Sorry to be so pedantic ….

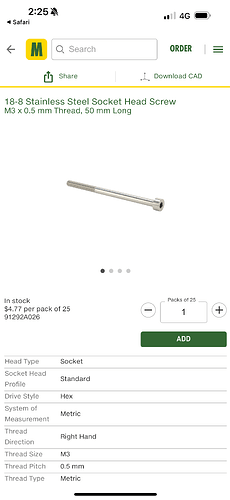

I’d use 304 or 18-8 with plain shank, get them longer like these ones and cut them down. Much better if the prop runs on plain shank. 304 is more malleable than 316 and they don’t corrode even used in salt water in my experience.

18-8 Stainless Steel Socket Head Screw M3 x 0.5 mm Thread, 50 mm Long

2 Likes

I agree. I inject expanding foam using this method with a mixing pen then coat exterior with epoxy to drive strength and minimum weight. I would use epoxy for a hub though

1 Like

That sounds way stronger and lighter! good idea. What kind of epoxy do you use, just regular surfboard epoxy. And a syringe to push it into the voids?

Just regular surfboard epoxy works fine, try to get something with lower viscosity. With 15% infill you basically just pump in the epoxy with the syringe, works really well. Some of the art epoxies are quite low viscosity.