the orange peel with 180-400 ish ( wet ), compound it, apply wax ( non-silicone) and spray PVA. Important: You must have the solid primer surface with no MDF showing off, otherwise it will suck the air in when you vacuum it.

Or if you can do an envelope bag then you could simply apply plastic tape over your mold surface and infuse that. Just remember to wrap the sharp corners with a breather to prevent making holes in your bag.

I love composite fabrication for having so many ways to achieve the same result, just don’t like the chemicals ![]()

Where are you putting your phone when logging vesc data. lots of us use it. I put the phone inside with the battery.

Don’t carry the phone with me just yet. My hatch is normally closed, so I would probably need an external bag…

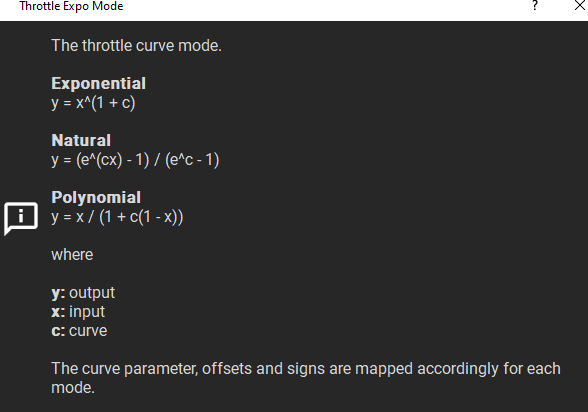

Here are some sneak pics of the data from VX3 ( no esc fan) . The throttle had very little range, so I adjusted the curve based on my current settings. Now 0-75% throttle is 0-50 A ( my speed range ).

@Andrii Congratulations on your beautiful work. I have hundreds of questions.

Thanks! Still a work in progress but it is taking shape slowly. Shoot them all, I would love to answer.

I am using Current control. It was determined that close to stall I am using 20A and about 50A at max. speed with this setup, which gives the useful range of ~15% between 10 and 25 throttle input. That’s a small range and it is hard to have adequate control over your speed. ( See graph below )

During the take-off the the power jumps up to 4 kw but not for too long in my case.

I decided to go with off the off-the-shelf wing setup and having the motor on the mast is the least problematic solution.

Unfortunately, during the last session, I noticed the water inside the VX3 screen. It is my second VX3 remote, as the first one had the same problem but Flipsky agreed to replace it.

I took it apart and noticed a few cracks in the corner of the transparent plastic case for the TFT , which could have leaked from there.

I removed the screen, filled the case with UV-stable epoxy, put it back to fully soak and applied a coat of RTV silicone around the case.

I am pretty sure that you can set the full throttle current to a lower value. Maybe 50A or a litte bit more. This way linear would have a more precise control.

About the wing: Do you have any positive attack angle between front wing and the board? Any negative angle on the stabilizer?

You are right, I should get away with 100A ( it goes up to 4kw during the take-off).

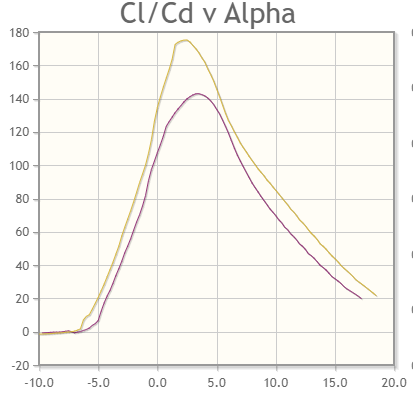

The wing I designed had 2.5 deg AoA as it would appear to be most efficient in my Reynolds number range and the stab had spacers to change AoA.

With these Gong wings, I don’t know.

I am using a kite surf duotone wing. But i pretty sure it has AoA Zero and I have to adjust it with shims. Having problems to take off and mantain steady.

Duotone Spirit Surf 1500cm²

I will try to add +2deg on the front wing. And maybe -2 on the stab.

Can you describe the problem with the take-off more in detail?

Steady in terms of roll or pitch?

What stab area is it?

@Andrii

Both pitch and roll are “unstable”, i have some experience with kite and foil.

Some videos of a frient : https://www.instagram.com/reel/C9-5P4fJ5wuV_0VUsth0Zut8wFt4o_Q3GyiNuo0/?igsh=N2szOHJpYzdyZnBr

@windego

Front wing 1500cm² (no shim) Stab 250cm² (1,5deg shim)

Flipsky 65161

Flipsky FSESC 75300

13s 27Ah 18650 HG2

Daly 100A BMS

Tested both with original flipsky propeller and a 3d printed True Glide Propeller

I have same motor with flite prop on 85cm gong v2 mast. Using the curve xl 1400cm2 and the xxl stab 355cms is ok for me. With the smaller suggested stab 322 it is more twitchy. Originally I got the smaller one of 275cm2 and I was having big problems.

I have the L wing coming as well as the stab extender to see how that all works. In your case I suspect a bigger stab would help like it did me. I think kitefoil setups may have inherent stabilty coming from hanging on to the kite…not sure abiut that just a guess.

Do you think add a negative angle on the stab could have the same effect as having a larger on?

I have not tried that but I think in theory that is an option. The gong stabs are fixed angle. Maybe some others have tried that approach.

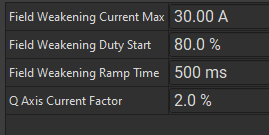

Tried Field Weakening and gained 6km/hr. At these settings was using about 3500W going 36km/hr but ESC/motor does not sound healthy.

Tried the Fliteboard prop instead of FR and got a significant improvement in power consumption along with a tiny bit more speed and lower vibration. Now at 30 kmh, the efoil consumes 1500-1600w, at 25 kmh - 1100-1200w.