Any feedback on circlip removal? As I’m used to the circlip being off and rinsing after each use in saltwater I’m thinking I’ll leave mine off.

hi

my old pod that fit nonames 6384 fits the flipsky one perfectly

Its the first this that comes off change. I do change out the bearings as well for plain stainless as well as had a couple of the ceramic fail over time. Coat with lots of protection on hub as the coating comes off pretty quick can lead to rust.

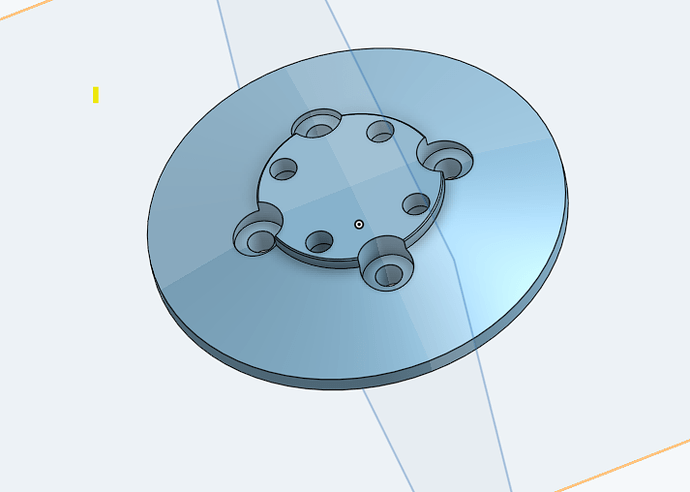

I just bought the 2 blade FD alu prop to put on the Flipsky motor (with added screwholes). Since the bell is flat, I see a potential problem fastening the prop, since only the outer edge of the hub will be in contact with the prop and the gap in the middle maybe causing the prop to become uncentered or loose. Has anyone tried this combo and is a shim needed?

Just 3d print a small circular shim to take up the space. When I get to my computer next week I can share the file if needed.

If you already have a file for it, that would be nice, thanks! ![]()

flick me your email will send you File that i Use

You need to put in some Heat set inserts these go in from the flat side for extra strength.

Been using this for last year no issues with the FD 3 blade prop.

Link For the STL File

mentioned in other threads but excellent QR motor pods and props that have holes for flipsky 63 motors can be bought here https://kparts-watersports.com/en/shop/E-FOIL-ACCESSORIES-POD-c159415759

Flipsky 6384 Long thread shaft (like 7070 or 65151) is available now!

Hi all ive been running the 6384 motor with maytech 160amp esc on 12s its been great until todays session at take off i noticed it was what it felt like slipping and would cut out if i gave too much throttle at one go. Then i noticed slight vibration. When i had a look the bolts came loose on prop. That explains vibration but not the slipping sound of motor. Any ideas?

not an expert here but a loose prop can cause esc motor control issues from back emf timing irregularularities caused by mechanical decoupling

Im think thats what it was today i went out and on the new 130 amp esc with flipsky 2 bladed prop.

everything went well no issues apart from my riding skills runs great noticed power delivery difference between 2 blade and 3 has more torque which i prefer so ill go back to that later. This today seems ideal setup for power delivery and run time

the link is not working. are you from china?