Did you also purchase their prop?

No, I am using a foil drive three blade prop. I drilled and tapped the rotor to make it work with the Flipsky motor.

That’s strange, i agree with you. Could try to isolate the motor noise with a layer of rubber where clamp meets the mast

1: Run the motor underwater without the prop and see if there is any noise.

2: Try a different prop and see if there is a noise.

3: Check the balancing of the foil drive prop on the motor. You may have drilled slightly off centre and created a balance issue.

I agree the prop hole might be offcenter

Tried today Flipsky 6374 waterproof motor with their propeller. I am amazed how quiet it is, but bothers me that it vibrates the whole board when starting. When on speed or if given full throttle vibrations stop.

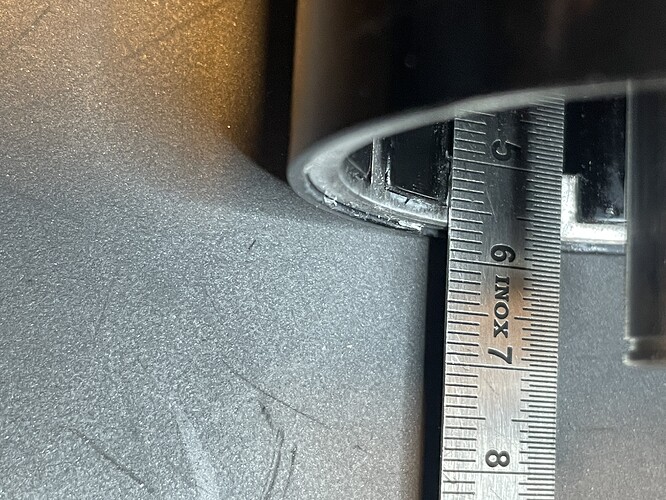

As if blades not open fully at first… Here is a video of propeller blades having not small mechanical play. Maybe this is the problem ?

Also it was difficult to remove the rotor after the session, I don’t know why…

My Foil drive ones have some movement as well. I use the Flpsky 6384 there us quite a different sound and vibration to the generic 6384. Think bearings as cause of lot of vibration and noise.

Good motors I use it with the 3 blade Foildrive 3 blade prop. but I do have one of the ones that you have coming in the mail so should be able to compare when it turns up.

How is the power and efficiency with the flipsky prop?

It felt strong and the same time smooth an quiet, can’t compare because too many paremeters differ vs rusty ali motor + 120kv + printed prop + old bearings.

But I will not use that Flipsky prop - don’t want to risk motor with these vibrations. Will print prop base 2 and 3 adapted to this motor holes. Have to share also new motor mount…

Update: It may be that replacing the ceramic bearings will stop the vibrations. Will check it.

Just received the waterproofed 6374. Can confirm the ceramic bearings have a lot of play and make an awful sound just by spinning it by hand… Will replace them with SS ones. I don’t know why they chose to use ceramic ones, maybe because the Saite one uses them?

To me the bearings look fine and sound pretty quiet too when turning by hand or in the water.

I tried now replacing the bearings. Replaced the 6900. Didn’t succeed to remove 6800, they are stuck in the surrounded epoxy…

I think, before destroying them to try surf like this.

But the problem is that getting off the the rotor is very difficult, it slides 1cm and then stuck. So it is the 6800 holding it, probably they are not aligned or something, probably have to remove them now…

My Flipsky motor is difficult to get the outer rotor removed from as well. I have found that pulling in a fast smooth motion while trying to pull perfectly straight makes a difference. If it gets stuck at the 1 cm distance I push it back in then try again.

The manta system uses this same motor. They run two ceramic open bearings and one stainless steel bearing similar to foil drive. They do not use the stock Flipsky ceramic bearings. Manta sells a two and three blade injection molded propeller setup that fits this motor. I really like their propeller design but the rest of the setup needs some work.

Why do you pull the rotor out after riding?

I think to rinse stator and rotor with fresh water.

Thanks; Do we have to remove the circlip under the prop to do so? Or just pull super hard? I have a 6384 by flipsky

It should pull off, then when returning hold it firmly so it doesn’t slam on, it does happen but I have never had issues.

Rinse, dry then spray with CRC lanolin or equivalent. Some people keep the rotor, the part that comes off, seperate all the time so it is dry, but most don’t.

There are pictures of people who don’t do anything and the motor can seize together, especially from salt water and force to separate will often break the bearings.

Before pulling hard, you need to remove the circlip. Should be ok to leave it without circlip, if you run it with a folding prop. With a normal prop people lost the bell and prop.

It worked! Thanks again. I think I ll go with mark’s suggested method to let everything sit in mineral oil for a few days.

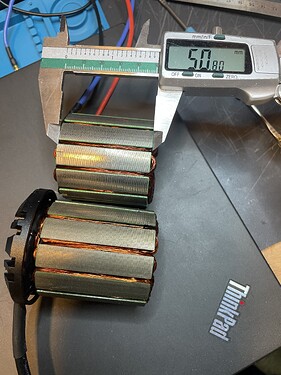

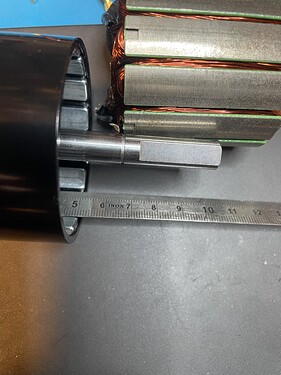

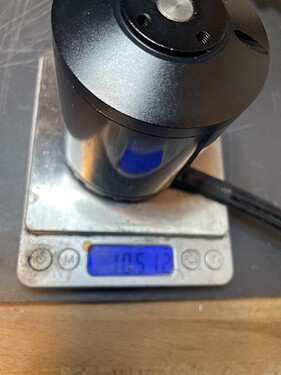

Hope it’s ok to post this here. Mechanical comparison between aliexpress 65$ bduav 6384 120kv and 6384 130kv Saite from alibaba (directly from Saite). The Saite costs around 140$ plus shipping. Incl tax around tripple the price of the cheap bduav.

Saite comes with 12awg wires which should be ok to use as is. I also got the Saite with the shaft already cut flush at the end of the bell. Rotor magnets seem to be coated although I did not ask for a waterproof version. Stator is not coated with epoxy.

Bduav needs new cables, they are too thin (awg 16).

Aliexpress bduav:

Saite 6384:

The BDUAV motor has the same stator length as the Saite 6374 version.