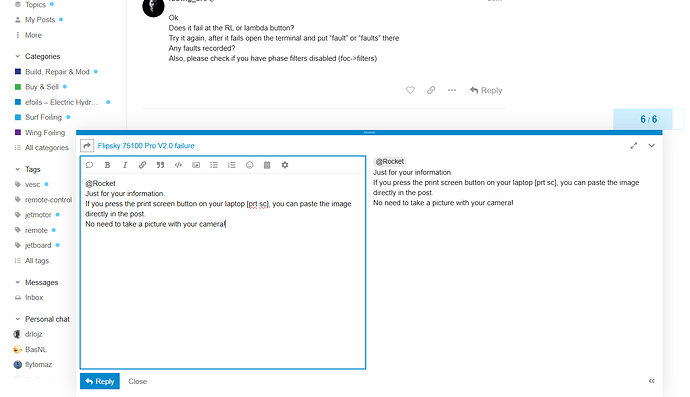

Hi All.

Unfortunately I am not having much luck with my Flipsky products. I borrowed a controller from a friend who had a spare while I am waiting for my replacement VX3 controller to arrive. And now the 75100 Pro V2.0 Vesc that was part of my build has failed.

I used the whole setup 5 times in total (3 times and the controller failed) and then twice more on a friend’s borrowed controller.

I used it for an efoil session with no problems. Then I went to the shower to wash my gear in fresh water and when I tried to get the motor to turn to wash the water out of it, the motor would not turn and made some strange noises and cogged back and forward a tiny bit.

Since then I have been trying to understand what has happened and by using parts that my friend has we have determined that something has failed in the Vesc.

My motor works perfectly with his Flipsky Vesc. And his motor has the same issue when connected to my Flipsky Vesc.

I have completely removed the Vesc from its casing to see if there are any signs of water damage or heating marks but nothing is showing.

The Vesc has definitely had no water ingress.

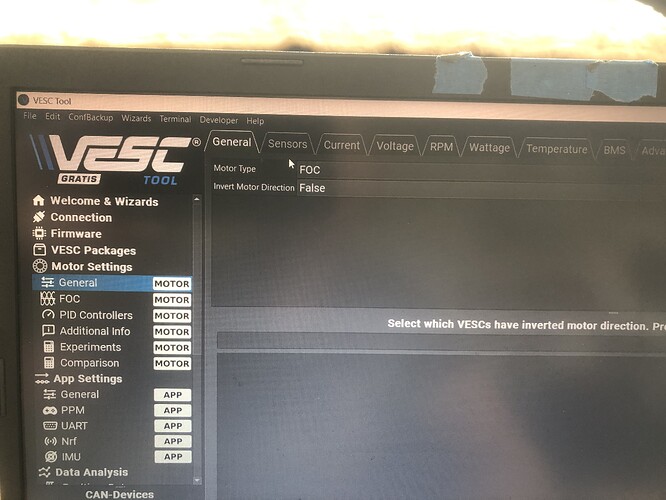

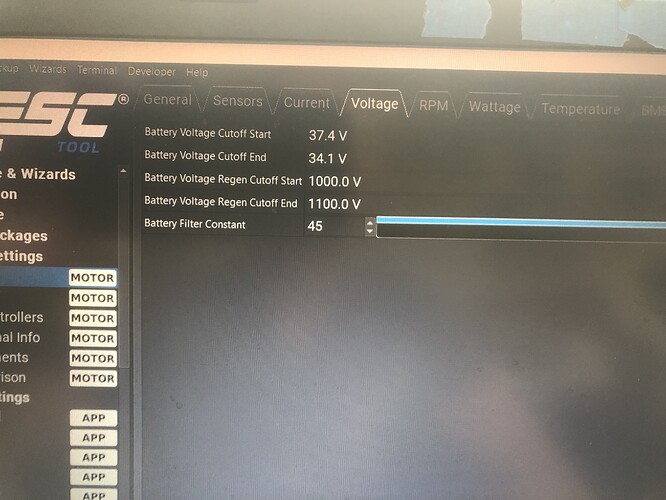

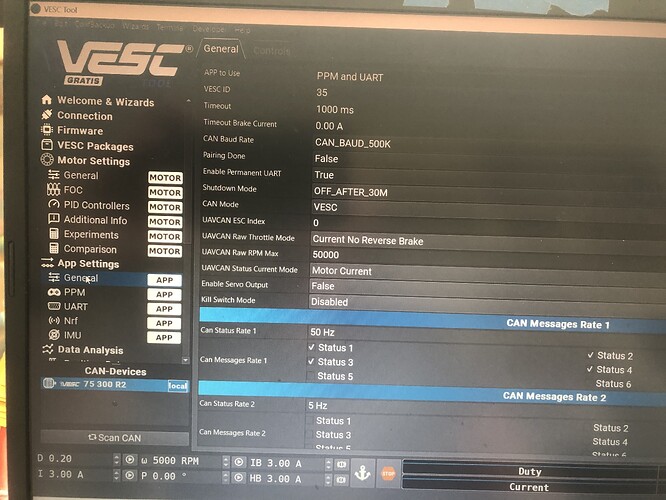

The Vesc still connects properly to Vesc Tool, the only thing that seems to be not normal is it doesn’t seem to retain the voltage figures in the general tab of the motor settings in Vesc Tool. Other than that it reads the motor and app setting and writes the motor and app settings.

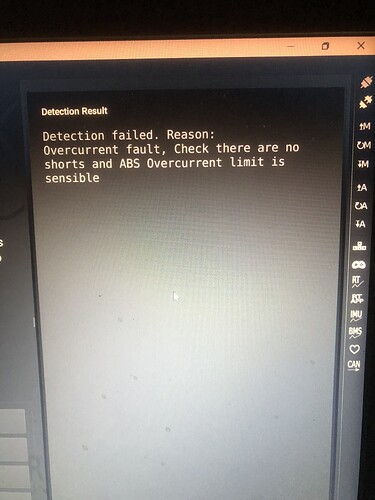

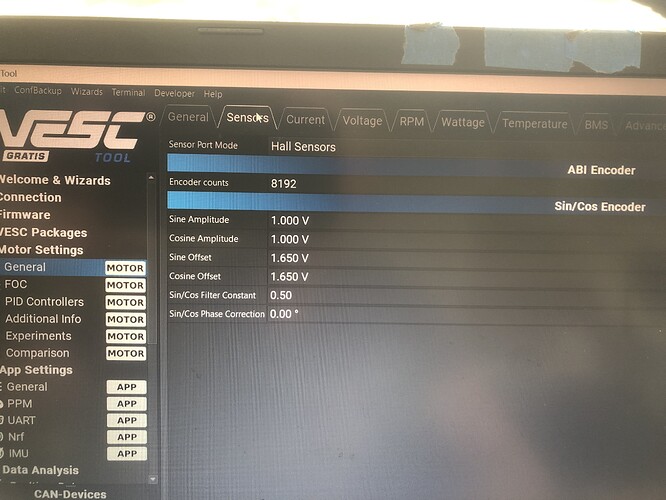

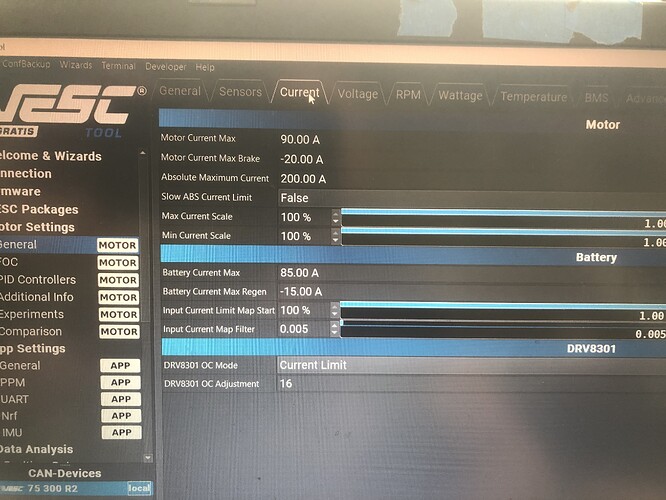

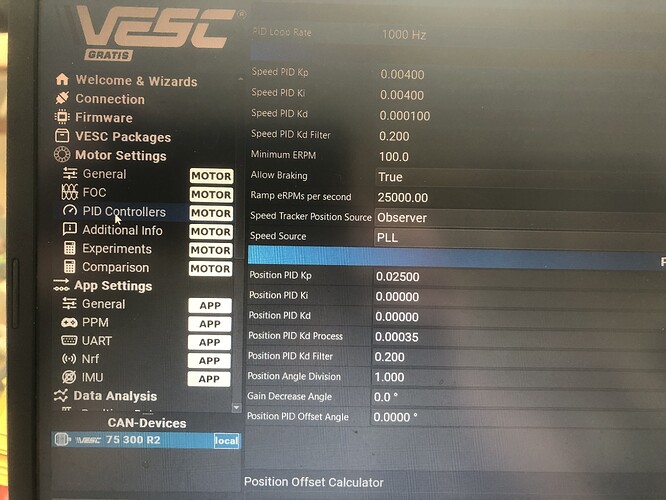

The main thing that fails is when you try and read the resistance and inductance settings. I have included a video of the inductance testing and photos of my motor settings.

If you try and use the setup motor wizard it goes through to the same area of testing and fails there also. Photo of that error included also.

I have only seen a maximum Vesc temp of 53 degrees once. Generally (used 5 times) it has been running below that.

If you watch the video you can see the green and blue lights work but then when it fails to read the resistance and inductance the light goes red.

The UART 3.3V and 5V read the correct voltages. The PPM 5V read correctly also.

I don’t use socket 2 (Hall) or socket 4 (Can+Power)

While sitting powered on both the green light and the blue light are on.

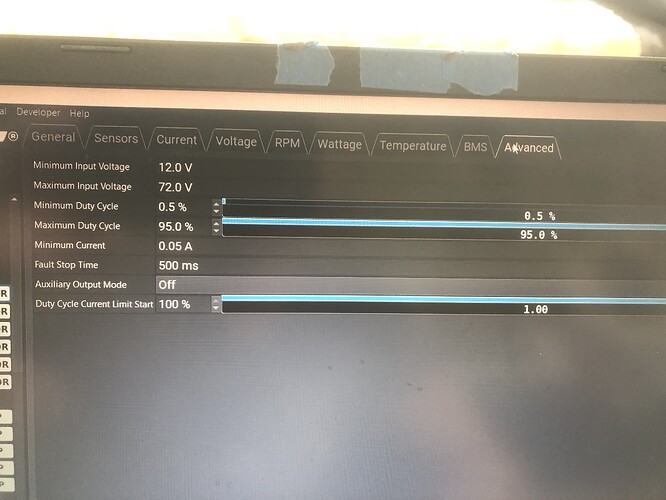

I am worried because I can find no reason for the issue. I would understand if water had gotten in there but no water. No cuts in wires. No strange electrical burning smells. Nothing. I am worried because I don’t want it to be something in my settings that has caused the issue. I have asked friend who are running the same setups and compared their settings and they are very similar they are actually running theirs at 110 amp max and I am only running at 90. they are heavier than me.

Has anyone else had issues with this Vesc that weren’t abuse, overheating or water ingress related?

Please let me know if there is anything else I can try or what can be done to to help me.

Thank you.

![#008-1: VESC Setup for eFoil [Flipsky 65161 & 75200]](https://img.youtube.com/vi/QaVPISP8BF4/maxresdefault.jpg)